Here is what it takes to get a brand-new engine on a dyno

Dyno tuning is not a new technology, but that doesn’t mean it’s easy. Many TV shows and YouTube stars would like you to think they arrive at 9 a.m. and have big power numbers by noon, but it doesn’t come together that quickly.

What all goes into coaxing whopping power out of an engine? Papadaki Racing walks you through the process in its latest video.

If Papadakis Racing sounds familiar, it’s because previously we talked about Stephan Papadakis’ attempts to make a hero out of the B58 inline-six in the 2020 Supra. His initial teardown of the BMW-derived engine (with the goal of rebuilding the engine and generate four-digit horsepower) gave us a first look inside.

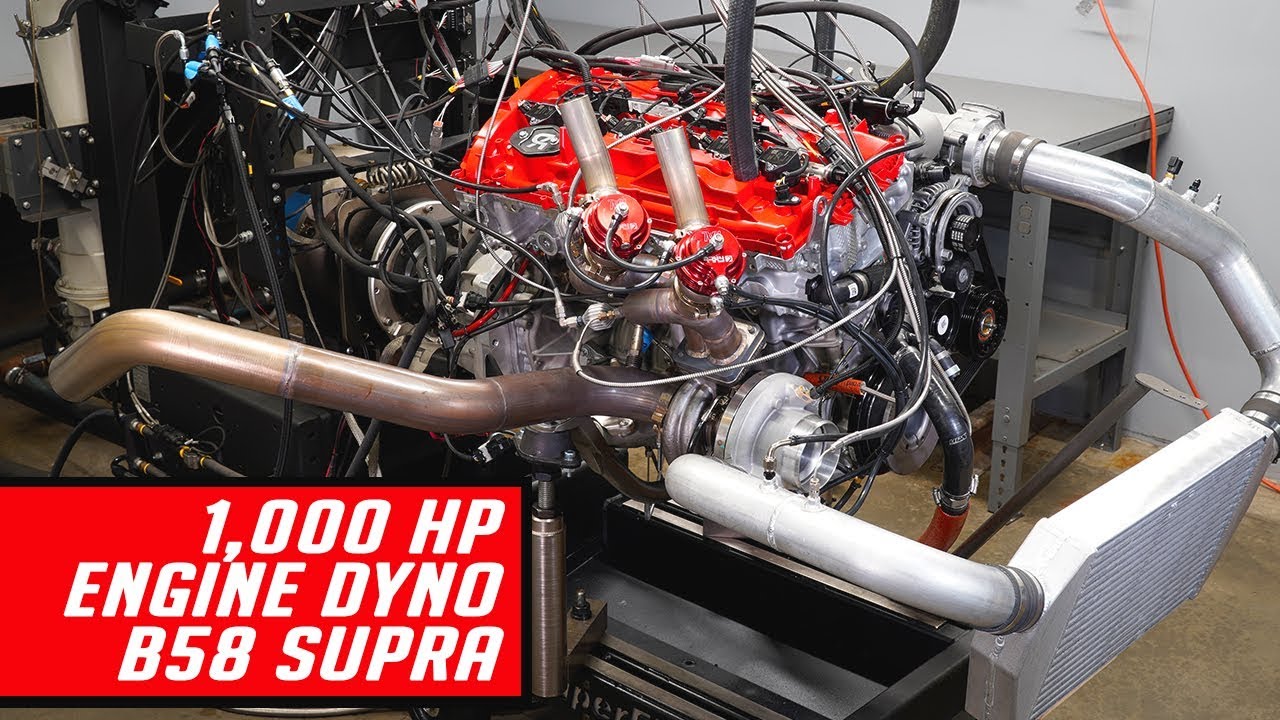

Building an engine to 1000 horsepower is not easy, however. Even the process of testing the final build presents challenges. First, there is the problem of fitting the engine to the dyno, which requires some significant fabrication before the powerplant can leave the Papadakis Racing shop and roll into the dyno cell. With custom bellhousing and clutch adapter in place, a crossmember is fabricated so the engine can sit on a cart, which links the inline-six to the dyno.

Once the engine is in place, the battle begins to wire it so that it will run outside the car’s engine bay. Using an aftermarket ECU paired with factory sensors only complicates matters, to say nothing of the plethora of additional aftermarket parts used in this build. Once that challenge is sorted out, Papadakis and company check the timing before firing up the engine for the first time—upon which they discover an oil leak from the rear main seal.

Running the engine on the dyno while it is leaking oil is a bad idea, so the engine is uncoupled from the dyno and a new rear main seal is installed. The team then runs progressively higher RPM and boost runs, checking the engine over after each run. With the shop floor pleasantly devoid of broken parts and leaked fluids, the dyno is dialed up for the big horsepower tests.

And the team gets oh-so-close to 1000 horses, with multiple runs in the 980–990 range. Even with higher boost pressures, the modern inline-6 engine just doesn’t pick up power. Stumped, the team investigates and discovers that the large fan which refreshes the air in the sealed dyno cell was shut off. With it back on, the next pull handily eclipses four digits, with a final run of 1033 hp.

All told, the endeavour consumes at least three days at the dyno facility, in addition to a few more days that were required to build the parts necessary to hang the engine. A quick clip is catchy and gets people talking, but this serves as a reminder that a lot of time goes into each and every pull on the dyno.