Rochester Ramjet fuel injection altered the automotive landscape in 1957

In the mid-20th century, fuel injection was still largely the stuff of fantasies. Then General Motors shocked the automobile world and put injected Chevies and Pontiacs on the showroom floor. Car-loving performance enthusiasts drooled, and the Beach Boys sang about a “fuel-injected engine sittin’ under my hood.” It was automotive culture shock. We were accustomed to seeing that technology on race cars, but fuel-injected cars that you and I could drive? That was other-worldly.

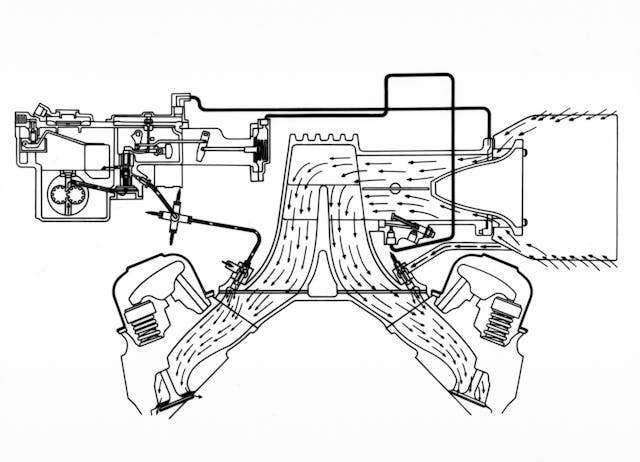

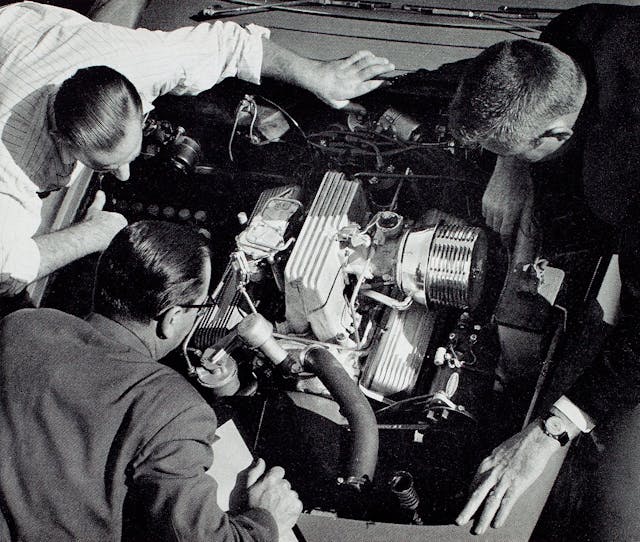

Although the Rochester Ramjet fuel-injection system that premiered in 1957 on Corvettes, full-size Chevrolets, and Pontiacs moved musicians to song, it wasn’t long before it had mechanics tearing their hair out, and, on occasion, replacing the pricey injection system with a carburetor or three. Although Rochester FI is relatively simple in concept and includes only three main components—an air meter, a fuel meter, and a manifold—it is a unique design rife with hidden complexities, multiple versions, a long parts list, and an abundance of pitfalls for even skilled mechanics.

Today, fuel-injected GM cars of the era are rare and expensive collectibles. A quality restoration of any of these mid-century classics must include the rebuilding and tuning of the fuel-injection system. While a knowledgeable DIY mechanic might attempt the job, most will want to farm it out to a skilled tech in order to get the fuel-injection system functioning as it should. No matter who does the job, it’s best that the car’s owner understands how the system works.

Fuel-injection—pressurized fuel delivered via nozzles and a pump—made its debut on 19th-century diesel engines. During World War II, injection systems fueled aircraft engines. Postwar, Mercedes-Benz had implemented a timed injection system on its 1953 300SL, which borrowed largely from diesel systems. But the technology was still foreign to most American buyers when GM introduced it.

At its heart, the Rochester system is constant-flow fuel injection, not unlike the fuel-injection systems manufactured by Hilborn and others that drag racers have used for more than 70 years. Like those systems, it constantly delivers fuel under pressure to nozzles in the intake runners.

The Hilborn system uses a return line in the fuel system to send some fuel back to the tank and thereby regulate mixture. An orifice or “jet” in the return line determines how much fuel will be returned, allowing only a specific amount to be delivered to the nozzles. Because dragsters operate almost exclusively at wide open throttle, mixture can be regulated by that single jet. A simple valve attached to the throttle linkage controls fuel delivery at idle. But these “on or off” fuel delivery systems are undrivable on the street.

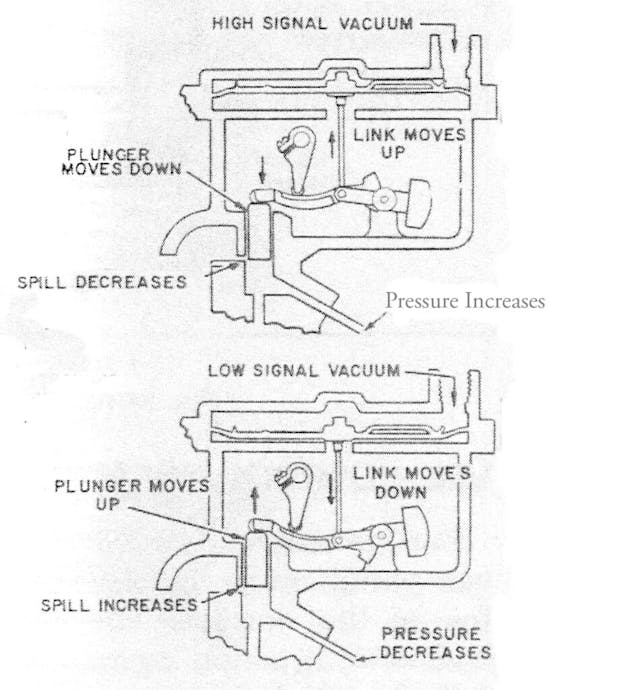

The Rochester system also utilizes a return line to regulate mixture, but rather than controlling return-line flow with a single orifice, the Rochester uses a moving valve or “spill plunger” that opens and closes a spill port to the return line in proportion to the needs of the engine at various throttle openings and load conditions.

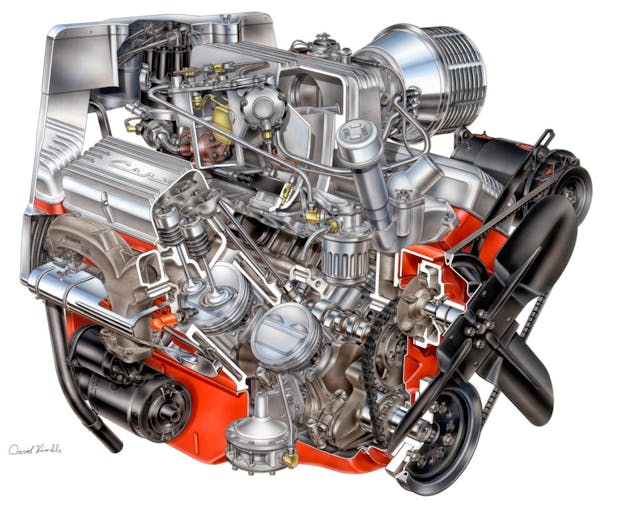

A conventional mechanical fuel pump delivers fuel to a reservoir at the base of the fuel meter. A float system, like that of a carburetor, regulates fuel level in the reservoir. A gear pump in the reservoir is driven at half engine speed by the ignition distributor and delivers pressurized fuel to the fuel meter.

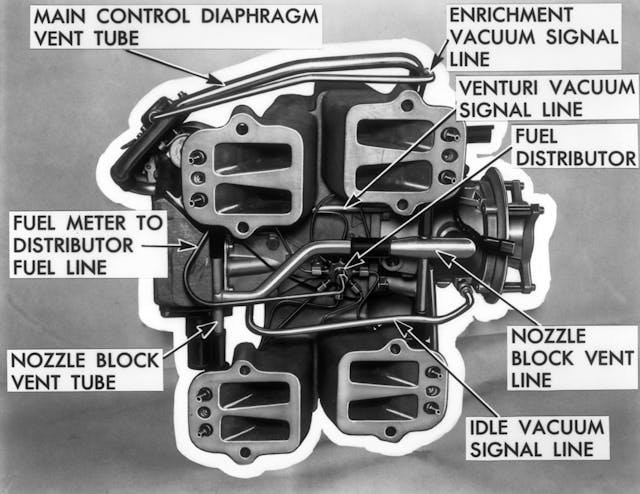

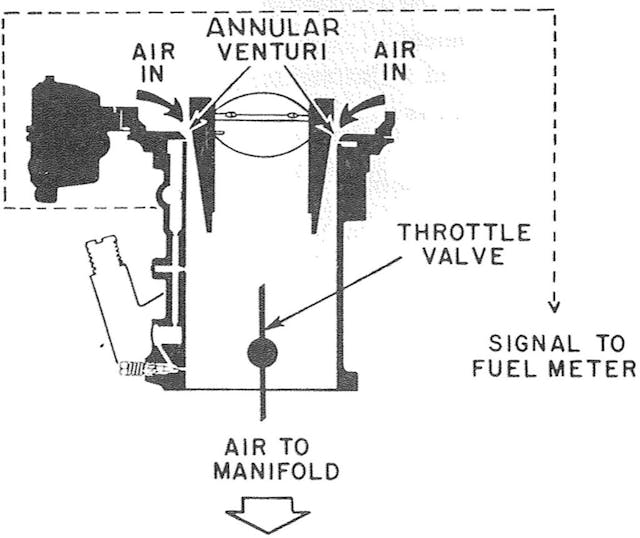

The system determines engine fuel requirements by measuring vacuum at two locations—in the intake manifold and at a venturi in the air intake. The vacuum levels sensed at the intake venturi and manifold determine how much fuel should be delivered to the spider fuel distributor, directed to eight fuel lines, and injected into the intake ports by eight nozzles, one above each intake port.

Vacuum at each location is measured by a diaphragm. A relatively small enrichment diaphragm measures the strong manifold vacuum signal, and a large diaphragm measures the weaker venturi signal. The venturi vacuum signal is a direct measure of air flowing into the engine at any throttle position above idle. The venturi vacuum diaphragm is linked to a fuel control lever. That lever is in contact with the spill plunger and moves it up and down, opening and closing the return line spill port and regulating the amount of fuel delivered to the nozzles. How much force the fuel control lever can exert on the spill plunger at any given time is determined by manifold vacuum.

Manifold vacuum, which varies in respect to throttle opening and load, acts on the smaller enrichment diaphragm, which actuates an enrichment control lever. (The enrichment control lever is called the ratio lever in early GM documents.) When the enrichment control lever changes position, it alters the pivot point of the fuel control lever, thereby varying the amount of force that is applied to the spill plunger. That, in turn, determines how far the plunger moves and how much of the return line spill port is exposed.

The enrichment control lever is where adjustments are made to fine-tune the air-fuel ratio. Rich and lean stops limit the movement of the lever. The lean stop determines fuel mixture at cruising speed with moderate throttle opening and high manifold vacuum. The rich stop comes into play at wide open throttle, when manifold vacuum is reduced. Both stops must be set accurately to achieve good performance.

The above covers only the basics. Supporting systems, like cold-start and cranking detection are important as well, and their function varies by model year and even system part number. Anyone attempting a restoration must come to battle heavily armed with knowledge and documents.

Jack Podel, of South Bend, Indiana, is among the few highly skilled techs who still specialize in Rochester FI. Podel notes that he doesn’t rebuild fuel-injection systems; he restores them to like-new condition. He says that many skilled DIY mechanics try to repair the system, but a lot of them end up shipping their failed attempts to him. Part of the problem, he says, is that most systems have been repaired in the past, often incorrectly or with the wrong parts. So, when you disassemble the unit, you can’t be sure that what you see is what GM intended. While the system was produced for only nine model years, from 1957 to 1965, 20 different part numbers were assigned. Podel says that among them, he counts 16 significantly different systems. And though all systems are conceptually straightforward, each includes hundreds of small parts, all of which are subject to deterioration over time, and many of which are specific to one model year.

John DeGregory, a Pennsylvania-based tech who is also a highly respected restorer of Rochester FI systems, offers a bit more encouragement to DIY fuel injection techs, but he says anyone attempting the job must be educated or they’ll do some damage. Both Podel and DeGregory will assist those who have problems over the phone, and each offers a wide range of replacement parts.

If you’re going to try to do it yourself, you’ll need a factory manual and some secondary references. Because the systems have so many differences, your primary source should be the appropriate GM manual. Reproductions of most can be purchased inexpensively online. But the factory manuals are best supplemented with the advice of experienced techs. A good secondary source, like Jerry Bramlett’s Ramjets that Run! can be very helpful as well. Bramlett was a leading Rochester FI tech for many years but is now retired.

Parts are available from a few providers who still doggedly deal in the restoration of these systems. Among them are Podel, DeGregory, and Jim Neuffer. All are listed below. It’s recommended that parts be purchased from an expert source—that’s the best way to be reasonably sure you’re getting the right part.

Rochester Ramjet fuel injection was a milestone achievement for the U.S. auto industry, and the injected GM cars that have survived are esteemed classics. Restoring one of these automobiles correctly is both an obligation and an honor.

Rochester Ramjet Parts and Service

John Podel: (574) 232-6430

John DeGregory: (724) 832-3786

Jim Neuffer (Parts Only): (585) 637-9562, 11 a.m. to 11 p.m. ET

***

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

Great article!