Want an F1 car? BAC builds the next best thing—road-legal, too

Welcome to Small But Mighty, a short series about boutique British car companies. You may not know much about Ariel, Briggs, Caterham, or Morgan, but you probably see at least one car the way they do: as a crafted thing, meant for enjoying and possessed of its own personality. To read more about the landscape of this cottage-car industry, click here.

Though motor racing is a global business, Britain is justifiably proud of its place at the center of it. An oft-repeated adage is that from a single hill in Oxfordshire you can see the headquarters of six of the 10 teams competing in Formula 1.

Several hours to the north, in an otherwise nondescript industrial estate on the banks of the River Mersey and next to Liverpool John Lennon Airport, is one firm trying to condense England’s proud F1 legacy into a car on which you can hang a license plate.

With a single open seat mounted at the center of what looks like a slithering cybernetic cobra, the BAC Mono is perhaps the ultimate hedonistic toy.

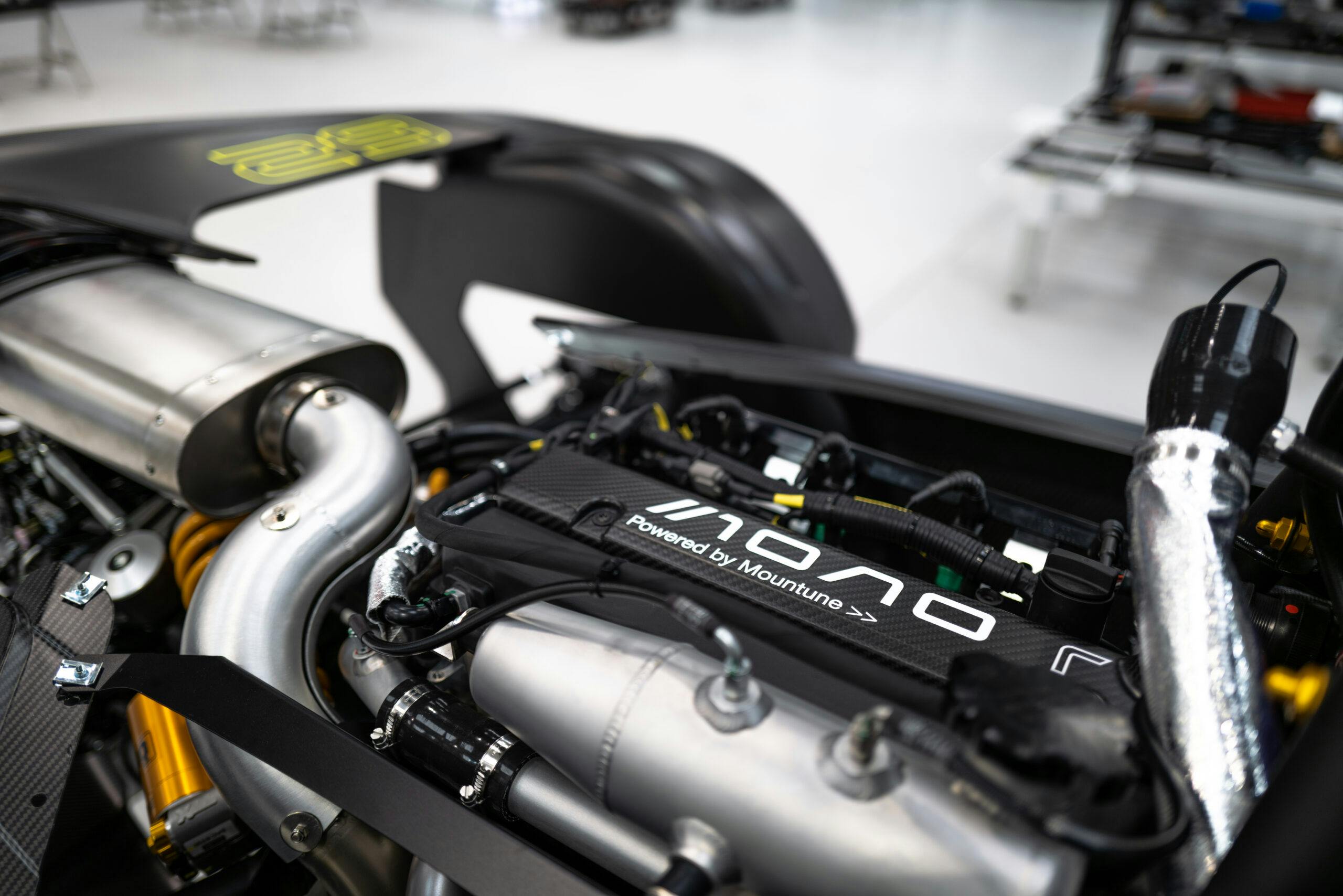

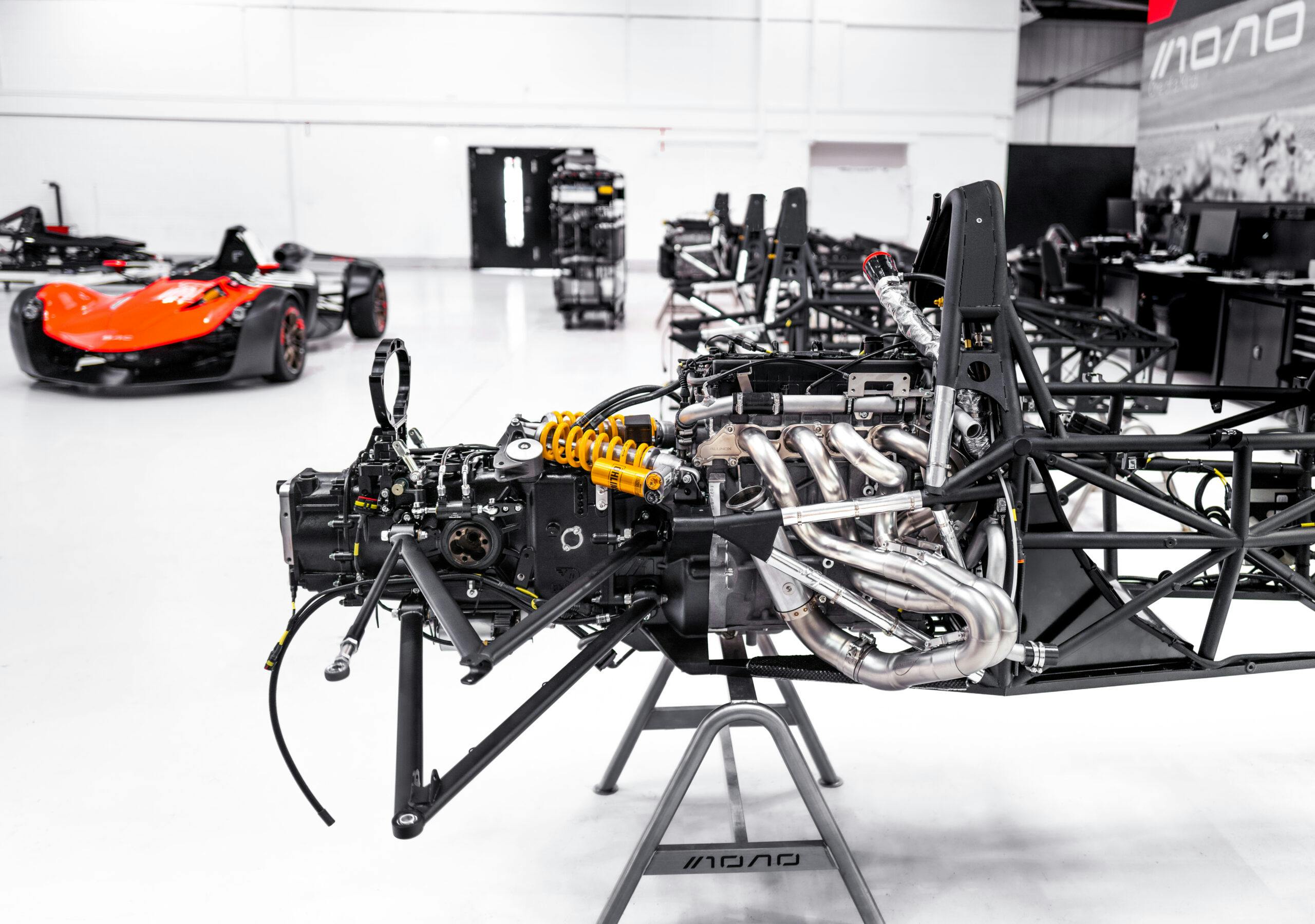

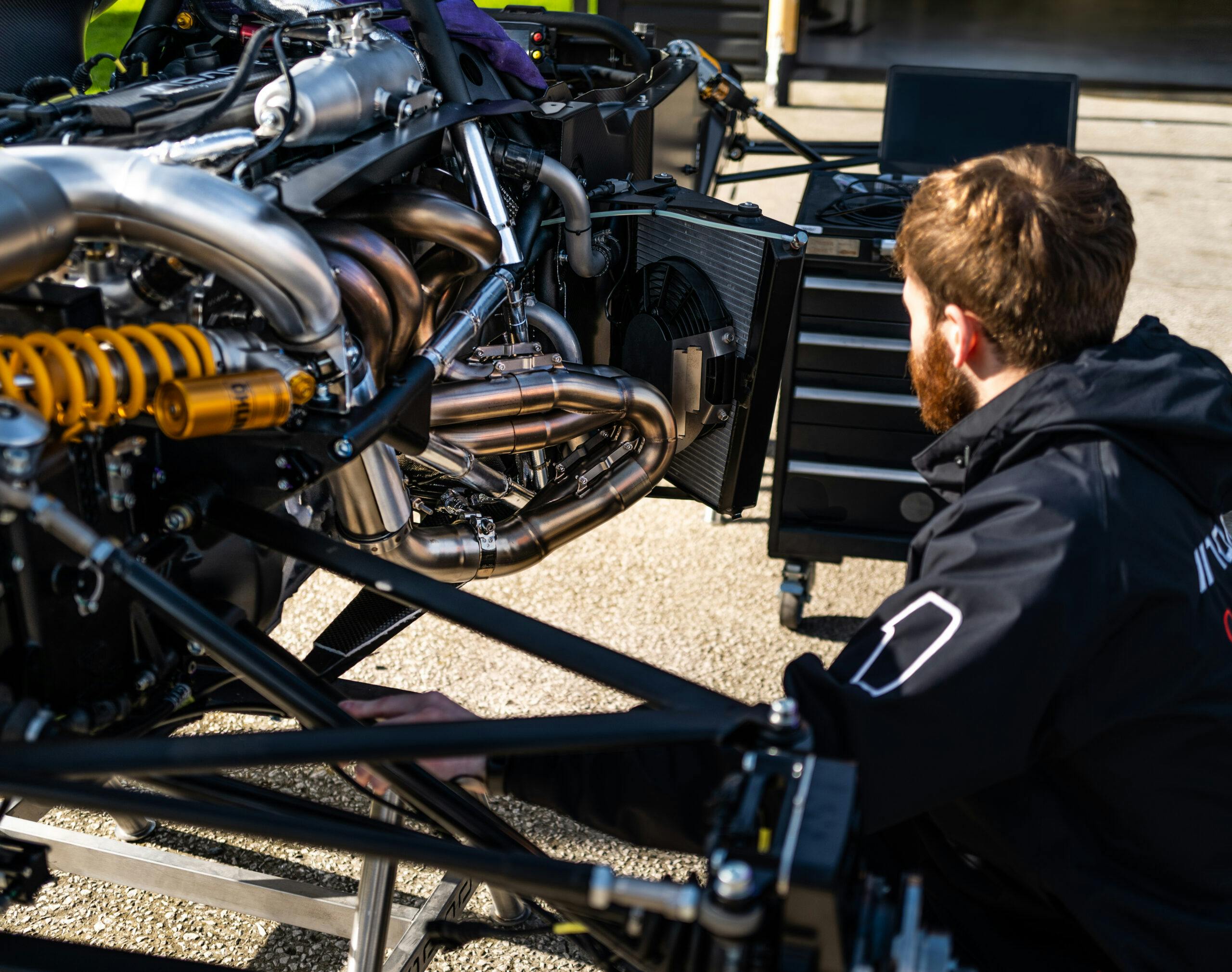

It’s effectively your own private formula car, complete with tomorrow-tech carbon graphene and exotic niobium-alloy components, inboard dampers peeking through slits in the bodywork, a 332-hp Ford-based turbo four-cylinder attached to a paddle-shifted Hewland sequential six-speed from F3 racing that is also a stressed member of the chassis, and no hint of bumpers. And no doubts about the car’s purpose as the ultimate F1 simulator for armchair Verstappens—plus any others with around $200,000 to spend on the conviction that Porsches and Ferraris are bloated and floaty.

Briggs Automotive Company, or BAC, is the brainchild of brothers Ian and Neill Briggs, a car designer and a car engineer who grew up locally, going to the nearby Oulton Park circuit and the local forest rallies. In 1995, the pair set up a vehicle design consultancy in Germany that did quite well, helping Ford launch its RS performance brand among other projects.

Success led a few years later to “I guess you could say a midlife crisis of sorts,” says Neill Briggs. “Right from the word ‘go,’ it was a vehicle with a singularity of purpose, which was driving pleasure and performance.”

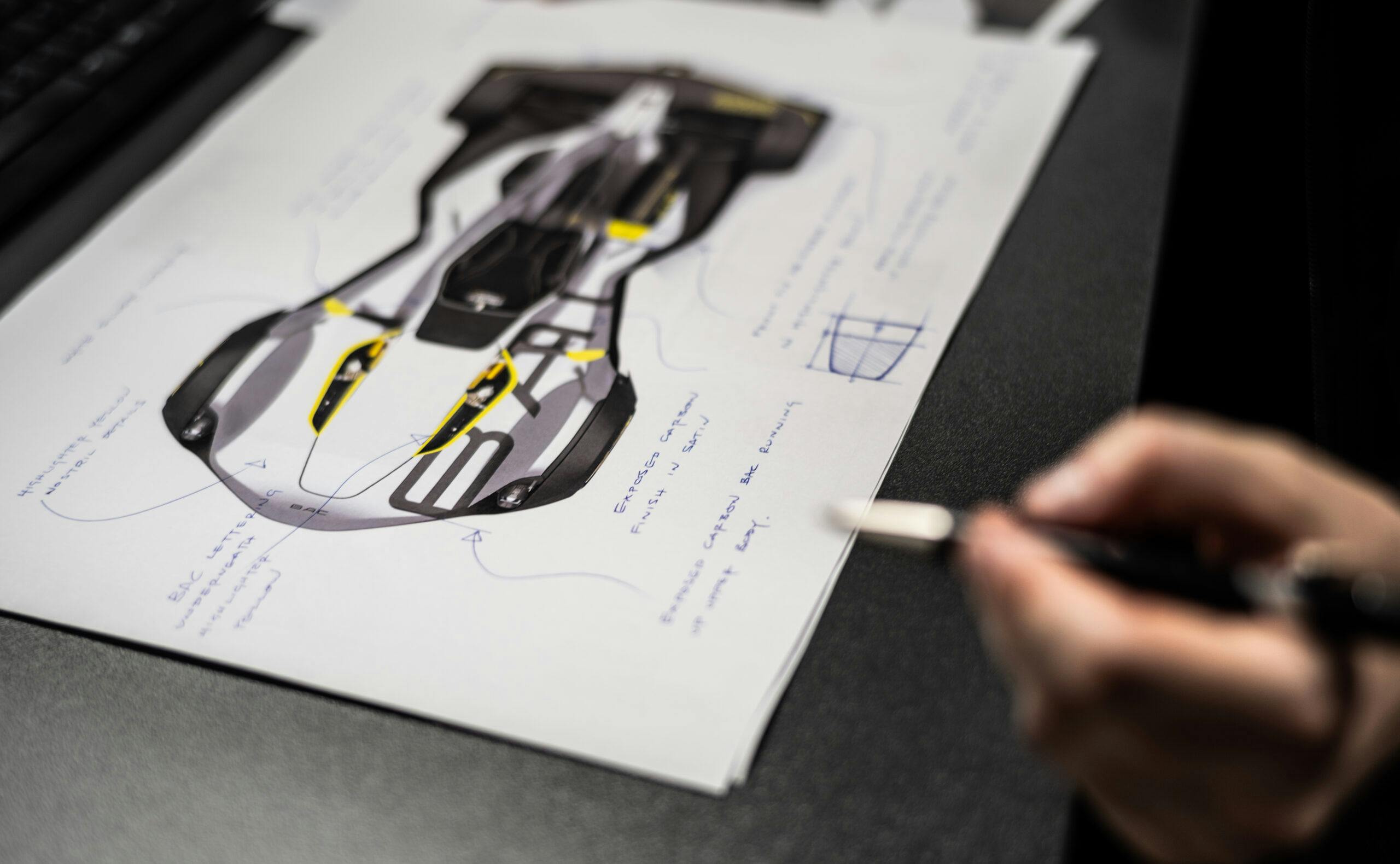

The steel tube-frame Mono started as the product of a 2008 design competition for a unique luxury sports car within the brothers’ consultancy, and by 2009, BAC was incorporated as a separate company with its own staff.

“Now it consumes 120 percent of our time,” says Neill, and the consultancy has fallen away. Money was exchanged for the first production Mono in 2011, and since then, the 50-person company has delivered around 150 units, 30 of them to the U.S., all titled for road use.

Behind the glass-walled showroom and delivery center, the Mono and even lighter and racier Mono R take shape in a 7000-square-foot production facility in which the cars circle around the workshop from station to station, exiting at the rate of 2.5 per month. The company claims 95 percent of the parts come from the U.K., about 50 percent from the region surrounding Liverpool. Personalization was always central to the Mono’s pitch, and BAC has worked up an online design program that helps customers envision their own color and trim schemes using various storyboards that are retro, racing-themed, or futuristic.

Just as in racing, constant iteration defines the Mono, the brothers keen to work in new ideas and technologies as they come along. The car’s forward composite crash structure has been redesigned nine times (it includes a small trunk), and 3D printing has recently been incorporated for items like the headlight buckets, freeing BAC to shape the headlights to their own design rather than work around an off-the-shelf part or spend millions to tool a bespoke injection-molded bucket. A two-seater is on the drawing board, and the company has conceived a hydrogen fuel-cell design study called the e-Mono as a glimpse of a potential future.

A few customers are asking about an electric version, says Neill, but “what the power unit is for that vehicle is quite a complicated question.” Loading such a small, light car with the batteries necessary for a decent range and performance will ruin its character, he says. “When you start to add 150 kilos [330 pounds] to a car that weighs 500 kilos [1100 pounds] that has quite a big knock-on effect.”

Says Neill: “The niche vehicle sector relies on an existing supply chain, which doesn’t exist yet in the EV space.”

***

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

This article first appeared in Hagerty Drivers Club magazine. Click here to subscribe and join the club.

Another great article Aaron! I love this car.

Ever since I saw it in a TV ad. A few years ago one passed me on the 405 near Santa Monica. The hydrogen two seater sounds intriguing!