Strapping my classic to a dyno might have been a bad idea

I have always been curious to put one of my vintage cars on a dynamometer to test how much power it makes. However, such a test never made sense: Most of my cars are stock, with known factory outputs, and the few that are modified aren’t tailored for true performance. Currently, the most promising candidate is my 1965 Corvair: The flat-six under the trunklid sports a mild cam, high-flow air cleaners, upgraded electronic ignition, and a custom exhaust using era-correct headers. On the right day, it really sounds the business.

But … I know where the restrictions are in this engine and what it needs to make big power. The modifications on my car likely haven’t increased horsepower by a significant amount. The epitome of all bark, no bite. So when an acquaintance purchased a house that included a garage with a chassis dynamometer, I wasn’t scrambling for a session. Bad influences—nay, friends—wore me down, and before I could make any excuses about “fragile old car,” the Corvair had a date with a psychic.

That is the role of a dynamometer. It asks your car a few questions, tests its reaction to a challenge, and reveals something about that car based on the test.

First, the challenge had to be set up properly: The Corvair’s drive tires sat between a set of rollers, and straps from ground anchors cinched down the rear from a couple of carefully selected points on the suspension. The front end was doubly secured: a strap and a chock for each wheel.

Then came the hard part: the math.

Before we had started the engine, we had a little problem. The Mustang-brand dyno installed in the my friend’s two-car shop space uses a factor to interpret the data from the load cell. That factor stems from an older metric of “horsepower at 50 mph.” The nerds call it road load coefficient: essentially, it is how much horsepower a vehicle needs to drive down a flat road at 50 mph. Mustang Dynamometer has a handy chart for most models going all the way back to … 1971. No Corvairs built after 1969.

The Corvair’s silhouette—grille-less front end, flat tail—is unlike that of most vehicles in the 1970s. Substitute models weren’t obvious. We looked at the numbers for some cars, averaged a few, and … guessed.

Why sugarcoat it? For me and the Corvair, the numbers really don’t matter. Never did, never will. I was there to learn something new and have a fun afternoon.

We did, of course, have a side bet on whether my little white coupe would crack triple digits to the tire. The over/under figure stemmed from my memory of an old forum post claiming that the Corvair’s factory rating of 140 hp typically came out to around 100 hp at the tire. I was working with a … sort-of known quantity: The engine has been upgraded, but I don’t know its mileage and have no records of who built the engine, or when, or what parts they might have used. I’ve been inside the six enough to trust that it has been rebuilt and that the person who did the job was competent. That said, it’s still a little bit of a shrug as to exactly what is inside.

We entered our factor. Patrick, the owner of the dyno, talked me through the process: Drive up to the chosen gear and hold engine rpm at 3000. Give him a thumbs up, let off the throttle, and allow the engine to coast down to the desired start rpm. Give another thumbs up and, once Patrick returned the signal, mat the throttle.

The noise. The vibration. This subtle sensation of speed—burying my right foot, hearing the engine on song—sat right next to a feeling of calm: The only thing moving was the tachometer needle, which rose with all the speed of an octogenarian filling a buffet plate.

Right as the tachometer needle touched 5000 it was time to lift, put in the clutch, and let the dyno spin down a bit before lightly helping with the final slowdown using the Corvair’s brakes. Letting off the throttle was met with a big pop as flame shot out of the exhaust.

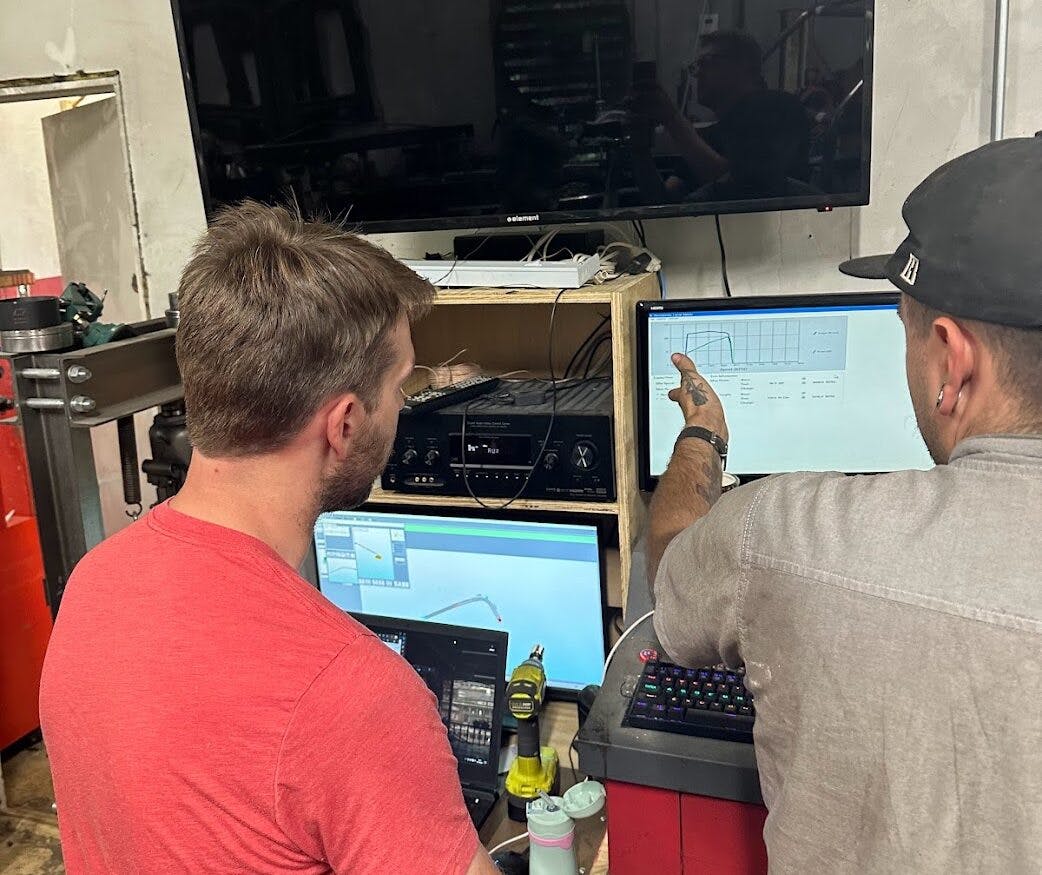

The cacophony of noise, vibration, and anticipation began to mellow. I was immediately proud of the car—nothing had exited the engine except a massive backfire when I closed the throttle. After letting the engine idle for a minute, we shut the car off. I got out, and we surrounded the dusty computer screen to see what the psychic had to say.

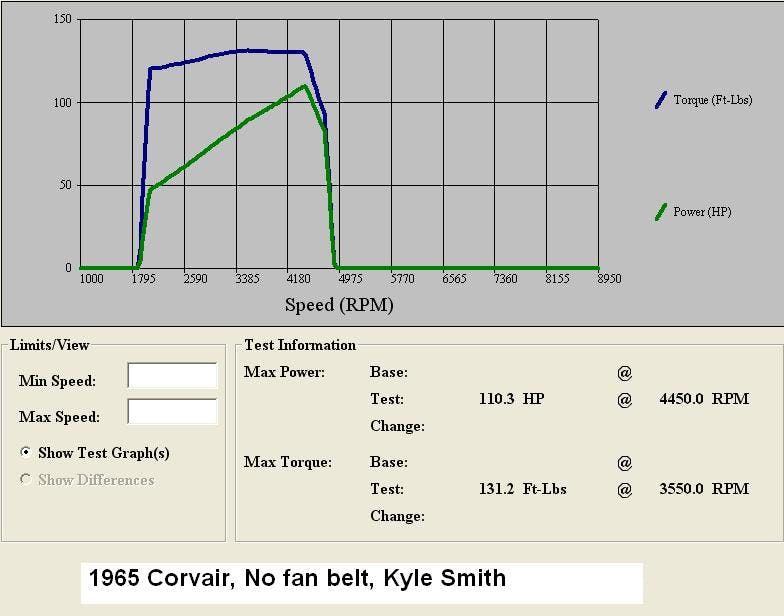

96 horsepower and 120 foot-pounds of torque. Not too shabby. 96 was in the ballpark, given that the original, 140-hp rating for this engine was measured in gross horsepower: The tests were done utilizing an engine, not a chassis, dyno and an engine from which most of the accessory drive had been removed. For the Corvair, the accessory drive is literally just the alternator, but the crank-horsepower figure is optimistic considering that many more components are needed to turn crankshaft rotation into forward motion. The transmission, differential, and other necessary accouterment all soak up a little power. Over the years I have heard drivetrain loss is in the 15 percent range for manual-transmission cars, but that “rule” is misleading at best. It’s hardly a rule, more of a generalization if anything. Being “down” 32 percent compared to the factory rating is actually not bad considering everything that can and should be factored in.

The peanut gallery checked my initial feeling of smug: At higher rpm, a screen of black smoke had poured out of the exhaust pipe—unburned fuel. Confusing, because when I went through and cleaned the carburetors years ago, I could tell there was no funny business inside. Jets were stock sizes, no evidence of machining. While their lack of modifications didn’t explain the smoke, it likely explained why the torque levels off and begins to drive down as rpm increased. What a lovely, flat torque curve.

Since we knew the car wouldn’t explode under the stress of the dyno, we decided to have some fun and take off the fan belt. The Corvair’s is an air-cooled engine: A bi-planar fan belt turns a magnesium fan that forces air down through the finned cylinders and cylinder heads. The system is critical to keeping a Corvair engine alive during regular use, but driving the fan sucks up a ton of horsepower. Your engine doesn’t even have to be air-cooled for you to observe the output difference with and without the fan: Plenty of people with access to dynos have tested flex fans versus electric fans on small-block V-8s.

After letting the big air-mover fans blow down the fan intake for a bit to cool things off as best we could, I popped the spring-loaded belt tensioner in and zip-tied the belt to the oil filter adapter to keep it from catching on the crank pulley during the dyno run. A clean pull felt a good bit spicier and the results revealed all those forum posts from armchair engineers (and real engineers) were pretty well spot-on.

Did I need to know these numbers? Of course not. And if I did, our method would have been a terrible way to discover them. Still, I got the opportunity to test my car in a safe, controlled environment. In just a few hours I learned the Corvair was running rich in the higher rpm range, something I likely would have never learned just driving around town. As I drove home, I thought about how to fix the fueling issues and debated with myself about plopping down the money for a modern cooling fan. Do I need it? No, but I now know what could be, and the prospect sure felt fun.

That psychic inside the dyno computer says the same thing to everyone and is also always right: You can make more power if you want. How much do you want to spend?

***

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

Hate to break it to you but what really counts is how it drives and it’s pretty hard to beat a factory torque curve for drivability. Of course if you need to impress somebody who will never drive your car anyway go for high flow everything, burn tons of fuel, kill drivability with high stall converters, screaming granny gears and pretty much ruin your car.

The 140HP yellow range is 5,200 to 5,500 RPM and the red is 5,500, up to 5,700 why the red line range, I don’t know.

The way your belt included Torque values look, with a leaner high RPM mixture, I think you may have bested 100 hp had you allowed the car to run up to 5252, which is where the torque line and hp line cross, meaning they have the same numerical figure. That’s because HP = Torque x RPM / 5252. (5252 is 33,000 / 2*Pi)

Is that the reason you lifted at 5,000? The Black Smoke? I probably would have too.

I think with a bit of high speed carburetion adjustment to get closer to about .9 lambda, you would have a much better belt attached figure.

Nice Article. I think the best you’ve done for us.

Since my last engine build was a 140 HP Corvair (which I prefer over a turbo), at least you prudent and wound down the motor after the run. Since you don’t know if the valve seats were well staked, you could’ve been rolling the dice to drop a valve seat. That engine rebuild I mentioned occurred after the base engine dropped a valve seat in the classic manner for a 140 – my brother was running hard on the freeway, then entered a cloverleaf exit, let his foot off the gas, and it dropped the seat half-way on the ramp. Now he knows to down-shift rather than “coast and roast”.

Car looks good on the dyno. So can you have some electric motor drive the fan and enjoy the 14hp gain?

It is interesting to note the parasitic loss of the fan. That is a significant number. It would have been interesting to see the head temperatures for each pull. You also robbed yourself of additional Hp delta. As you stopped the test at 4450 rpm w/o the fan vs. 4600 rpm with the fan. I suspect it would be like another 3-4 Hp gain t the 4600 rpm. Based on the torque curve you should have made the pull past 5000 rpm. The aftermarket cam was still making past 4600 rpm. It would have been nice to see the plot of the air fuel ratio relative to the power curve. The power to weight ratio is quite reasonable for a car of the era. Here is my own experience with Dyno Pulls of stock Mustangs. 1969 Boss 302 only change was headers. ignition curve adjusted and slightly richer jet setting. No rev limiter 265 Hp. 1985 GT bone stock no mods 185 Hp. 1990 5.0 timing bumped to 13 from 10 and pulleys, air silencer removed 205 Hp.

I was sure this story was going to include death of an engine, so I’d say yours was a good outcome. 🙂

The 15% generality about drivetrain power loss is a rule-of-thumb for cars of a certain era. I wouldn’t be surprised if 20% is more typical of cars from the ’60s. Modern cars should be under 10%. That said, you didn’t specifically mention that wear from use on your engine probably added some to the figures. Still, I’ll bet you were hoping that the improvements made would have counter-acted that and that you would still be above 100. To get you a little closer, I’d say it would be OK to round up 96.9 to 97. 😁

What/where was the shop that had that dyno? Does your friend who owns the dyno test or tune cars publicly?

A fair story. After reading articles about how setting up a dyno can yield different numbers for the same car, well the numbers can be off. Your test looks like its in the ball park. That said the only numbers that matter to me are 0 – 60MPH. I have two 1966 140HP Corvairs and with the mild Isky 260 cam. Stock carbs and mufflers, bigger air cleaners. The cars run strong, no complaints. Yeah they could be faster, but it wouldn’t make them anymore fun to drive.

I’ve considered fuel injection, but the cost and finding parts in the future are issues. Corvair systems are made up by “garage shops” and future parts and support is questionable. I finally decided, as Kyle, the carburetors are fine and work. If Kyle jetted the carburetors per Bob Helt,s great book, I’ll add that I disagree with Bob’s suggestion to go with bigger jets. I run #51 primaries, #48 secondaries. I’ll admit I haven’t gotten the car hooked up to an air/fuel ratio tester – yet. Note that the “power enrichment valve” can be an issue. Also lazy floats (check the float support spring – they fail). I looked at the newer fan and noted they tend to make more noise (stock fan blades are spaced unevenly to eliminate “siren” effect) and for my stockers aren’t worth the investment. Great read. Enjoy the car.

Being rich wont hurt compared to being lean. Leave it alone, I speak from experience, I will be 70 this September and have wrenched getting paid since 1968 so I’ve seen a bit. Lean melts metal, rich makes the spark plugs black and smokes at wide open throttle. Which would you prefer

On the second and third run the air fuel ratio dipped all the way down into the low 11s. That’s just wasteful rich. I’m fine with being on the safe side rather than peak power, but this is enough extra fuel to cause other problems.

The accessory drive is NOT just the alternator; most of the power is transmitted to the fan, as you later demonstrated. It makes little sense to replace the belt-driven fan with an electric one, as this would just require the alternator to make enough power to drive the fan, which the engine needs 100% of the time. With the engine-driven fan, more RPM (and more generated heat) produces more airflow.

Wait.

No one seemed to noticed the part where the author wrote “So when an acquaintance purchased a house that included a garage with a chassis dynamometer,

How many houses come with a pre-installed dyno in the garage? I have get clearance from the wife on this ASAP. (See honey, they did it. We should too. Just imagine the bump in resale value…)

Exactly. Would I ever come back in the house?

Imagine that! A Chassis Dyno in your garage. I’ve got a soft spot for Corvair’s. Fun article.

No one mentioned the fact that one of the accessories that takes the most horsepower to turn is the alternator. Once the alternator is energized, it puts quite a heavy load on the engine.

I didn’t watch the video, but did he run an additional test w/o the fan belt and using blowers to cool the engine?

I love Corvairs and hate how Ralph Nader and his later falsified tests killed the car.

I owned a 61, and I truly tested the stability of my corvair. I will say the drum brakes left a lot to be desired.

I am in the process of building a 383 stroker for my 64 Chevy and will have it dyno tested. Why? so I will know what I have. After all this work, driving around and wondering doesn’t get it. When I purchased my 2010 Ford Ranger I drove it to the dyno shop and it produced 149 HP at the rear wheels. I like knowing that.

I like that last line, it emotes the old saw about the devil on one shoulder and angel on the other. Love it.