The curious case of the Sno-Runner “carburetor”

Book-smart is one thing. We can all sit in a warm spot and read any of the innumerable books that outline theory on automotive repair, including every service manual ever printed, and still not be very helpful when it comes time to pick up the tools and get work done.

Most engine tune-up items are easy targets for this kind of armchair diagnosis. It’s easy to say “just replace the points” or “give the carb a good cleaning” from the comfort of your La-Z-Boy, but in reality, those tasks are only simple if you have at least some practical experience. That experience is also called institutional knowledge and it can sometimes create an overconfidence that needs to be checked.

This realization came across my mind recently when a “carburetor” project entered my garage that I was confident I could address quickly and easily, until the part was staring back at me from a perch on my motorcycle lift.

After rebuilding seemingly innumerable numbers of the small carburetors found on mopeds, scooters, motorcycles, and any manner of yard implements, I rarely do any research before diving into a carburetor rebuild job these days. The real-world experience of having done it so many times outweighs the time I could spend reading a manual on the specific job at hand. Only rarely does this confidence bite me.

When I went to work on this Chrysler Sno-Runner, it did.

The Sno-Runner is an odd machine for a variety of reasons, with the main one being its origins. The late 1970s was not a pretty time for Chrysler, which desperately attempted to produce any product that could make it money. Someone in a boardroom saw all kinds of pitches and at the end of the day, with an exasperated sigh, declared: “The snow-bike thing. Build that.”

The result was the Sno-Runner. A one-person snow machine that packs a single-cylinder engine yoinked from the chainsaw assembly line of West Bend, which Chrysler had purchased in the 1960s.

Originally destined for saw use, the 134-cc, two-stroke engine put out 8 horsepower. Later in the production run, changes boosted the power output closer to 11 hp.

The second was the version that landed in the back of my van after a friend called me saying he bought the Sno-Runner off Facebook Marketplace because he thought it was cool. Of course, it started right up for the seller, but once the friend got it home, it wouldn’t run. He put in a new spark plug and tried starting fluid once or twice before deciding he was in over his head and that help needed to be called. Of course, I answered.

Confidently, at that. I brought the orange tube-framed machine back to my shop to make the work a little easier, but I told the friend the job wasn’t a big deal. Probably just some dried-up gunk in the carburetor after the machine had been left to sit for the summer. Take the engine apart, clean a few things, put it back together, maybe 45 minutes of work. The friend had the Sno-Runner’s service manual, but I wasn’t any too worried about needing it. A small engine with a carb—how hard could any fix be?

That’s when I noticed the fact that the sloping tube frame was also the gas tank.

That seemingly random observation lit off alarm bells in my head. That meant fuel wasn’t gravity-fed. This little engine had a fuel pump? That seemed absurd. But it had to.

Where would the pump go? How would it work?

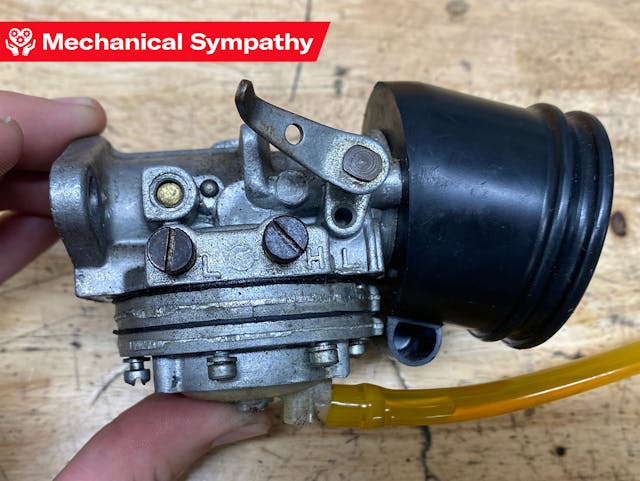

The answer is that a Sno-Runner has a fuel pump and a carb—combined. The fuel pump is part of the carb. Or the carb is part of the fuel pump? Whichever way you want to say it, the Tillotson 820A serves as both but I didn’t find that out until I stared at the “bike” for a while before retreating to the safety of the service manual to do some book learning.

The Tillotson name meant something to me, but only from the Model A Ford community. Many Model A owners happily ditch Tillotson carburetors in favor of the often better Zenith ones. Maybe this little engine was suffering the terrible Tillotson clog that affects Model As. The issue stems from the small horizontal passage in the bottom of the carb, which can get clogged so badly that it has to be drilled out.

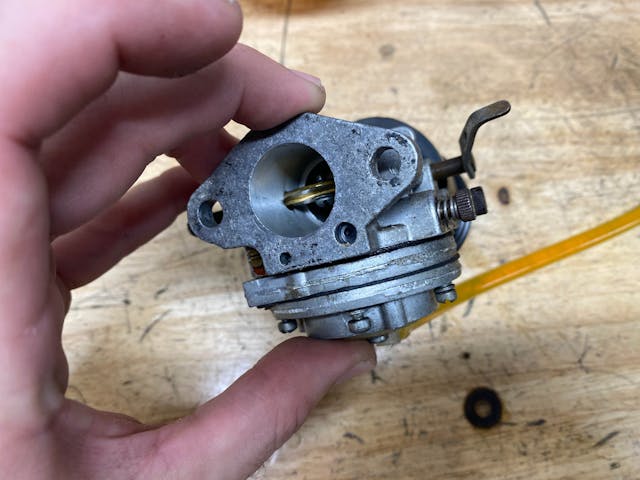

The diagrams told me that wasn’t the case. The “carburetor” is mounted on the engine case and lacks a float bowl and the myriad of passageways typical to an apparatus tasked with metering and mixing air and fuel as they enter the intake of an engine. Instead, there was a pancake clamped to the bottom of the intake throat, which was throttled only by a single brass plate. The arrangement really didn’t make much sense—until I read the manual’s description of the carb’s vacuum ports.

This is a vacuum-operated fuel pump that pushes fuel directly into the engine.

What a wild thing. The reciprocating motion of the piston causes the crankcase volume to expand and contract, creating a pressure swing that can be leveraged to do work for the engine. In the same way that a turbocharger uses the pressure pulses of exhaust gasses leaving the cylinder heads to spool its turbine, this Tillotson uses the cycling of vacuum and pressure in the two-stroke engine to operate a diaphragm in that bolted-on pancake, which pumps pre-mix up from the sloping tank.

It was all so clear once I realized this engine was designed for saw usage, which all but guaranteed it had to run in off-camber situations or, generally, when the gas tank was not located directly above the intake.

The diaphragm pulls fuel from the lowest point of the tank thanks to a hose, which is capped with a screened pickup, to make sure it stays submerged in any sloshing fuel. The hose exits the tank with a dry-break fitting that looks a lot like a basic air-line disconnect.

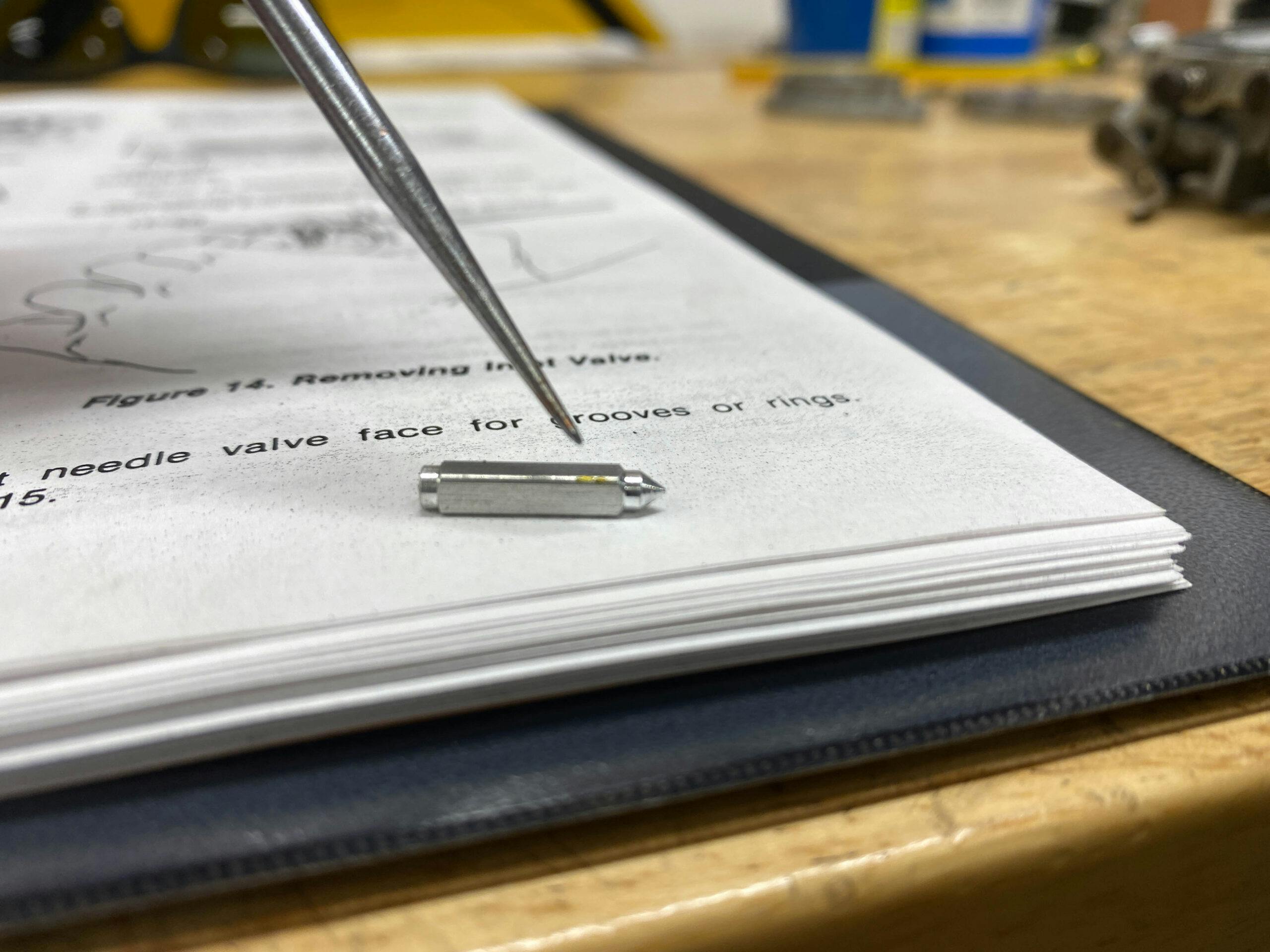

From that connection, the hose runs straight to the fuel side of that vacuum diaphragm before pushing fuel past a simple needle and seat and, as fuel enters the crankcase, into the airflow. A small bit of schmoo had trapped the needle in place and was preventing the fuel from pumping into the engine. A little spritz of aerosol carb cleaner and careful reassembly led to the engine springing right to life after a few pulls on the starting cord primed the pump and got the fuel flowing.

Could I have figured out this “carburetor” based on instinct from previous experience? Probably, but fixing it would have taken a lot longer and likely led to me doing at least one thing wrong and having to deal with the repercussions. That confidence, which usually allows us to dig into projects in a fun and effective way, stopped being a safety blanket and instead became a trap of my own making. Who would have thought that experience and confidence could be dangerous things?

I fall into ruts all the time with my garage projects. The rut comes from a desire to feel productive, successful. There are many parts of life where getting anything done requires real work and time investment. In the garage, the institutional knowledge I carry becomes my safety blanket and often keeps me doing the same handful of projects time and time again. The fact I have a veritable fleet of the same generation of Honda XR250R motorcycles built up in different forms should tell you something. It’s a shortcut to being able to pop out into the garage and take on a project with which I know I will be successful. That search for comfort projects stunts growth.

It was blind confidence that brought the Sno-Runner into my shop, but dropping that pride allowed me to leave in better shape than when I received it. That institutional knowledge might not be so dangerous after all—at least, so long as we don’t blindly follow it into ignorance.

I would have never learned about this odd mixture of fuel pump and carburetor if I didn’t step back and put the tools down to pick up the shop manual. Humility is as important as confidence in the garage. Of all the knowledge to be gleaned from a 1970s Chrysler product, I sure didn’t think it would be that.

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it.

“Carburetor is a French word that means, ‘Leave it alone.'”

Or so I was taught…

“Man made machines. Any machine that was made by man, can be fixed by man.” That’s what I was taught.

B-w-w-w-a-a-a-a-h-h-h-a-a-a-h-h-h-a-a-a-h-h-h-a-a-a !!!!!!!

It’s a large chainsaw style carburetor, which makes sense when you realize the engine is a large chainsaw engine.

Interesting. The “carburetor” is actually a crude form of fuel injection. Very ingenious.

I have owned a few Sno Runners and Rokons which use an older version of same motor. Number one reason they start hard (or not at all) is the crank seals. If you find an original, plan on doing them. The early westbend motors had points so its best to replace them with the little electronic ignition. The Sno Runner fuel pickup hose can harden and break too. They are fun machines!

Interesting. Makes sense when I think about it considering the pressure change in the crankcase is what pumps fuel. If those seals are bad the pressure fluctuation will likely be too little to work as designed.

I thought the fuel pickup hose would have been junk but this one was still supple. Likely replaced, but the previous owner cared for this machine!

Clever little bugger, though – and you got it to work. One thing about this kinda stuff, there’s always something to discover and learn.

Been fiddling with SU’s for 65 years,

do I know much more now, not much.

Carb Pump? Fuelburetor? I gt with FB myself.

Looks pretty cool.

It’s called a ‘Regulator (or diaphragm) Carburetor with integrated fuel pump”, They were also available as a “regulator carburetor” with no fuel pump. Harley used one (without pump) for a few years – on the FLH? not sure. They were very common (with pump) on snowmobiles in the ’60s, ’70s, and maybe the early ’80s as well as on early watercraft. Tillotson was also not the only manufacturer. Mikini made them as well – and also, as well as Walbro. Interestingly, the same HD series Tillotson that came on a 28HP 2 stroke single will run a 110HP 6 cyl 4 stroke like a Corvair. The smaller HR series was used on smaller engines and sometimes in pairs on 2 stroke twins up to around 40HP

Well, this brings back some memories…I worked at Chrysler Marine, Hartford, WI in 1977 when the Sno Runner was in development. My job was to dis-assemble it and draw all the parts in 45 degree isometric exploded views for the parts manual. Used ink filled technical pens with shape templates and French curves on an old school drafting board. (My how times have changed!) Also did many pen and ink illustrations for the operator manual. Wasn’t long after I finished this project that Chrysler fell on hard times and I was laid off. Oh well. On a side note, the building that housed Chrysler Marine in Hartford was originally the Kissel car manufacturing facility. Think I remember hearing somewhere that Amelia Earhart drove a Kissel car. Now I’ll have to go and Google this! 😂

Yes, she did, and I believe it was a Gold Bug. She was inordinately proud of the car, which she owned before her “aviatrix” days.

Those carburetors were exclusive to most early makes of snowmobiles also. For parts see your vintage Ski-Doo dealer……..

“Humility is as important as confidence in the garage.” Well said Kyle.

Interesting how lessons / insights discovered in the garage can (and often should) be applied to life and the general universe beyond the confines of our garage / shop walls. In this case, as in most things in life, trying to maintain a healthy balance of each is a good thing.

All that said, of course, based on the assumption that we have a life outside our garage / shop. Hmmmm 😉

Having worked at a Ski Doo snowmobile dealership in the 60’s and 70’s, rebuilding Tillotson carburetors was standard fare in the fall time of the year. The best way to ensure all carburetor passages are clean is to remove the welsh plugs in the carburetor body. Teduious work, but it is the only way to get as new performance.

Fun story and brought back my days and years of working on what we always called “pumper carburetors” back in the 70’s and early 80’s. Very common on many snowmobiles and other small engines at the time and like clockwork they would get all gummed up during the off season and require cleaning and often replacing the diaphragm. They were simple but a very effective way to “pull” fuel from a tank that wasn’t gravity fed. Great story!

Model A Fords came with a Zenith carb as standard and many people fitted an aftermarket Tillotson.

I saw the picture and instantly thought Lawn Boy lawnmower carburetor