Can You Diagnose this Struggling Pro-Stock Chevy Small-Block?

Whodunits are fun. About a quarter of the top-ranking global podcasts are true-crime-themed. Working to understand every twist and turn to solve the mystery gives people a rush. That’s the feeling gearheads chase when something isn’t working and they want to track down the cause. The engines under our hoods are comprised of myriad parts and systems that, when all operating as designed, create a harmonious symphony of power, heat, and exhaust. When something is wrong, it can be a frustrating experience learning just how much more intricate an engine can be than simple “does it have fuel, air, and spark?”

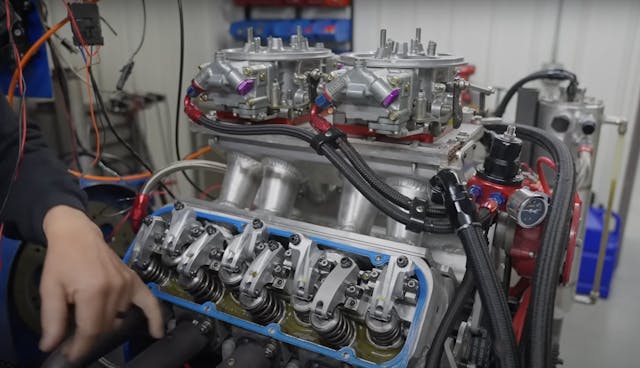

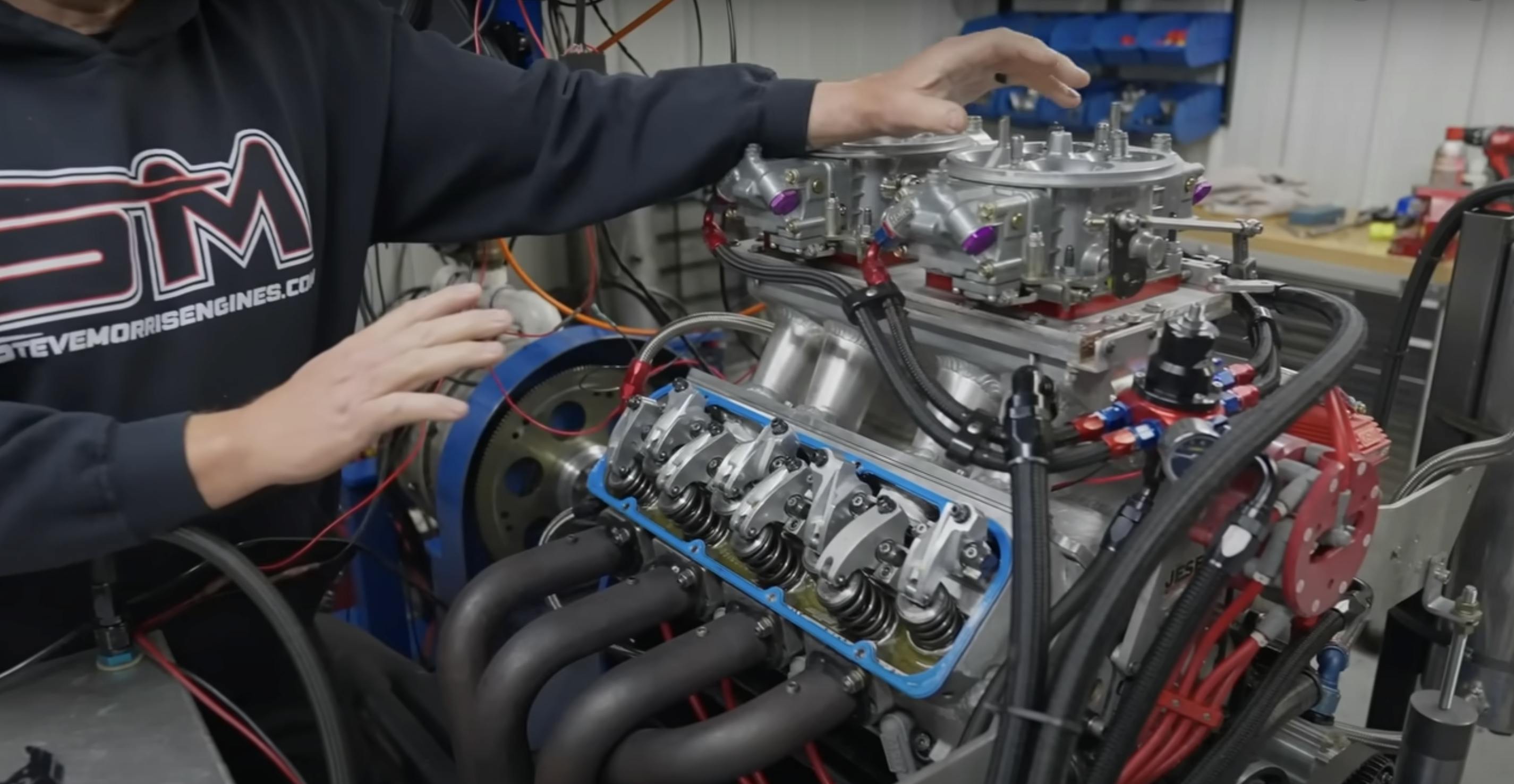

The latest diagnostics tale I’ve been following is that of high-performance engine builder Steve Morris and the small-block Chevrolet V-8 that got bolted up to his dynamometer. The engine is in its second life now; it first served as an NHRA Pro Stock Truck powerplant when the NHRA had such a class nearly 30 years ago. It wears heavily modified Chevrolet casting, which is unique compared with many high-horsepower applications these days that utilize aftermarket and improved castings or, simply, blank-slate billet engine blocks and cylinder heads.

That NHRA class, full of Chevrolet S10- and Ford Ranger-bodied vehicles, is long faded from it’s short-lived popularity. But that didn’t mean this engine was relegated to a shelf or scrap metal pile. Instead, it now lives inside a mini-mod pulling tractor that is designed to move a weighted sled as far and as fast as possible on dirt. It’s a very different use case for the engine, and that created problems. As we learn in Morris’ YouTube video, the first issue was recently solved, but another popped up and it’s a stumper. On the bright side, it’s an interesting reason to learn something.

The initial problem: The engine would destroy the thrust bearing on the crankshaft after only a few runs down the dirt track. Turns out, the amount of clutch usage and pressure plate force over the duration of a tractor pull run is significantly different compared with the rapid-fire hits of shifting down a drag strip. The solution was a roller-style thrust bearing, and to be sure the fix was going to work, Morris hung the engine on the dyno to give it final checks.

After the first loaded pull, the engine exhibited a slightly higher idle than before. After the second pull, the idle reset again to another couple hundred rpm higher. Even after the team dialed in the idle air screws and reset the idle on the carbs, the engine continued to high-idle after a dyno pull. It even coughed a bit of smoke on startup after sitting between pulls. No vacuum leaks could be found.

Later in the video, Morris seems to have some ideas as to the cause of the high idle, but he doesn’t let on much. Can we at-home players suss out the problem?

My personal theory is that the problem is related to ignition timing. The short clip of a dyno pull at the start of the video shows that this engine is using the front-mounted distributor for arcing the plugs. While it’s extremely unlikely to be running a points plate, there could be some form of mechanical advance inside that is hanging up as the engine slows down after a dyno pull. Or the pick-up and sensor are moving due to vibration thus causing a slight timing change.

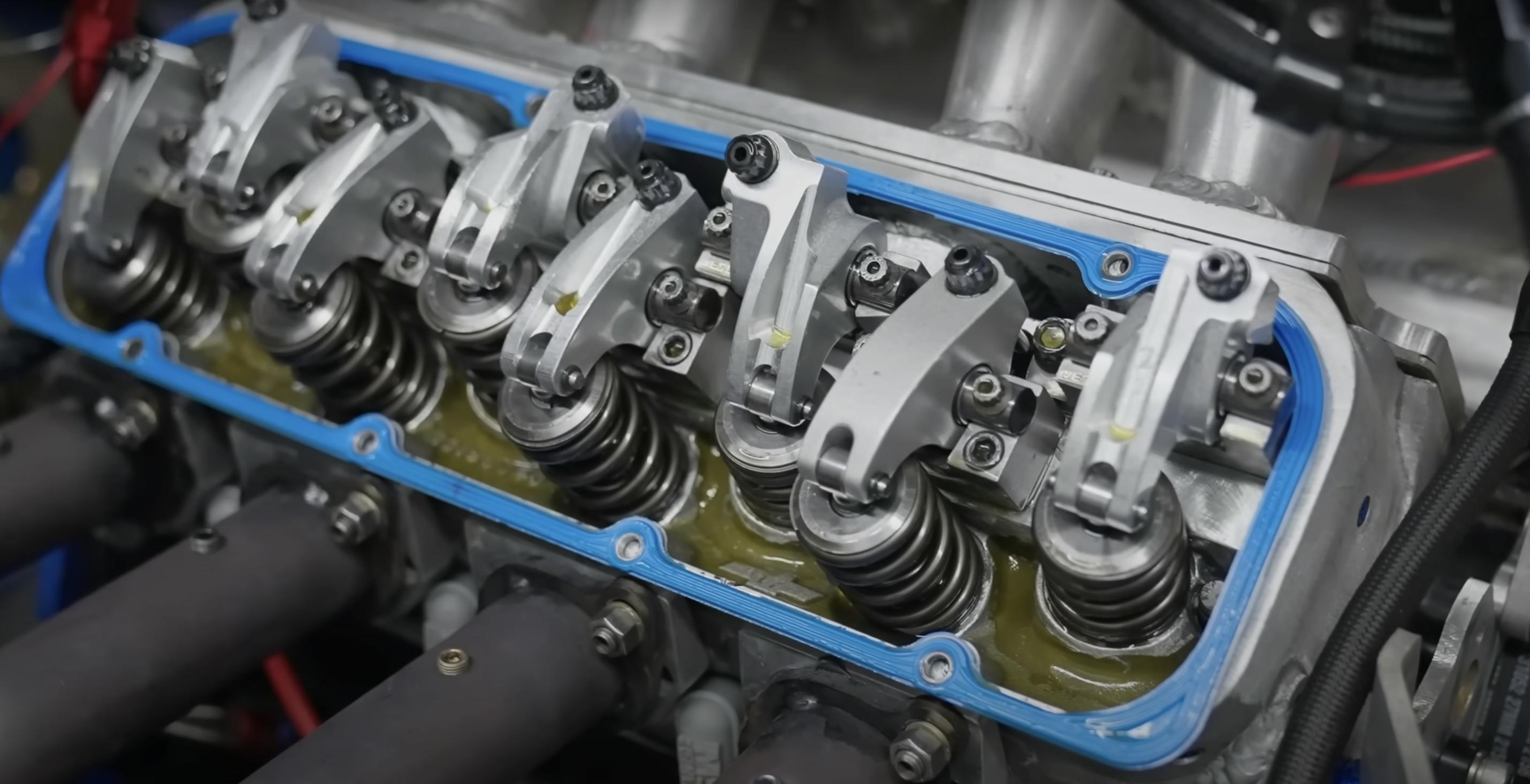

I am also totally aware that my theories could be 100 percent wrong. Is the fact that Morris has the valve cover off in the video a tell or a well-placed red herring?

Morris closes the video with a promise that he will post a video within a couple of days, revealing the answer. These kinds of diagnostic discussions are just plain fun for some gearheads. If you have a solid guess, leave a comment below. I promise not to edit the story when you prove how wrong I am!

***

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

My first thought would be a vacuum leak either around the carbs or the intake manifold. I had the same problem with the 429 ci engine with a metal pan under the intake.??Idle problems and smoke on right turns. But if the intake gaskets were inspected upon removal. You could visually see if they were leaking. Unless they were metal gaskets. My next step would be to check the fuel pressure. Then the timing controller. If the ignition timing was controlled off of the crankshaft damper. I would suspect that the damper ring was moving.

It’s the lack of crankcase ventilation. When the piston draws down on the compression stroke air iinevitibly gets drawn past the rings building pressure in the creankcase. as the pressure builds it continues to draw air through the intake manifold which draws air and fuel through the carburetors. As the crankcase pressure increases, so does the vacuum in the intake maniifold. The crankcsasee can only store so much air under vacuum. This is why the idle creeps up with every pull. The crankcase vent prevents the vacuum increase in the intake. Usually it’s some really cool valve covers that dn’t have provisions or the breathers or PCV system. The engine will also drift down in RPM when you let off the throttle rather than drop of to idle.

Without having done the teardown myself after the crank damage, I’d be curious if the timing set was damaged or misaligned screwing up timing. If it ran fine before it lunched the crank, I’d guess timing, but I also remember early in my career (early 90s) getting the heads and intake aligned could be a pain if the block had and heads were decked and the intake angle was overlooked.

First thing you do is read the plugs.

Isolate which cylinder(s) produced the smoke. Was the smoke blue, black, white, that should lead you to the source of whatever caused the “puff of smoke”. An oddball EGT reading would lead you to the offending cylinder(s), but It doesn’t look like they are reading individual EGT’s as the ports appear to be plugged in the headers, so look at the A/F ratios and see if there is a differential between banks.

Is the issue in a single cylinder, a specific bank, or all cylinders?

There is extra air getting in somewhere that the carbs don’t know about, which is why the idle goes up, and the engine wants more fuel (also why you can close the throttle blades all the way and you now have no control over idle speed. The issue is rapidly progressive and seems to be getting worse with every pull. My suspicion is that the intake gasket could be pulling inward at the bottom letting oil in from the lifter valley.

Possible cause could be over tightening of intake, breaking the intake gasket near or at the corners. Or an intake bolt bottoming out in the head under-compressing the intake gasket with similar results. There are a myriad of things that could cause a vac leak, but the puff of smoke should lead you to it. A compression and leak down test would be helpful to rule out a hard part failure (ie. broken ring or ring land) , but I would suspect if that was the case you’d have constant smoke, not just a puff. More info is key. Keep tightening the circle on the dart board until you hit the bullseye

I’m thinking worn valve seals and or guides. Puff of smoke on start up. Increased idle as it gets hot.

Looks like the carbs are 90 degrees off. Looks like they are facing sideways rather than forward.

I was wondering if anyone checked the fuel pressure from the pump. Maybe producing too much fuel in the carburetor at the wrong time.

Throttle blades are closed and engine wants more fuel tells me vacuum leak. The fact that it blows a little smoke at start up would have to be intake gasket getting sucked in a little more after each pull and idle rpm goes up. Simple check I use is take the vacuum line off the cover start the engine and put your hand over the hole. If you feel vacuum it’s the intake gasket. Had a loose rocker stud do that to me once. Stud was protruding into the intake runner and with it being loose caused the leak.

Is anybody looking at the pictures? This appears to be an SB-2 Chevy with Dry Sump Oiling and a Jessel Timing Belt system with a fixed timing distributer driven off the Jessel Cam Hub. All timing advance is electronically controlled, no mechanical advance. The rocker arms are engineered to be offset due to the Cam Lobe positions in the old-style Chevy block and the fact the SB-2 uses a different valve arrangement:(E-I-E-I-E-I-E-I vs E-I-I-E-E-I-I-E). Stated that a Needle Bearing Thrust was installed to lessen Crank thrust wear brings into question the Rear Main Seal and possible Front Crankshaft Seal in the Jessel setup.

Steve (who I have tremendous respect for) says “throttle blades are closed but it wants more fuel” suggesting vacuum leak but a caption on the video states no leaks found. Unless I missed it he didn’t say he’s verified the timing is stable so that needs to be checked. The wise guy in me wants to rule out an issue with the tach function of the dyno but he’s clearly indicating it’s an engine problem.

as always look at the platform you are working with. get background details, prior performance stats . Listen to the complaint. then perform basic examination.

sooo not having that …all guessing is a crapshoot !

funny that valvetrain toyed with on possibly econo built 30k +motor? {can’t see build sheet !}

offshore motors easily top 100k

this particular engine being for all appearances a sophisticated assembly .,,NOT a “PO BOY” 180 HP station wagon motor .

It should deserving of time and respect proper respect

peripheral analysis could possibly uncover the issue.

that being said a teardown and inspection would be a more deserving route to follow after preliminary inspection to uncover other flaws and failure analysis insight

DO it right or don’t bother.!

Mouse motor: Probably mice. Anybody who has tractors has mice in their equipment.

Air leak

I would pull the distributor out and check the gear on the distributor drive shaft to see if it has worked loose. I’d then, depending on what type of ignition system you have, id then

disassemble the top half of the distributor. If I had another distributor around I would put it in to trial run it. Something has gone south in the ignition system OR something wasn’t assembled properly when you did all of your thrust bearing work.

Do you realize how difficult ti is to read this material when words are broken at the end of a line???