Zero to 330 mph in less than 4 seconds sounds impossible. It isn’t.

A machine that looks like the offspring of a Batmobile and an exotic sports car rolls toward the starting line. It’s known as a funny car, a beast that competes in drag racing’s top class for full-bodied cars (as opposed to exposed-wheel dragsters), and it’s going to perform at a level that automotive engineers once considered impossible.

Crew members wipe the tires as the driver focuses on the task at hand. Staging lights illuminate: the race official pushes a button, three yellow bulbs flash, and the throttle opens. All hell breaks loose as arc-welder-level spark from 16 plugs ignites gallons of nitromethane fuel pouring into eight cylinders of the 500-cubic-inch engine. The clutch gradually applies, according to a predetermined script. The supercharger packs in massive quantities of air, and more horsepower than any conventional dyno can measure hammers the huge tires. Sonic waves cause the air to vibrate, and those standing near the starting line feel the earth move under their feet.

The huge tires distort, squat, and grow as the car rockets down the strip. Battling forces up to 5 g, the driver struggles to keep the car in the lane. Should the tires spin, the driver will pedal the throttle, but if engine speed increases more than a bit, too much fuel will put out the fire in one or more cylinders. If the thrust generated by the rear-facing exhaust becomes off-balance, the car will veer. If the engine suffers a lean backfire, or a dropped valve, the car will explode in a ball of flame.

Should all go according to plan, a thousand feet downtrack and less than 4 seconds later, the 2600-pound machine will reach a speed of approximately 330 mph and trip the finish-line lights. The chutes will come out, and the driver will breathe for the first time in about five seconds.

Internet sources have it that the Bugatti Chiron Super Sport‘s 16-cylinder 8-liter quad-turbocharged beast of an engine is the world’s most powerful automobile powerplant, generating a whopping 1600 horsepower. That may make the Bugatti’s W-16 top-dog among production engines, but in the wide world of all things automotive, it’s a docile puppy.

The engines that power Top Fuel dragsters and funny cars generate more than 10,000 horsepower from an eight-cylinder engine displacing slightly more than 8 liters. That’s amazing, but so too is the fact that these earth-rattling powerplants are based on an engine design developed by Chrysler engineers more than 70 years ago. The granddaddy of internal-combustion drag-racing engines is the Gen I Hemi of ’51–58, followed by the larger-displacement and better-breathing Gen II of ’64–71.

While nitro-burning supercharged drag racing engines set benchmarks for performance, they fail in a test of reliability and efficiency. Today’s fueler engines must be completely rebuilt or replaced after about four seconds of open-throttle use, and the 14 gallons of nitromethane they’ll burn while completing each sub 4-second 1000-foot pass sells for $45 a gallon.

Although Chrysler pioneered the configuration of the drag racing engine, its amazing power is largely a product of backyard engineering. Developed through more than half a century of experimentation and tinkering, the engine is the product of great minds, self-taught engineers, and obscenely violent explosions.

The first step on the path that led to today’s engine was recognizing the potential of nitromethane as a fuel. That was an unlikely leap, because the explosive liquid was originally developed as a solvent used to clean printing presses. If you drop a match in a puddle of nitromethane, it will likely go out. It doesn’t generate as much energy as gasoline, but it contains oxygen, so it can burn with less atmospheric oxygen than gasoline. An engine can burn approximately 8 times more nitromethane than gasoline on each power stroke. When all the numbers are sorted out, nitro produces more than twice the power of gasoline when combined with the same amount of oxygen.

The racing history of nitro is a bit fuzzy, but 1930s German grand prix racers were probably the first to burn it in an automobile engine. Tether car racers picked up on it soon thereafter, and drag racers experimented with it in the early ’50s. Running a large percentage of nitromethane was not an option early on, as it was unpredictable, but early racers discovered that 10–20 percent nitro mixed with methanol produced a powerful, manageable fuel.

Step two was the Roots supercharger. Early drag racers cribbed superchargers from GMC diesel engines. Rumor has it that some aspiring racers would sneak into the Chicago Transit Authority’s maintenance yard at night and liberate superchargers from city buses. No one will verify that story, but those early huffers had to come from somewhere, and the racers weren’t buying them new from GM.

Today’s superchargers are manufactured of exotic materials to exacting specs and can push far more air into an engine than the bus blowers of yesteryear. The most successful drag racing teams have supercharger dynos that test the output of each unit before it goes on an engine, and the blowers are subsequently examined and recalibrated regularly—if they survive.

Back in the early ’60s, racers found they could produce 1000 horsepower from a supercharged Chrysler Hemi without resorting to high percentages of nitromethane and an abundance of blower boost. But as the sport evolved, competition became fierce. By the mid-’70s, the best funny cars were clocking 220 mph in a little more than 6 seconds, and appearance money became more substantial. More displacement resulted in lower elapsed times as did high-volume superchargers and fuel pumps. In the final analysis, if you can fill a big cylinder with a huge amount of nitromethane and air, compress it, and ignite it, a massive explosion will push the piston down with ungodly force.

Soon, racers were cracking the main webbings of factory Hemi blocks after just a few runs, and it became apparent that the cast-iron blocks couldn’t manage that much power. (Many collectors of Mopar muscle cars still cringe when they think of the thousands of Hemi engines that were yanked from cars and destroyed by racers in the early ’70s.) So, aftermarket suppliers, beginning with Keith Black, a California race engine builder, began producing strong yet light aluminum blocks and hemispherical cylinder heads.

Rebuilding the engine at least once every few runs became standard. The racers pushed harder. Nitro percentages were increased to nearly 100 percent, larger blowers spun faster, fuel pumps pushed higher volume.

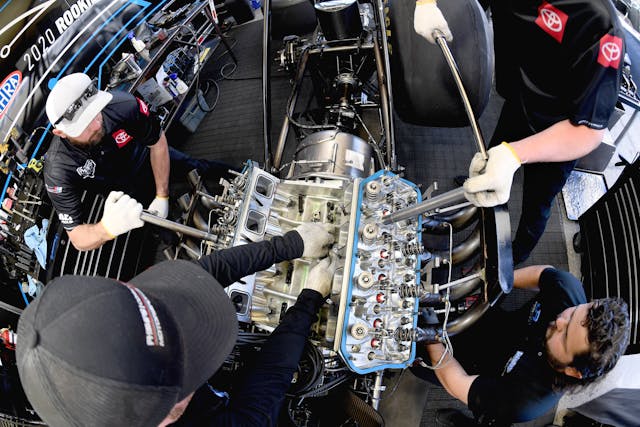

Soon, runs of near 300 mph were causing engine damage regularly. Major teams bolstered pit crews and began repairing engine damage after every run. The best teams learned the only way to be sure that the engine would be in ideal condition for the next run was to rebuild it completely or replace it after every run. Pit crews became teams as well-coordinated as those that play professional sports. Each member was assigned a job to ensure that the engine could be completely rebuilt in the 90 minutes or less that separated each round.

Today’s fuel engines are equipped with fuel pumps that can deliver a fuel mix of 90 percent nitromethane and 10 percent methanol at a rate of up to 115 gallons per minute. At high rpm, the engine will burn more than a gallon of fuel per second. That fuel is delivered to the combustion chambers through 42 injector nozzles. The most common layout includes 10 nozzles in the throttle body or “bug catcher” that sits atop the supercharger and 32 in the intake manifold and cylinder head ports. The modern Roots-type supercharger develops about 60 psi of intake manifold pressure at the finish line. A massive amount of air combined with a huge amount of fuel equates to extremely high cylinder pressure and violent combustion.

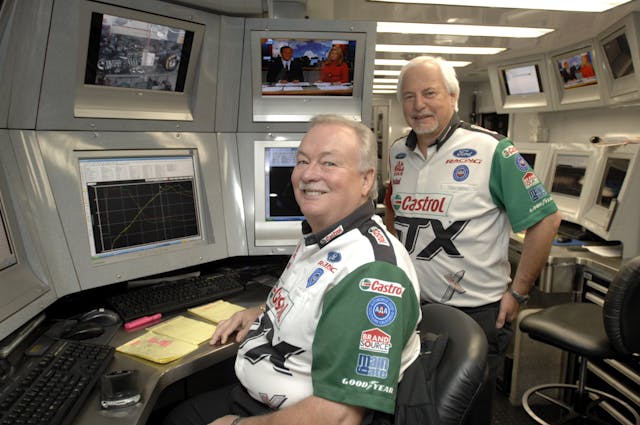

But it’s not haphazard combustion. According to Austin Coil and Bernie Fedderly, who together tuned John Force‘s funny cars to a record ten consecutive NHRA funny car championships, a vast array of hydraulic and mechanical devices control engine parameters during every 4-second run according to a predetermined scheme. The parameters are set for each run based on data gathered during the previous run, prevailing weather conditions, and what is observed on the track. NHRA doesn’t allow computers to control the engine in a feedback loop like those ECUs that regulate street-driven automobiles, but onboard computers can gather data. The typical device monitors up to 32 channels, recording temperature across multiple areas, ignition timing, engine rpm, driveshaft rpm, fuel flow, fuel pressure, clutch actuation pressure, the position of the clutch throw-out bearing, and more.

The engine’s 10,000 horsepower must be delivered incrementally or the car will go up in smoke, so a multi-disc clutch is programmed to engage gradually, with hydraulic actuators and variable centrifugal weights controlling application.

Between rounds, the crew chief analyzes data gathered during the previous run while the crew disassembles the engine. All pistons, rods, rings, and bearings are replaced. The assemblies that are removed will be examined and will go back in the mix if they’re not damaged and have not exceeded their life-cycle limits.

Track temperature and weather conditions are monitored. The brain trust can choose to increase or reduce compression by means of gasket thickness or piston selection. Depending on data indicating how each cylinder was running during the previous pass, the compression ratio of one or more cylinders may be adjusted to a value slightly different than that of the others. The supercharger speed can be increased or decreased. The fuel percentage, fuel delivery curve, and ignition timing curve can be altered. Ignition timing is a key tuning tool, because changing it requires only the insertion of a new chip in the ignition control module.

When the car is reassembled and ready for the next run, it is warmed in the pits to a temperature that will allow it to reach optimum level on the starting line.

On the way to the starting line, monitoring of weather and track temperature continues. Ignition timing chips and components that alter the blower drive ratio are on hand, ready for installation at a moment’s notice. Based on data and whether other cars are having trouble getting traction, the blower speed and clutch timing parameters can be adjusted while waiting in line, the fuel mix can be altered slightly by adding a small amount of methanol or nitromethane to the tank, and the ignition timing chip can be changed at the last possible moment.

At the starting line, a crew member hangs a starter motor on a bracket at the front of the engine. Another tech opens the throttle plates and squirts gasoline into the supercharger. A race official gives the go-ahead, and the starter motor spins the engine, which roars to life. As nitromethane flows into the cylinders the idle becomes crushingly loud.

The starter engine is removed, the body of the dragster is lowered onto the chassis, and the car creeps forward into a puddle of water. The driver, wearing fire-resistant gear and a helmet, is restrained by a seat belt system and a HANS device that limits head movement. The throttle, restricted by a stop, is squeezed, and it opens slightly. The machine’s 17.5-inch-wide rear tires smoke aggressively for a couple of seconds, propelling the machine across the starting line. Well-practiced in backing up while looking forward, the driver reverses to the starting line while a member of the crew directs them so the machine’s tires align with the sticky rubber tracks. Behind the starting line, the dragster’s body is raised, the throttle stop removed, and the idle speed and mixture adjusted one last time. Again, the body is lowered.

The car is staged, the tree goes green, and 10,000 ponies go to work. Even a slight malfunction can cause a devastating explosion, so crew members who didn’t go to the starting line stand ready with new engines, engine parts, a clutch, and even a replacement body.

But if all goes well, the driver will enjoy another bone-crushing sprint to 330 mph. If the win light comes on, the crew will celebrate for a few seconds, sprint back to their pit, and get ready to do it again. They have 90 minutes.

***

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

what is most impressive is in that 4 seconds that engine will only turn around 600 RPM.

So the engine really hardly is turning over in that short tune. It is like a quick burst of energy.

Even after they shut off on a bad run just off the line they will run the quarter mile in 7 sec and cross the lights at at 75 mph. That burst of energy is like a explosion.

You really need to stand up by the line at a race sometime. I got the chance and even over at the fence it is not the same. The Shock wave just about knocks you down as you do more than feel it there.

Few things not specifically pointed out:

1. The block and heads are solid. No water passages on top fuel nitro engines.

2. The engines turn approx 10,000 rpm during the run after cracking throttle open. The direct drive being handled by clutch slipping and controlling rate of application.

3. Just to turn the supercharger takes approx 500 hp.

4. The engines are limited to 500 cu inch displacement.

If you’ve never been to a drag race with the nitro top fuel cars – GO. The incredible noise and feel need to be experienced in person. The sound pressure wave as they go by is unlike anything else.

The nitro class cars are limited to 8500 RPM.

All this focus for a few moments of controlled grenade. About as interesting as the various iterations of 3-liter V-12 Ferrari street cars marketed solely to fund racing which required rebuilds in 30-35,000 miles.

A car that will romp over the open road retaining its engine, clutch, certainly body, for decades is vastly more interesting than disposable momentary thrill you can get for less at a major amusement park or aviator/astronaut centrifuge.

Sure, there is always the personal taste for whatever enthuses your particular internal combustion passion(s). And nobody said Top Fuel and Funny Car drag racing is comparable to street-driven longevity or practicality. Different strokes for different folks, keeps us all happy in one way or another. I say, “what the heck is a Ferrari 3 Liter”? Am I to be ridiculed for not caring about some low production (dare I say, impractical?) European offering that few can relate to?!

In much the same vein, personally, I used to like NASCAR when it was racing modified factory cars that were based on US manufacturers’ hundreds of thousands sold to its loyal customers. Those teams, along with some individual owners/drivers, did their best to gain advantage by trying newly thought of concepts in powertrain, chassis and body tweaks.

These days, you couldn’t pay me enough to watch the current batch of cookie cutter cars, apparently made to conform to that racing entity’s specifications (in an effort to level the playing field?). Dividing a race into several ‘stages’ rather than allowing all-out competition to continue uninterrupted; what’s that all about? NASCAR still has a huge following, and that’s fine for those folks… its just not for me. Maybe I don’t understand the reasoning; hence my ignorance keeps me from enjoying it…

My wife and I have attended several NHRA events around this country and still watch on TV, when possible. Why? Because that’s what WE happen to enjoy. I certainly can’t fault Indy car enthusiasts if they don’t care for this style of racing. I think we, as Americans, all migrate to the things that fulfill something inside us, while we tolerate other’s tastes without condemnation or ridicule.

There is just something about having my eyes stinging from alcohol or nitromethane vapors, the ear-splitting ground-pounding emanation from 12,000 HP vehicles nastily grabbing the track beneath them, and the quick results of these monsters duking it out, round after round! THANK YOU for this article…!!!

“Am I to be ridiculed for not caring about some low production (dare I say, impractical?) European offering that few can relate to?!”

But you do care about a one-off money pit, one-note technological stunt like the above.

Stunt?

Interesting technologically, but still a stunt. But some of us autoholics who like machinery would never subject a car we cared about to drag racing. So one car accelerates incrementally faster than another of a similar type. So what?

But if all that finessing for such a one-note activity excites you, have at it.

You are SO right. I much more enjoy the years of restoration and subsequent driving my vintage vehicles than having a single-use dedicated drag car! Personally, fast acceleration doesn’t trip my trigger when in my own vehicle. I got over that not long after graduation from high school. However, I will definitely continue to HAVE AT IT, as far as NHRA enjoyment is concerned.

After all, it is infinitely more enjoyable than watching football players throwing themselves into piles every minute or so. And those basketball guys constantly running back-and-forth… to me, that is the definition of boring. Why don’t all those guys get jobs and work for their may… oops, I’m starting to sound like…never mind!

Craig Breedlove did 377mph in 4.65 seconds in the 1970’s. But of course his car was powered by rockets!

Standing near the starting line when a top-fuel car leaves is an overwhelming sensory experience. The one aspect you failed to mention is the cloud of unburned nitromethane in the air that burns the eyes an assaults the nostrils. To paraphrase Robert Duvall in Apocalypse Now, I love the smell of nitromethane in the morning, it smells like … HORSEPOWER!

Right. And Breedlove could repeat without replacing most of his car.

He only did 2 runs in a year at most, so apples and cucumbers. Although, I will always like Craig, after his crash in the brine pond, when he said something about almost becoming the first Bonneville competitor, to drown!

It is amazing what they accomplish in that brief moment of time.

It’s truly amazing how much goes on behind the scences, that the fans don’t ever see or even comprehend. What an engineering marvel! I can’t comprehend what all goes through the driver’s mind and body, during those few seconds. Thanks for the great article.

The economics of this are astounding – yet obviously the bills get paid.

it’s called “sponsorship”! So the race-teams pay diddly. Everything’s paid for by the Companies sponsoring these teams.

I used to love drag racing. I practically lived at IRP.

If you go back to the early days of NHRA, all the top speed and low ET records were held by Harley Knuckle Head’s! They were the perfect power to weight ratio, with their over head valves. Of course, the V8s got OHV, and the superchargers, and soon, no motorcycle could beat the fastest cars! But, what a glories time, wish I was there.

imagine how boring this would be to spectators if these gas powered monsters went 100% electric… snoooooooze

amen, brother, amen……….

Electric Motors can have a pretty incredible torque output, but I agree that it wouldn’t get me into the stands. But just think of how happy everyone would be that the Earth was saved from the naughty internal combustion goblins. Why, there would be dancing in the pit area!

No wait… nobody could afford to attend racing events, since much of their income would have gone to fund the subsidies for EV buyers.

I now keep a bag of hot dogs and buns in my car, so when I come across the ubiquitous EV fire I can roast them to perfection and enjoy the meal I can no longer cook on a gas stove.

A few of us got together to watch a national event at Maple Grove. Got rained out the first time but still managed to see a lot of the drivers and crew. I was amazed at how close you could get to these people. Luckily I managed a memorable moment with John Force who greeted fans like they were his best buddies. Returned the following year and got rained out again. A tough pill to swallow for some guys from northern Ontario Canada but a National event is still on my list.

I’m left wondering what the real numbers are. In the first part, it mentions 14 gallons of nitromethane for a 4 second run. That’s 3.5 gallons per second, (or 210 gallons per minute, or 12,600 gallons per hour) at a cost of $630. Later it says the fuel pumps they use can handle up to 115 gallons per minute (do they use two?) Then it says the engines will burn over a gallon per second………..Duh! LOL! Sorry, maybe I’m being too literal here. So what do they actually use?

It would seem to be easy enough to plug those numbers in and calculate the fuel usage, based on Engine RPM and Volumetric Efficiency and Time. However, I find it difficult to NOT accept what a person says, who is intimately involved in the technical aspect of these cars. Yes, the numbers are staggering, but they just demonstrate the incredible achievement of the engineering used to power these magnificent machines!

The 14 gallons used in a single run, includes the burnout and idling on the starting line. Sorry for the misunderstanding.

One of the things that’s amazing to me is that these cars end up going about half the speed of sound at the end. Jist the wind resistance at that point must be measured in tons.

I’ve always felt a little bit funny about funny cars. They are basically top fuel dragsters, but are held back by that silly “body” that adds weight, wind resistance, and requires chassis compromises like having the engine in front. If pure accelleration and speed is your goal, why not lose the restrictions? Maybe it’s the real estate for sponsorship stickers.

It’s a bit surprising just how poor the coefficient of drag is on a top fuel car. Many time it’s been tried to make them more “slippery” but it almost always fails. Common logic says that the added weight of the liner bodies offsets the CD improvement.

Funny cars actually are said to have an improved CD compared to top fuel. It’s likely that the CDa is worse though. It is not uncommon for FC top speeds to match TF top speeds which indicates that they are pretty slick aerodynamically.

Of course, a lot of rules are in place to limit the top speeds. Engine RPM, tire diameter, and gear ratio all are mandated. Speeds creep up very little from year to year, but ET goes down. They just get to the artificially limited top speed quicker.