6 Toolbox Tune-up Tips

A great number of words have been spilt over the years regarding tools and their use. The utility of objects can be amazing at times. Yet even the greatest tool known to man is borderline useless if you can’t find it, it’s broken, or you have to spend more time digging it out from under other things than actually using it. Enter the toolbox. It’s a humble box of drawers and slides that keeps our beloved tools safe from harm or kidnapping.

It’s also typically the last thing any of us think about. The tools inside are critically important but the thing holding them is merely a cabinet to most casual viewers. It is more than that though, and out of respect for one of the hardest-working non-tool objects in the garage here are some toolbox tune-up tips.

Toolbox Tip #1: Empty out and clean every few years

Sometimes it makes sense to have a bunch of seemingly random stuff in your toolbox. Most of the time it doesn’t. Depending on who you are, how you work, and what you work on, it might be smart to go ahead and make the rule that the only thing that lives in your toolbox is. . . tools.

I say this because I am as guilty as anyone when it comes to finding homes for things I don’t need to be keeping. That includes stuffing any number of trinkets and doo-dads into my toolbox. All of those things inevitably get in the way when I am trying to actually work. As a hobbyist and not a professional mechanic this small amount of time doesn’t amount to much time lost, but dealing with minor inconveniences can stack up and sap some of the joy out of working on your projects.

Toolbox Tip #2: Lube the drawer slides

This only takes a minute with a can of aerosol lubricant to make sure your drawers continue to work like new for years to come. We ask drawers to carry a lot of weight and older slides can use the help to make sure they are not sticking or grinding chunks of dirt or debris into the delicate parts. Extend the slides out fully, blow them off with canned air or an air nozzle, then give them a light spray with a silicone or dry-film lubricant. Grease or oil-based lubes will likely just attract dust so be careful what you grab out of the chemical cabinet.

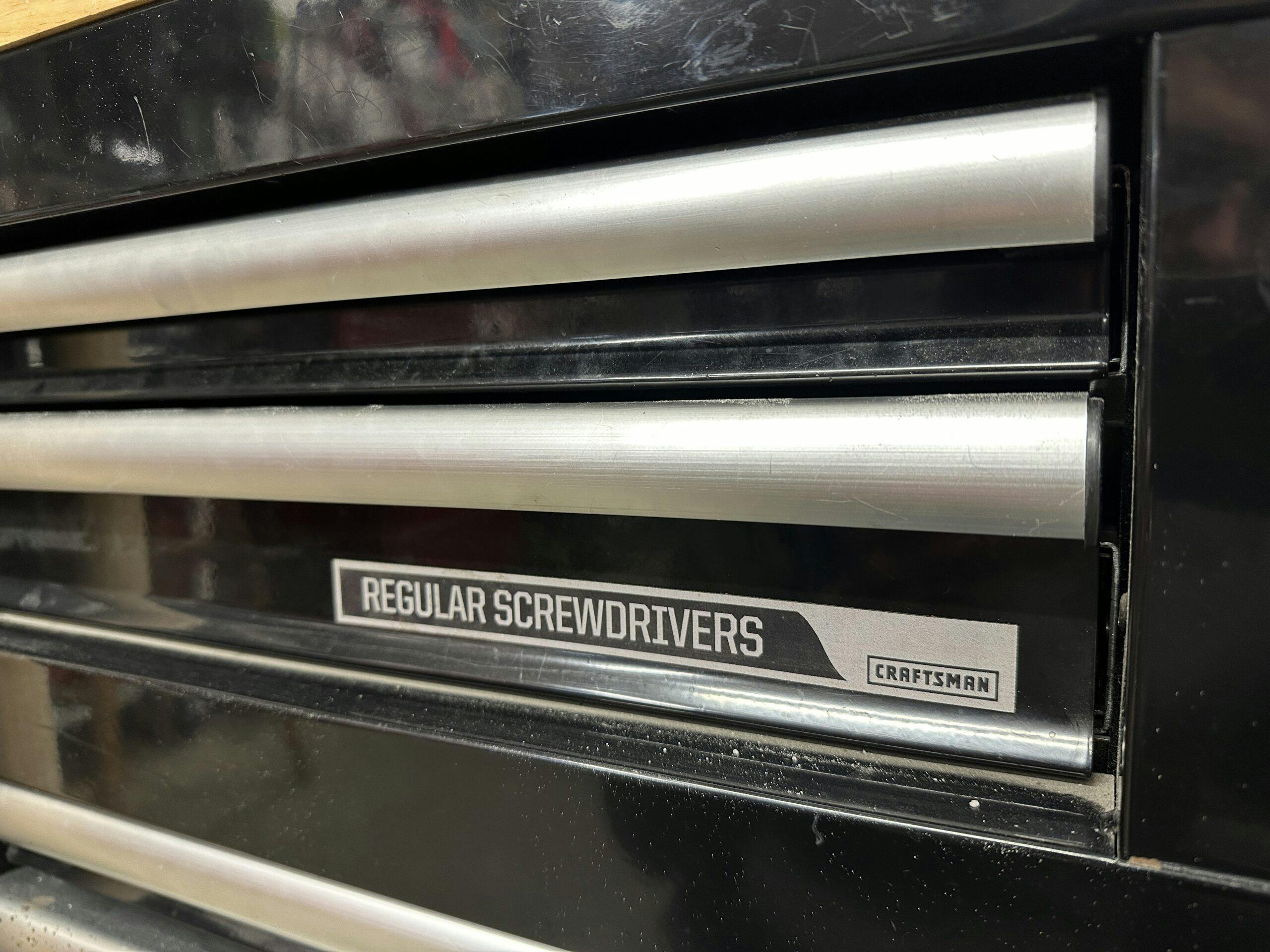

Toolbox Tip #3: Label the drawers

Most of us have kept everything in the same place for decades but that doesn’t mean it wouldn’t be nice to have reminders from time to time of where that thing you are looking for is. I’ve personally also found that sometimes the brain gets to thinking about something and that one-track mind forgets other tool options I might have that could do a job better. That whole out-of-sight, out-of-mind thing can cost you sometimes.

Labels also allow helpers to assist more easily—both in getting and returning tools. Who doesn’t like the thought of their helper actually assisting with cleanup? If they know where things go, it won’t be just a pile on top of the box.

Toolbox Tip #4: Add power for a charging drawer

We are getting a little luxurious here but stay with us. Battery tools are more popular than ever, and that means chargers are cluttering up our workspace. With a little planning, it is often possible to snake a short extension cord into a drawer via the side or back, which allows the charger to hide inside. Kits featuring motion-rated cables and outlets exist and can be had for reasonable money considering the space they can free up in and around your toolbox. Of course, always monitor charging batteries to lower fire risk.

Toolbox Tip #5: Keep (or make) it mobile

Nothing is more annoying than working on a project that only fits on the other side of your workspace from where your tools are. A rolling cart is a good option, but the ability to roll your entire toolset right to where you need it can be extremely nice. Adding wheels to a toolbox you already own might get clunky, but it is often worth it. Just be sure to use casters appropriate for the weight of a toolbox. Most toolboxes come with wheels but it is always tempting to build or stash them into a corner. Keeping the ability to move your toolbox allows for easily creating ideal working conditions or at least allowing easy reorganization and cleaning of your space.

Toolbox Tip #6: Let it evolve

It’s cool to still have the same box after decades in the garage, but don’t let nostalgia cloud your sanity. What lives where inside or even the toolbox itself is not sacred and replacing or reorganizing can greatly benefit your functionality and productivity. Switching to a larger box that allows better access to the tools you use most elevates your working experience more than most other tool investments. After all, regardless of which tool you are reaching for it is likely inside your toolbox. Before you can use any tools, you have to use your toolbox.

***

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

We all seem to have the same disease: putting decals and stickers on our toolboxes. Does anyone know where/when/why this started?

I would imagine the first sticker was put on a toolbox the day after the first parts supplier started including them in orders!

Well they had to go somewhere, I do not want them plastered on my favorite ride.

I knew I was in trouble when I realized the stickers are worth more than the toolbox.

😄

And like some bumpers, a few of mine are more or less held together by the stickers.

The stickers on the box(s) ARE worth more in memories than the boxes.

Teenage skateboarder,Teenage racer,AirForce,post AF,cars,motorcycles,cars again. Car shows,races,cruises,clubs. Drag racing,Autocross,road racing (cars and bikes) vintage racing…its all there. Every one a snapshot in an ever evolving enthusiast life. Moving a box that has been against a wall too long brings forth another happy memory of past friends,some lost,some drifted away,memories of good times over come the struggles of the past.

I will never sell an old tool box.

I love I have my grandfathers tools,and my dads. I still uses them and they are in there boxes,no stickers,ever.

I never did. Even when I was 14 years old and had my first toolbox I thought it made them look like a kid owned it.

Agreed.

I too have my tool box from high school. My daughter uses it now.

Kansas City screen printer Forest Gill had some war-surplus self adhesive paper and a dream in 1946. I guess that original bumpersticker just couldn’t keep itself off of the toolbox.

Well-laid, old man. Some enterprising feature writer is working up an archeology article now.

Like bossa nova tapes for the pre-Beatles years, show cars should have age-appropriate stickers. My ’63 Stude has a Goldwater bumper sticker because of course it does.

I used to stick the appropriate stickers on the underside of the hood and trunk lid, but these insulated hood blankets stopped that notion. Toolbox, here we come!

I got a magnetic Moulin Rouge momento a friend brought back from a trip to Paris

I bought a new Craftsman double decker rolling toolbox back on Black Friday 2008 for 100 bucks . Looking at the prices of them now it’s like I stole that mother !

I also bought a craftsman box for $100 and also years ago a box from a friend’s departed dad for $50. That one had many irreplaceable decals on it worth more than the box!

I bought my last brand new boxes around 2000 when I was working as a mechanic at an amusement park and I spent about $400 for everything, I have seen similar setups are over $1,000 today. That job taught me that I needed a box for long term storage of less used tools and a “gig bag” for the basic every day jobs. I used to lock the gig bag in the flip bin of my box. That gig bag sees a lot of action to this day now that I am in my oil change, brake job, and tune-up years.

I generally avoid the clean out with the keep it organized. If you put things back where it came from then it stays clean and then you do not label.

Yes these boxes have wheels but they are not always mobile. Depending on your space, the floor condition, the size of the box and how top heavy it is can make a difference.

You have to use care as some boxes can easily move but most can tip easy or even roll into a car if you fail to lock the wheels.

The best thing is to use large boxes for the tools and then get tool trays on wheels or even a small tool cart. Get one that is stable and easier to move.

I have 3 large boxes and two smaller rollers. I use the trays to move them near my work project.

As for stickers the Summit Stickers on the front are good for 15 HP and on the side only 10 HP LOL!

I did mine up with a yellow Pratt and Miller Racing Jake Skull in the lid on the black boxes. It looks cool but uncluttered. My old decals are on my old red Mac and a cabinet I have.

I just warn on the box moving as too often I have seen people tip them and destroy a box by trying to get more mobile than it is.

Exactly. Heck, I’ve even seen a tech pushing his smaller cart, hit a crack in the concrete and tip over. Luckily there was only a few dents and dings and no injuries. But imagine a 5 or 8 ft long box?

Yes the wheels are to move them when needed not always to where you are working.

You need a good level floor to move them easily.

I took off the casters and mounted my tool chests in place — which also serve as a single long workbench. However, the best thing I bought, not realizing how much I would like it, is my teardown table. It has a drawer & shelf on the bottom and that has become my “rolling toolbox”. Put what I need in there and go. Why move the timing light, ring compressor, sanding blocks, brake tools, air tools, etc when I only need some wrenches & screwdrivers, maybe a couple of specialty tools, and one air tool?

PS: My decals? Engine hoist and Fridge. Nothing on my tool boxes or tool cabinets!

I started out with a small Craftsman base and four drawer topper many years ago. I was lucky enough to get my hands on a couple of scrapped bank cash drawers that are about waist high. They are deep enough to store bulky power tools and the like. Between the classic tool box and the cash drawers, I’ve got plenty of storage for my hobbyist tool collection.

Tool chest sticker “Run the elite out of town”? Not appropriate for Hagerty web site

Why’s that? Because Hagerty should have something against athletic shoes? Looks like it has a Nike swoosh. Might you explain its inappropriateness to us uniformed, please and thanks?

That is a Nike promotional bumper sticker from the early 2000s. It was meant to encourage amateur runners to take the local road races and push themselves against the (typically out-of-towner) professional or elite runners that come in to those races as ringers. Of course, everything is open to interpretation, so I cannot say you are wrong in how you read it. I’ll consider how some of the things I rarely notice a little more moving forward. Thanks for your comment.

Or maybe you can just “consider” the over-sensitivity of some folks who want to read something into darned-near anything and everything – and then just brush it off.

Being offended is competitive sport these days

10-4

Being competitive is unacceptable to many these days. Everything needs to be equitable…same outcome

Oh Gawd, this just keeps getting worse!

Thought it had to with an old Lotus.

I thought it was for a 1974 Ford that looks a lot like a Torino.

I thought it referred to getting a Lotus to run.

Well played 😀

Only if you are a Liberty loving American.

lighten up Francis…

aka-psycho(good one)

As Psycho would say……….. any of you guys touch me or my stuff, and I`ll kill ya. Classic line.

He doesn’t say “guys”. You would have to look it up or rewatch for what is actually said…

Agreed – someone’s not looking closely or has a teeny tiny agenda

Lighten up.

Yea— Looking at that toolbox & the background I’d say whoever owns it is part of the Elite—

As a general contractor, I have a decent collection of tools as well as various building materials and paints etc. I have a newer rule concerning storage of materials. When I place items on the shelves I tag it with a date. If 1 year rolls around, I check it out and see if I am going to use it on a current or upcoming project. I then rotate the tag 90 degrees and add where it will be used. If it doesn’t have a current or future use, it goes away, either by selling it, donating/ trading or trashing it, or if it is a NIB, it return it to the store.

Exactly

A large 2 or three bank box, or one of those tall tool chests may have casters, but they are for the initial placement or if you relocate to another bay or even shop. They make carts with a few drawers and a top area that you place a typical set of sockets, wrenches, drivers etc., and if you are going to need a certain tool for a job, then you pick that out of the larger storage box and roll the smaller cart to te project and get to work. Or, if you only have one of those carts that is basically flat self on top and maybe has another shelf below, you load up the tools you’ll need and throw the parts on there and get to pushing.

Don’t worry Curtis, my father is a television repairman. He has this ultimate set or tools. I can fix it.

Is this some sort of movie quote? I don’t recognize it. If it’s not, I’m really confused as to how it relates to the story or other comments! 🤔

Fast Times at Ridgemont High- a classic. This was Sean Penn’s line after crashing the Camaro.

Ridgemont High reference, that’s funny right there!

Ah, thanks! Been a looonnnggg time since I watched that one, I guess (either that, or the memory banks are failing faster than I thought).

Toolbox Tip #7 – actually pick up all the tools from the various stashes around the shop and the back of the truck and put them IN the toolbox. That one I struggle with

I have my set from when I used to be a mechanic, and my dad’s set from when he retired from being a machine adjuster at the other end of the shop, so box portability is not really an issue in my garage. The mobile toolbox is my truck

Man, that gets me, too. Lots of the time, I’m eager to use/install/present-to-wife/whatever the thing I’ve been working on, and so I grab it up and leave the tools where I was using them (my fingerprints in not-yet-dried-paint will testify to this). Then I have to either make myself go back and clean/put them away. Otherwise, they are STILL there the next time I start something else. I’ve called myself all kind of names for leaving things out (most of them learned from my dad when I was borrowing his things), but it just seems to be a lesson I never completely learn.

Don’t use silicone spary in your shop if you plant to paint anything. Unless you like the look of fisheyes in your finish.

Good point since it will updoubtedly also get on the tools inside the drawers.

A Matco dealer gave me a tip back in the 80’s when I bought my first real box. I pull all the drawers out and lube the slides with Vaseline. 40 years later I still do it and they just glide. I’m sure everyone has their thing.

I made the mistake of using a spray lube that coagulates into a light grease (no, not WD). It’s great for door hinges, not so much for drawer slides. They’re practically glued shut now. Out they will come once again, now that I have a few good suggestions of what to use instead!

Absolutely. Maybe we can’t say the brand?

I hate that stuff more that rust.

I have a small can for 4-wheeling to get water out of a distributor cap, but have never needed to use it.

Separate your tools by use. My (primarily) automotive tools live in my (allegedly) roll-around box, except for the tools I carry in my 51 year old daily driver for roadside repairs–on my or a friend’s car. My woodworking tools live in drawers and shelves (old kitchen base cabinets) under my workbench, and “house-fixing” tools (pipe wrenches and other plumbing tools, circuit testers and other household electrical stuff) live in another set of cabinets salvaged from our kitchen remodel. And yes, they’re all labeled.

What? Pipe wrenches aren’t allowed in the mechanics box for working on cars? I’ve been doing it wrong all these years?

And don’t open more than about 1/3 of the drawers at one time. If over half the weight is in those open drawers, the box will tip over on you.

Enjoyed this read, hits you right at home. I made major changes to my pole barn/shop this past summer and one of them was (along with a serious deep clean and crap jettison) was changing how I used my tool boxes. With multiple cars both cherished classics and daily drivers, and junk that runs but I cant seem to get rid of, I finally took my “rolling base box”, placed my “top box” on top and presto! I have all the primary mechanic tools you need that can NOW be rolled to the car, eliminating a lot of steps back and forth. And this reminded me, labeling is on the list this summer. Happy New Year!

Another tip: If at all possible/feasible, gravitate to drawer organizers in your toolbox. I have ones for sockets, end wrenches, and screwdrivers. I just wish my pliers drawer was taller so I can get one of those organizers that allow me to stand pliers/cutters/etc. on their side.

I learned the hard way to make sure the wheels are still bolted tight to the bottom box after several years of being in the same place.. Moving my bottom and top box after many years at the same dealership to start at another one, a wheel fell off when pushing it out and the loaded boxes went horizontal.. the top box hit on the corner of the lid… a dent but worked as it should after that.. Good old Craftsman purchased new in 1968

The move was from a Midwest BMC dealership to an East Coast dealership… a 100% Snap on area, when they saw my Craftsman box roll in, they wanted to know where I had been working on tractors.

Yeah, thanks for the nice welcome guys.

I still have all my original Craftsman tools as well, only a very few of them required exchange with the 100% warranty program.

The guys who were all Snap On likely still have debt that makes student loans look like pocket change.

Nothing against Snap On, they make fine tools. But I still maintain Craftsmen as a better value in 90% of the cases. I have Snap On in the remaining 10% for things Craftsmen didn’t offer, like 6 point deep well impact sockets. Bought those in about 1980 off the truck, took two months to pay them off but still in my top box (same vintage Craftsman). The 1/2″ and 9/16″ have been replaced due to 40+ years of wear.