Ever evolving, this Model A hot rod goes like a Bat Outa Hell

Erik Hansen built The Bat Outa Hell in his spare time while working at CAL Automotive Creations in Bennington, Nebraska, a shop he has been with for more than 10 years. He was still a new hire when he got to put his traditional hot-rod knowledge to work on the flathead-powered Checkered Past, the ’40 Ford coupe built by CAL Auto Creations for Ron Cizek that won the Ridler Award—hot rodding’s Nobel Prize—at the 2013 Detroit Autorama. Hansen was also heavily involved in the Buick Invicta that won the Al Slonaker Memorial Award at the 2023 Grand National Roadster Show. You might also recognize him if you remember the feature we did on the Omaha Coupe; Hansen helped to get it back on the road and was behind the wheel during the photoshoot.

Each year since the late 1940s, Bonneville Speed Week brings the promise of land speed racing to a salt flat in northwest Utah, organizing cars by engine type into classes that honor the genesis of hot-rodding as we know it. Even when rain soaks the dry bed of Lake Bonneville and records remain elusive, as they did in 2022, a migration of traditional hot rods rumbles into Wendover to celebrate the past.

This year, just as much as we were looking forward to racing, we were looking forward to seeing and riding in this 1931 Model A coupe, recently back on the road after a thorough reimagining by Erik Hansen.

This coupe wasn’t Hansen’s first hot rod. “I started building a rat rod with a flathead when I turned 16,” Hansen told us. Inspired by his great-grandfather, who rode a Harley-Davidson flathead to college and ran the local stockyards in addition to being a blacksmith, Hansen got to work fixing a 1924 Model T that had been sitting at his great grandfather’s shop for 40-plus years. The makeshift pickup was stock from the cowl forward and had an all-original Model T drivetrain, but it had sat outside in the rain for so long that the engine was locked up. The banger motor had to go, and the T became Hansen’s first flathead V-8 hot rod. It gave Hansen a lot of experience and also a desire for a traditional, racy hot rod. Ford’s successor to the T, the Model A, would be that car.

“I think I was probably 18 when I picked it up,” says Hansen, who is in his early 30s. The exact date isn’t that important to him, as the sad Model A he found in the early 2000s was never supposed to be the actual project—just a placeholder. The A had been dragged, unceremoniously, into a field and was full of brush. It seemed its last task was to serve as a dirtbike ramp. The sorry condition was no problem, because the price was right: For $100, Hansen bought the reference he needed to build a chassis for what would be his real hot rod, set to come at a later date.

Over the course of six years he replaced, piece by piece, all of the panels that were too far gone to be salvaged. The field-find began to resemble his vision of a proper hot rod Model A. Since he knew from day one that he wanted to run his Model A fenderless, Hansen built quarter panels from scratch, shaping 20-gauge steel on an English wheel. The new quarters raise the rear wheel arches to match the line of the tires and maintain their radius, much like the arches on a ’32 Ford. He also wrapped the bottom of the quarter panels underneath, curving them like those on a ’32.

“Model A guys are always trying to make it look like ’32 stuff because we can’t afford a ’32,” Hansen joked.

Hansen also made the doors from the beltline down as well as the decklid skin. Its inner structure is from Brookville, however.

Most of the roof is original, although Hansen had to massage it back into shape: When the body was pushed around the field where it previously resided, the roof had taken a beating. Hansen chopped the top four inches, giving the car a purposeful look while still leaving plenty of room inside the cabin.

Some of the quarter window steel is original, as Hansen found some Ford sheetmetal that was left over from an inventive farmer. Due to rationing during WWII, and because Ford stopped making commercial vehicles to shift to military ones, farmers often cut the roofs and decklids of Model A coupes and sedans to create makeshift trucks, a body style that offered more utility on the farm. Somehow, the quarter-window frame from one of those converted A coupes was passed down to Hansen.

After working in his spare time for six years, Hansen got the car on the road. He spent a lot of time with it, driving the car from his home in Nebraska to the Hot Rod Hillclimb in Colorado, to Austin, Texas, and to Dubuque, Iowa. He racked up about 20,000 miles over the course of three years, but he never really liked the way the A looked with the previous chassis.

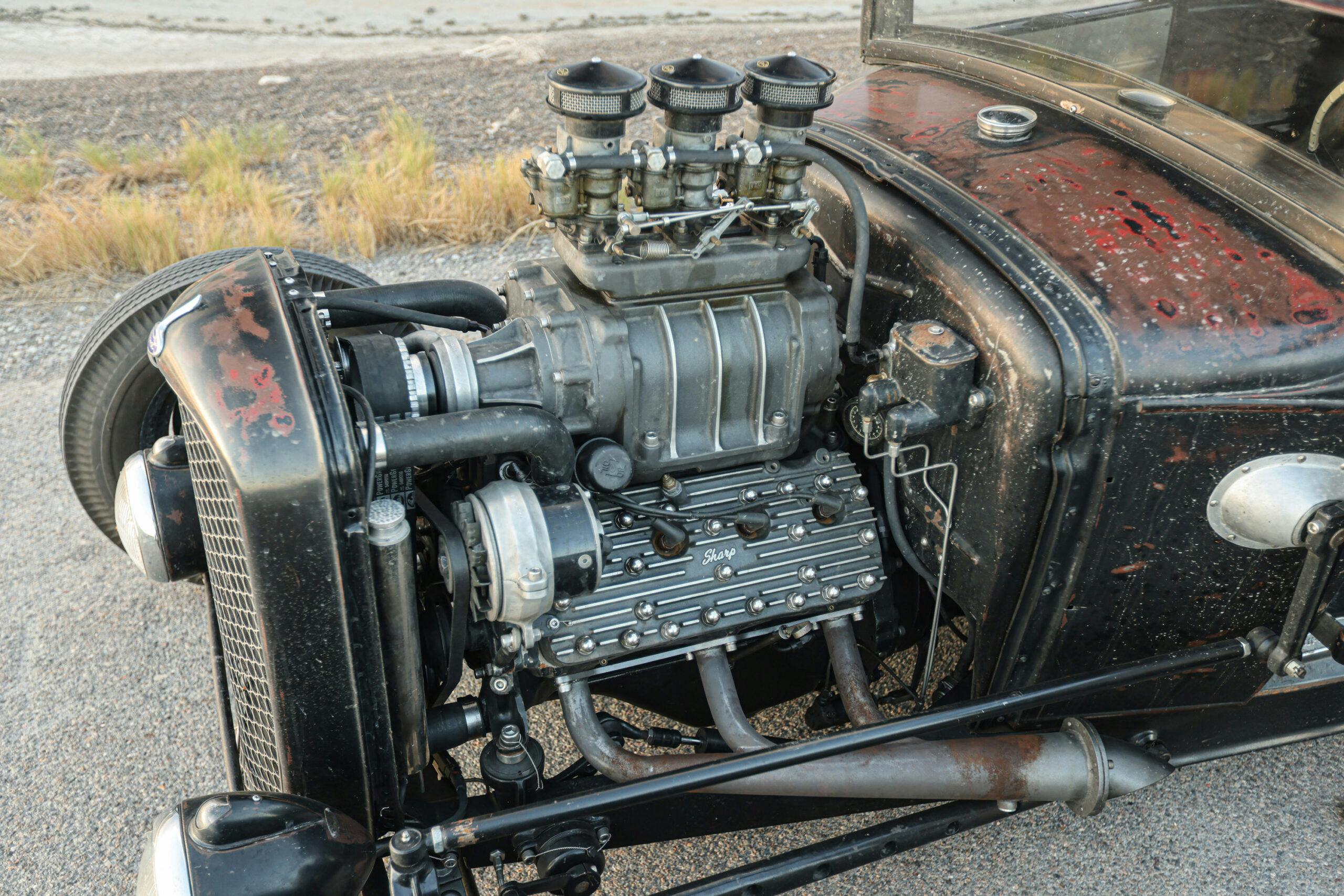

About three years ago, Hansen started this version using Speedway Motors ’32 Ford frame rails. The rails were pie-cut and pinched in at the cowl to be around five inches narrower at the spreader bar while also being kicked up an inch and a half to drop the front end. A ’32 grille shell was pinched to match. Both ends of the frame are bobbed, so there are no frame horns sticking out at the front. The rear of the chassis also angles up a few inches thanks to a Z in the frame. With the dimensions all sorted, Hansen added an X-member from a 1935–40 Ford and boxed the rails, setting the boxing plate just inboard of the ends of the C-channel to give him a place to hide hoses and brake lines.

There are lots of interesting things going on with the suspension, but the modifications are well hidden. The trickery is only really noticeable if you inspect what looks like a factory Model A shock: It’s really just a shell. Hansen gutted the internals and replaced them with bronze bushings that mount a shaft that has a bellcrank connected to a tube shock. Transverse springs—both Posie Super Slide—mount a heavy ’32 Ford axle up front and a ’57 Ford nine-inch in the rear. Both axles are mounted with a Watts link to keep the axles centered under the car, and both use an antiroll bar. Self-energizing 11-inch front drums and ’57 Ford 10-inch drums in the back provide plenty of stopping power for such a light car.

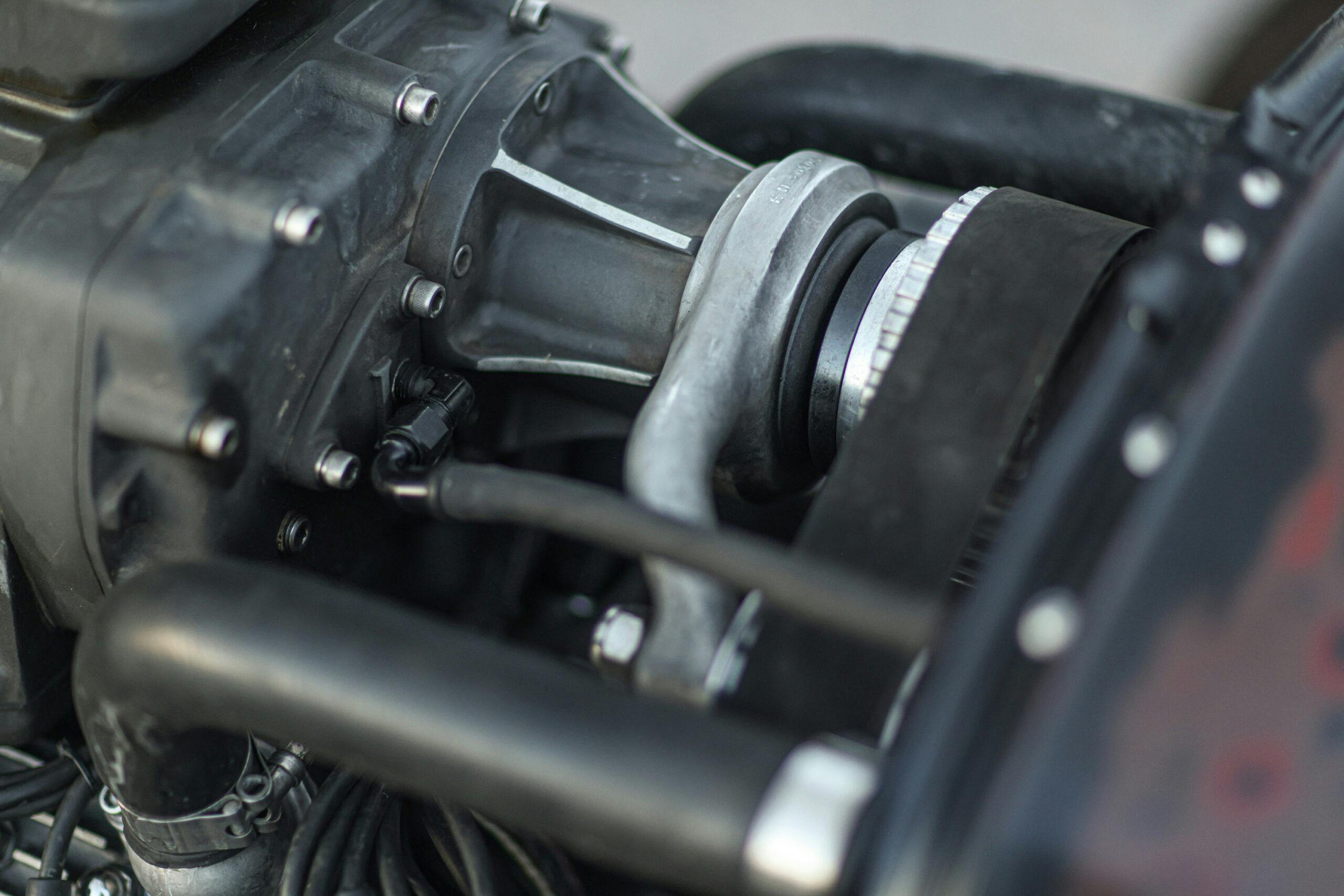

One of the few “modern” components Hansen used in the coupe’s build is the T5 transmission. This one, from a GM F-body, moved the shifter rearward in the cabin, which was just what Hansen wanted. The transmission’s .72:1 overdrive allowed for aggressive, 4:56:1 gears in the Ford nine-inch rear axle, a ratio that really let the flathead V-8 wind up in the lightweight coupe.

Front wheels are 16×4.5 inches, similar to those found on a ’40 Ford. They wear Firestone 5.50×16 tires. For the rears, Hansen chose “kind of an oddball”: A ’50s light-duty International pickup yielded a pair of 16-inch Kelsey Hayes wheels with a Ford 5×4.5–inch bolt pattern, and Hansen widened them to be six inches across. They wear 7.50-16 tires.

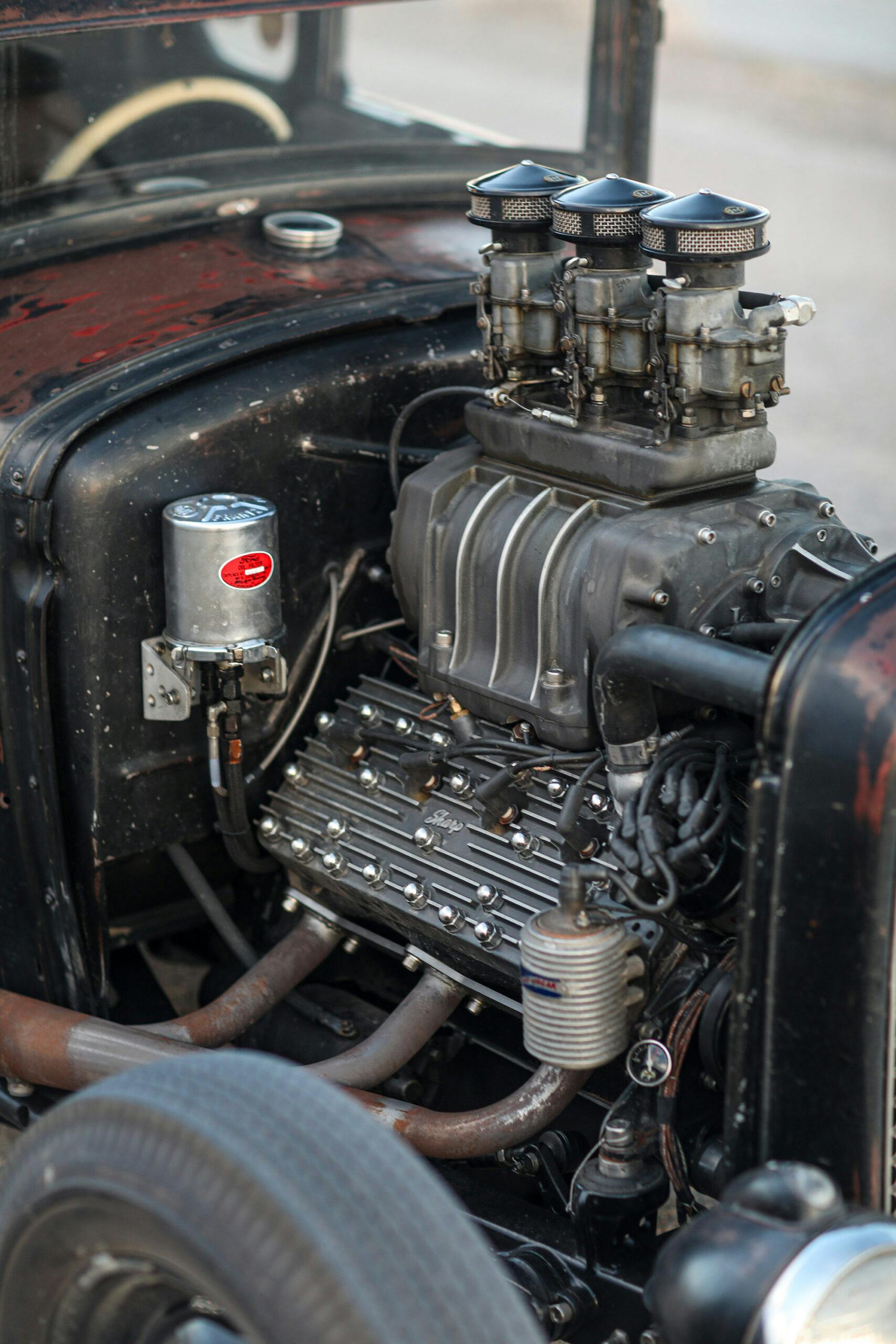

There really was no question when it came time to select a powerplant for the coupe: Hansen is a huge Ford fan and loves everything about the flathead V-8, from the engine’s aesthetics to its sound and, of course, its proven history in racing. This block is a ’49 8BA bored .060 inches over with a set of Aries forged pistons, a stock Mercury crank, and 8BA connecting rods. Displacement works out to 265 cubic inches.

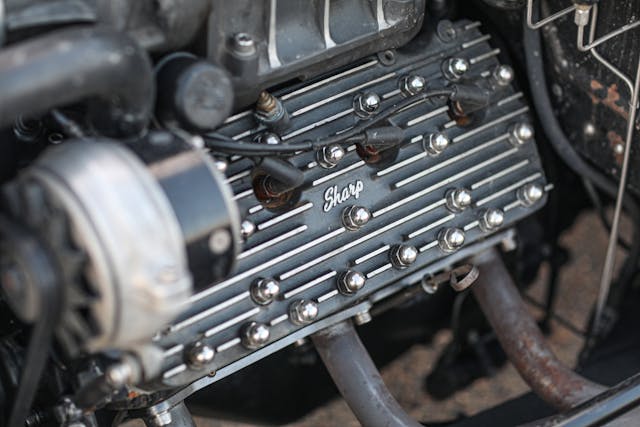

Sharp heads, pirated from a retired local dirt-track car, originally offered 9:1 compression. The heads were corroded and had some broken fins, but they still had the right look. Once Hansen welded them up and cut larger valve reliefs to help with flow and to drop compression a touch, they offered some big performance gains. A set of Cometic MLS gaskets seals everything up.

Hansen has modified the engine since the A initially hit the road. The first iteration of the flathead provided too much boost, and the cylinder pressure didn’t agree with the threads in the head. On a quick trip for lunch with a friend, as Hansen tells it: “I got on it and blew the spark plug. The spark plug wire held onto it and whipped it into the ditch.” Delayed but not discouraged, Hansen found the plug beside the road, cross-threaded it into the head, and got back in the car. He now uses a set of steel inserts to keep the plugs in place, and the blower is now underdriven to provide less boost.

To mount a supercharger on top of the flathead, Hansen started with an Offy four-barrel intake. He milled the top off and flattened it down to accept a one-inch-thick aluminum plate, which he welded in place and then milled to fit a GMC 4-71 blower. The blower is also a vintage piece, removed from a road grader that Hansen found in a junkyard. While he was milling the intake, Hansen added a burst plate in a hard-to-see spot, down low. If a massive backfire ever happens, the pressure has a place to go, and it won’t blast the blower off the manifold.

Hansen’s handiwork can be spotted all over the engine. Some of our favorite details are the front drive idler pulley and the generator/alternator mount. Each looks like it is cast in one piece, but only because Hansen put in a lot of effort. He tapered the belt tensioner in a lathe before heating it up in his forge and bending it into shape. The clamshell clamp for the generator/alternator he fabricated from several milled parts, welded, and then blended in the welds with a die grinder and sanding discs.

After the gaps and edges were even, the aluminum parts, including the heads, blower, and blower snout, were needle-scaled and then bead-blasted to make them all look like raw castings. Trail Performance Coatings powder-coated the blower and heads to give them a magnesium look. While you might think the fins on the castings are bare, they too are finished in clear satin powdercoat.

Holley 94s are Hansen’s go-to two-barrel. Their long production run makes parts easy and cheap to find, and he seems to have a knack for tuning them. The three carbs, each topped by a Grace & Co. air cleaner, use a progressive linkage that allows the flathead to run on the center carb for the first half of the throttle’s travel. That keeps the power manageable while fuel economy is a respectable 16–18 mpg on the highway. Not bad considering its aerodynamics, as Hansen puts it, are like, “a big parachute with that visor on it.”

He could drive the car cross-country and use just the center carb. Once the throttle passes 50 percent, the outboard carbs begin to open up. That’s when things start to get fun. “As soon as the secondaries open, the blower can become efficient,” Hansen says. The boosted flathead is good for about 300 horsepower, more than enough to be rowdy in a car that weighs around 2000 pounds.

The car is reinforced with a 1-5/8-inch DOM roll cage, made up from several pieces left over from the tube chassis used in a land-speed race car, a competition coupe built by CAL Auto Creations. Hansen doesn’t have any lofty racing aspirations; the cage is there “mostly just because there’s no wood structure left in the body.”

The shift boot uses upholstery from a ’57 Chevy project built at CAL Auto Creations. The owner brought in a beat-up original seat to get reupholstered. However, there was enough material from low-traffic areas to salvage and sew up a shift boot. That project also donated the bit of ’60s or ’70s tuck-and-roll vinyl that Hansen used as his coupe’s headliner. Both bits of material seem appropriate for the build. Even better, they have the perfect old-car smell.

This version of Hansen’s coupe, though recently completed, has already driven the 3000 miles from Omaha to Bonneville and back, with just a few teething issues. Overall, it seems that the time spent on the new chassis was well worth it: Hansen reports that his shop-brewed suspension is a great match for the car, and it drives just as he had hoped. “It handles phenomenally. I can just slide it around a corner,” said Hansen.

Ever the perfectionist, he’s scheming on future projects with the car: “I’m probably gonna chop it more someday.” Like any true hot rod, the Bat Outa Hell will never be quite finished.

***

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

What a cool car

Looking at the pics and reading about this car inspires me to get back on my own ’31 5-window project. Hansen is a terrific fabricator and has some killer ideas. As I look though the photos, I keep noticing details I previously missed, and I see things I might adapt in my own build. Awesome car!

What kind of power does it make? It would seem like it could be a handful at full throttle.

Gee thanks, David. What a great comment about this article… 👎

Agree with DUB6, get rid of adverts, thanks.

The XJ6 door release handles were a good way of getting “a bit of Brit” in the build and keeping it reliable. Actually I favor a lot of Brit in my own cars.

Beautiful car!

Amazing build. Thank you for pointing out some of the custom fabrication. Appears that every piece is special or has a story.