Troubleshooting a Car That Won’t Start

One of the topics I get asked about and over is the “My car won’t start” question. At this point in my life, I have my family pretty well programmed to not say “it won’t start” and to instead give the much more descriptive “it won’t crank” or “it cranks but it won’t start,” as such information is absolutely key to a diagnosis, particularly a remote one. I thought that, on this cold New England winter day, I’d lay out the basic car-won’t-start troubleshooting procedure.

A car needs three things to start: The battery needs to spin the starter motor, the fuel/air mixture must get sucked into the engine, and the spark plugs need to fire. Yes, the engine also needs compression and the ignition has to be timed at least in the ball park, but if the car was starting yesterday and it’s not today, the odds are it’s not due to those last two.

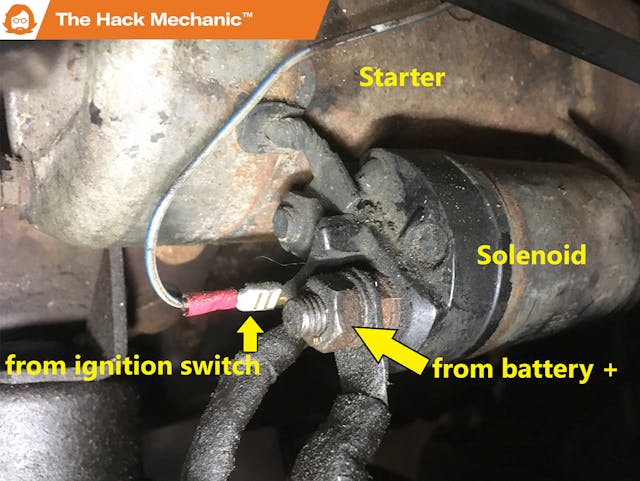

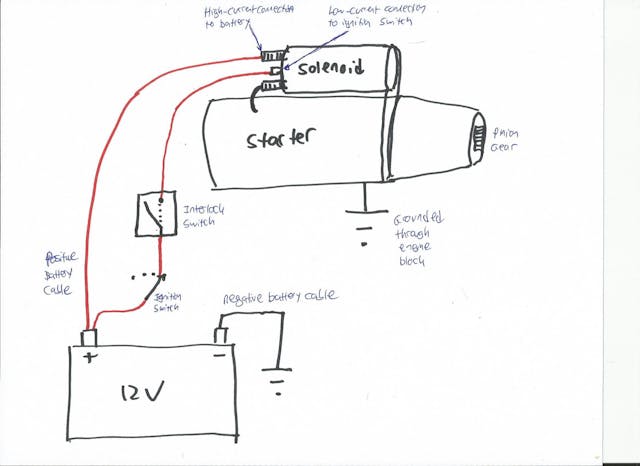

Let’s begin with the battery and the starter motor. The starter has two components—the starter motor itself, and the solenoid, which is an electrical relay that allows you to crank the engine without sending hundreds of amps through the steering column and ignition switch. The solenoid also has a little plunger inside it with a gear at the end that connects the starter to the gear on the outer edge of the flywheel, causing the engine to spin. For electrical connections, the solenoid has a long fat cable that’s directly connected to the positive battery terminal, and a short braided cable connected to the starter motor. The starter/solenoid are grounded by the fact that they’re mounted directly to the grounded engine, either directly to the negative battery terminal or indirectly via chassis ground. When the solenoid receives 12V from the ignition switch, it closes its internal contacts, allowing current to flow through the short braided cable to the starter motor and spin the engine. So if turning the key doesn’t spin the engine, the fault is either in the battery, the starter, the solenoid, the ignition switch, or the wiring between the switch and the solenoid.

By far the most common cause for the starter not spinning the engine, or spinning it too slowly for it to start, is a weak or dead battery. If you turn the key and hear CLICK but there’s little or no engine cranking, that means the battery has enough charge to energize the solenoid, close its internal contacts, and move the plunger/gear moving forward, but not enough for the starter to spin the engine.

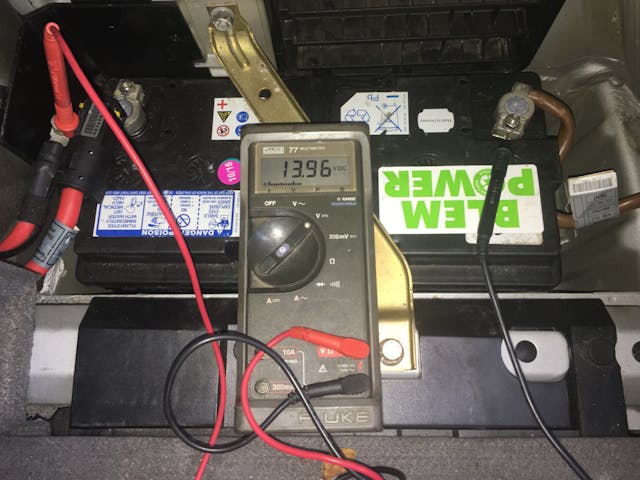

The first thing to do is check the battery voltage. Take a multimeter set to measure voltage (and if you don’t own a multimeter, just go buy one; auto-ranging meters can be had for $20 on Amazon), put the red and black leads across the positive and negative battery terminals and see if it reads the 12.6 volts that a fully-charged battery should have. As a rough rule of thumb, for every 0.2 volts the battery drops, the charge is down 25 percent, so by the time it’s under 12 volts, it’s essentially discharged, at least as far as the ability to spin the engine quickly. And if it’s down into the single volts, it’s deeply discharged. Now, it is possible for a just-recharged battery to read 12.6 volts and not be able to deliver sufficient cranking amps to spin the engine, but the best way to think about checking battery voltage is that if you find it’s low, you’ve found the source of the car-won’t-start problem.

If the battery voltage is fine but you turn the key and hear absolutely nothing, or hear one click and then nothing, and if none of the electrical systems in the car are working at all or are barely working (if, for example, the dome light is dim), the problem could be that the battery posts and the clamps at the ends of the battery cables are corroded enough to prevent good contact from being made. So before you pony up the $150+ it takes these days to buy a new battery, clean the posts and clamps with a battery post cleaner and try again. Also be certain to check the ground connections from the negative battery terminal to both the engine block and chassis. If one of these ground connections fails, electricity is forced to take the path through the other one, which can cause a no-crank condition.

If the posts are clean and the ground paths are good but even once the battery is recharged it still won’t crank the car, or only does so for a short amount of time, you can use a battery analyzer that use resistance as a measure of battery health. I’ve found they work pretty well. But really the gold-standard test is to remove the old battery, clean the clamps, and install a new or a known-good battery. If the car then cranks and starts, the battery was the problem. Note that, particularly in winter, due to low temperatures sapping battery strength and corrosion on the battery terminals causing high resistance in the contact with the jaws on the jumper cables, the failure of a car to crank with a jump-start can be highly misleading. Time after time I’ve experienced no-crank conditions that vanished immediately when a good battery was dropped directly into the car.

If the battery is dead, it’s crucially important that you figure out why it’s dead. If it’s winter, the battery is five years old, and the terminals are a corroded mess, then odds are that the battery has simply reached the end of its useful life. But if the battery is recent and it keeps running down to the point where it won’t crank the engine, something is making that happen. The cause can be that the car’s charging system (the alternator and voltage regulator and the wiring connecting them to the battery) isn’t working. As I say over and over, the resting voltage of a car battery is 12.6V, but with the engine running, it should increase by about 1–1.5V to between about 13.5–14.2V. So if you start the car, check the battery voltage, and still see 12.6V, the battery isn’t being recharged while you drive, so it will die on you again.

Other things causing a battery to drain can be that you’re leaving something on without knowing it, such as a trunk light or a power antenna. Or it can be a so-called parasitic drain where something subtle in the car is sucking power. Parasitic drains can be maddening. If the problem rears its head when the car hasn’t been driven for a week, sometimes the easiest thing is simply to install a battery disconnect switch, flip it off when you park the car in your driveway, and flip it on when you need to use the car.

If you know beyond a shadow of a doubt that the battery and its connections are good and you hear no CLICK when you turn the key, odds are that the solenoid isn’t receiving voltage from the ignition switch. You can trouble-shoot this in two ways. You can use a multimeter to check for voltage on the quick-connect tab of the solenoid when the key is turned to the crank position. If there’s not voltage there, the ignition switch, or the wiring between it and the solenoid, is suspect. If the car has an automatic transmission, there may be a problem in the lock-out switch that allows the engine to be cranked only if the selector is in the park position.

The other way to check the solenoid is to make a jumper wire with a quick-connect connector on one end, slide it onto the tab on the solenoid, and—after you set the handbrake and make sure the car isn’t in gear—touch the other end to battery positive. If that doesn’t cause the solenoid to click, then either the solenoid is bad or there’s not a ground path between the solenoid and the battery. If the solenoid clicks but the starter doesn’t spin, then either the starter is bad or the positive and negative current paths are corroded. Note that bypassing the ignition like this and feeding 12V directly to the solenoid is exactly what you’re doing when you use one of those trigger-style remote starter switches. Note also that there’s an old-school technique where, instead of using a jumper wire, you take a long screwdriver, touch the tip to the starter’s heavy-duty positive post, and lean it against the solenoid terminal to fire it. I strongly advise not doing this, as it’s way too easy for the screwdriver to slip and short to ground. A jumper wire accomplishes the same thing and is much safer.

If you’re certain that the battery and the current paths are good, and the starter won’t spin or sounds labored, and it’s hot to the touch, odds are that the starter has reached the end of the line. Once you have the starter out of the car, you can test it just to be certain by using jumper cables to connect the fat positive post and any convenient point on the case to a battery, and touching the post on the solenoid to battery positive. Make sure, though, to stand on it, as when it starts to spin, it’ll jump around.

Now that you have the engine cranking, if the car still doesn’t start, you have to deal with fuel and spark. While it’s possible for an engine to have both fuel and spark and still not start, odds are strong that a crank-but-no-start condition is caused by one of them. Let’s deal with spark first.

On an old-school vintage car with a single ignition coil feeding a distributor and plug wires going to the spark plugs at each cylinder, it’s a simple matter to pull the center wire out of the distributor cap, hold it ¼-inch from ground with insulated pliers, and have someone crank the engine while you check for spark. If you see it, then the coil is firing and high voltage is going to the distributor. Do the same test with a plug wire. If there’s spark going into the distributor but none reaching the spark plugs, the problem is in the cap or the rotor. If there’s no spark at all from the coil, odds are that the points have closed up, the condenser isn’t grounded, or one of the wires has come off the coil. There’s really not much to vintage ignition systems, and no-spark problems can always be solved via replacement of components with known-good ones. Suspect the points and the connections first, then the condenser, and the coil last.

On modern cars, it’s much more difficult to directly check for spark. Instead of having a single ignition coil feeding a distributor with exposed plug wires, most cars since the mid-1990s have had a coil-on-plug design (also called “stick coils”) where individual coils sit directly on top of the spark plugs in a recess in the head, so there’s no easy way to directly verify spark. While any number of things can cause a no-spark condition, a likely suspect is the crankshaft position sensor, as without that fiducial, the car’s ECU doesn’t know when to fire the plugs. If it goes bad, hopefully it’ll throw a code that can be read with a scan tool.

If you have spark but the car still won’t start, odds are it’s a fuel delivery issue. A quick and easy test is to take a can of starting fluid and give a blast down the throat of the carb with the throttles open, or in a fuel-injected car, into the throttle body. If the car starts, runs for a few seconds, then dies, you’ve nailed it as a fuel-delivery problem. The time-tested method is, with a fire extinguisher at the ready, to disconnect the fuel line heading into the carburetor and put the end into a clear bottle while cranking the engine. Sometimes you find a bad fuel pump, sometimes you find that a porous gas line is causing air to get sucked instead of fuel, and sometimes you find that the gas tank is full of rust and is clogging up the filter. You need to step through it, back to front, and find the problem.

On a fuel-injected car, care must be taken because the fuel pressures are much higher, but depending on the age of the car, you may still be able to disconnect the fuel line from the fuel rail, energize the fuel pump by cranking the engine, and verify that fuel is squirting out. At some point, though, most fuel-injected cars switched over from simple rubber hoses and hose clamps to dedicated fittings with crimp-on connectors, and instead of putting the hose end in a bottle, it may be necessary to use a fuel pressure gauge with the proper fitting to screw into the test port on the fuel rail. If there’s no pressure, then the fuel pump isn’t running. The problem could be in the pump or the relay that controls it. An enthusiast forum will usually have information on the location of the relay, enabling you to jumper over it (connect pin 30 to pin 87). If that doesn’t bring things to life, the fuel pump itself probably needs to be replaced or at least troubleshot to see if an in-tank hose has fallen off it.

If temperatures are cold and the engine cranks and has both gas and spark but it still won’t start, it’s likely an issue in the cold-start circuit. On a carburetor, this is the choke. The choke plates should rotate closed over the top of the carb, and the carb linkage should settle on the fast-idle cam so the throttle plates are partially open. On a primitive electronically fuel-injected car, there’s usually a cold-start injector in the throttle body that opens up to squirt fuel while the engine is cranking and for some short amount of time afterward. For troubleshooting reasons, it’s fairly common practice to either wire these to a little push-button switch or to connect them directly to the starter solenoid so you know they’re receiving voltage during cranking.

There, that’s most of it.

But don’t message me saying “HELP! My car won’t start!” I hate that. If I can train my wife and kids, I can train you.

***

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

Adding to the headlight on trick, If the lights stay bright, the starter circut has a bad connection somewhere, If the lights dim the starter is shorted.

Excellent article and comments!

I had a few big block GM engines that would start fine but after driving several miles and shutting off to perhaps run a short errand the engine would struggle turning over. It seemed like weak battery but instead was heat from engine causing high resistance in the starter. The engine would barely turn over, sometimes not fast enough to start.

Letting vehicle set and cool down, which seemed like an eternity, cured the condition and would start normally so as to let me finish the drive.

I don’t think I did anything about it, but I think others tried using heat shields between starter and exhaust manifolds.

So appreciate Rob’s columns! I absolutely support his idea for a battery disconnect switch and have them on my classic cars, not just to avoid battery drain, but to avoid potential disasters!

Had a 1970 Bronco that would only start while the ignition switch was turned to crank the starter motor. As soon as I let go of it, the engine would die. Looked through the wiring diagram to decipher how that could be and decided that the resistance wire was shot. Went down to the local Ford dealer and got a replacement that was close enough to the original in length. As soon as I got it all reconnected, the engine worked like a charm.

well written and easy to understand

Good article on some best practices and approaching it systematically – with some knowledge and safety. Given my “skill level”, glad I deal just with my old sports car, when it comes to “spark”.

BTW, it’s never been changed from (+) ground to (-) grd. But I can adjust around that.

Kind of late for this article, but I’ll add anyway…. Don’t forget that a well tuned and timed car takes less energy to actually start. Ignition timing is a big part of that. I have seen(had)cars that, intentionally or not, had the timing advanced far enough that the starter (and other components) had to struggle against the early firing in the cylinder. This can start to over heat all the other components, battery, wires, starter as the operator keep trying to start leaving them all less efficient, and the process degrading quickly. Check you static timing, advancing it for “more power” could be stressing your starter, battery, cable issues…