7 fabrication tools that belong in your garage

You’re more likely to replace a part than to repair it, but at some point your DIY journey will require you either to create something from scratch or to modify a piece for the perfect fit. Welcome to basic fabrication. It’s a wonderful thing to practice and become good at. Last week I talked about fabricating a clutch cable for one of my aging Honda motorcycles, and the project made me consider which tools I use on a regular basis to make or customize components. Here are seven fabrication tools that belong in any DIYer’s garage.

Heat

The addition of heat is your best friend when working with most materials. A propane torch will help you to bend metal and supply the power to solder. The next step from this MAPP torch would be a full oxy/acetylene setup, which, for a home shop, falls just below a superpower. It also requires a lot more care to use, but when you can cut, weld, and heat-treat or anneal stock, taking the time to learn the proper techniques is worthwhile.

Big hammer

Brute force is required when making things from scratch. Steel requires percussive persuasion to bend. Multiple types of hammers are best but not everyone has the space or cash for a hammer toolbox in addition to the toolbox for everything else. It’s also overkill for most home shops. Have at least three, though: a big one for moving metal, a medium one for fine-tuning, and a small one for tasks that require high accuracy.

Cardboard

When the delivery truck backs up in your driveway, it’s often the part inside the box that is most exciting. However, those over a certain age probably have a box hanging around their house simply because it’s just a nice box, okay? A sheet of cardboard is a DIYer’s unsung hero. There are few things easier to work with when making templates, protecting surfaces, or sketching a quick drawing to confirm your plans. Cardstock in a large sheet can be a good substitute—it’s easier to store and, since it’s thinner, easier to manipulate—but you’re less likely to have it on hand than an unused box. Why buy when you could repurpose?

Drill

No matter what you are going to make, odds are that the finished product will need at least one hole. While having a drill press is nice, those machines take up bench or floor space—and for most of us, space is at a premium. A hand drill may be as good as it gets. Stack the odds in your favor by having a drill block, center punch, and cutting oil on hand. These will ensure you get nice, squarely drilled holes in just the spot you want without destroying your drill bits.

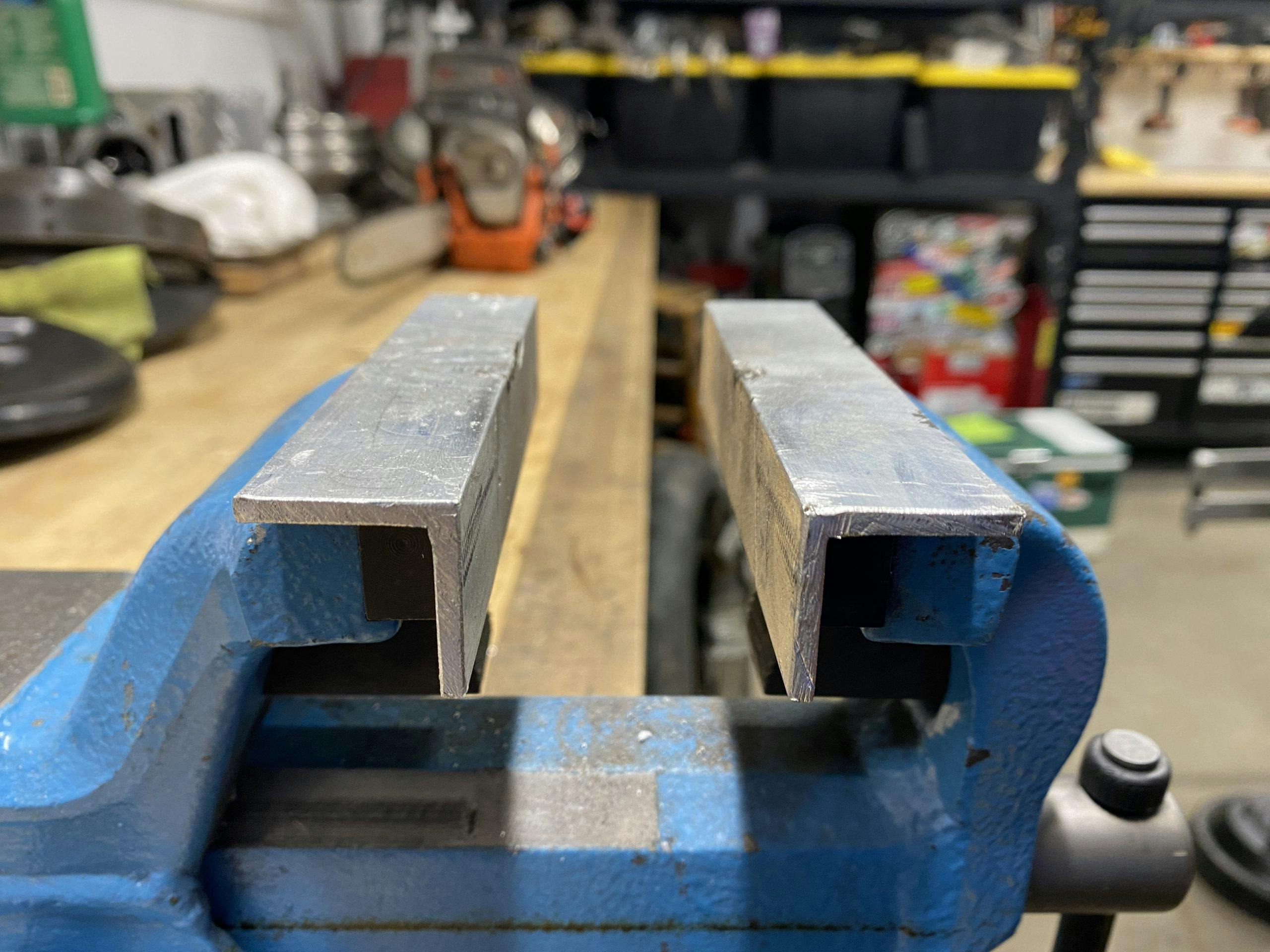

Sturdy vise

While a lot of cool things have been built using nothing but the shop floor and rudimentary tools, a vise is paramount to safe and productive shop time. A good bench vise, properly bolted to your workbench, is also a de facto press and anvil, and can last two lifetimes if maintained. Maintenance is simple: Keep the threaded rod clean of debris and ensure it’s well-greased. Buy once, cry once in the case of this tool: Good vises are pricey, but again, they last.

Files

Big cuts are one thing. Tuning them up or removing small amounts of material from them is another. Between a hacksaw and a file, a dedicated DIYer can create really good-quality brackets or mounts. Files also allow you to clean up OEM or replacement parts for an extra-tidy repair. Grab a couple different sizes and shapes to make sure you can adapt to whatever component crosses the bench. A word of warning, however: Files are made from very hard material, which means they are also very brittle. Be sure to properly store and care for what you buy.

Angle grinder

Nothing beats an angle grinder at serious material removal and clean-up. A 4.5-inch disc grinder provides many options for varying degrees of aggressiveness. With time, discs will accumulate in your toolbox, ranging from a brass wire brush to 36-grit flap wheel.

Safety is paramount with an angle grinder, because things can go sideways extremely fast. Eye and ear protection are absolute minimum but really a face shield, heavy gloves, and an apron are best. Also be aware that a grinder can throw debris across even the largest shops. Either cover up what you don’t want covered in shrapnel, or work in an area where nothing needs to stay clean.

Think something is missing on this list? Tell us about it in the Hagerty Community below.