When Cars Attack: Cautionary Tales from The Hack Mechanic

As I’m not wrenching much this winter (a situation caused by not really having a proper winter project, as well as using that as an opportunity to give my nagging back injury a chance to heal), I thought I’d write about the spectrum of wounds, cautionary tactics, near misses, and emergency room visits that the decades of wrenching have produced. Considering the amount of wrenching I’ve done over the past 45 years, I’ve had surprisingly few serious injuries—no ambulances have visited my house. But there has been blood and one near catastrophe.

Cautionary Tactics

Racers talk about losing their judgement when the red mist (adrenaline) flows and they begin doing things they know they shouldn’t do. When you’re removing some stuck bolt or recalcitrant component, it’s easy to get influenced by “mechanic’s red mist” and go all Cole Trickle on it (“This part is goin’ DOWN!”). Because of both impaired judgement and the larger forces at play when you’re pushing or pulling hard, this is when you’re likely to hurt yourself. For example, when gripping on a wrench or a ratchet handle and pushing it to loosen a bolt, if the ratchet slips or the bolt breaks, it’s the back of your hand that’s likely to smack against something sharp or pointy. The tendons back there are very close to the surface; you can plainly see them whenever you flex your fingers. Pushing a wrench or ratchet with the open palm of your hand instead of the closed fist can make the difference between a few stitches versus surgery and months of physical therapy.

Helicoptering up a bit, it’s good to be in the habit of approaching any repair with a degree of situational awareness. What are the hazards in the area you’re about to stick your hands into? Are there jagged edges? Hot hoses? Frayed wires or ends of cables that can cause a painful puncture that gets infected? Are there rotating parts you need to be aware of? Is the thing that you’re removing going to drop down and pin your hand? Simply taking a moment and scoping this stuff out is time well spent.

The phrase “gas and spark” is often used to describe the necessary precursors for an internal combustion engine to run, but it’s also a cautionary phrase, as you really don’t want these things combined outside of the engine’s combustion chamber. Spilled or leaking gas can easily be ignited by a stray spark from either an electrical connection being made or broken, or cutting something with a spinning wheel. So don’t, for example, use a Dremel tool to cut a metal clamp off a fuel hose.

But that’s all small stuff. In my opinion, the most serious vector for automotive injuries is jacking up a car and working under it. I believe I’ve told the story on these pages about how my physics professor for my sophomore mechanics class (and part of mechanics is statics—the study of the forces on things that aren’t moving) was killed when his car fell on him, forever imprinting on me that intelligence and common sense don’t necessarily go hand in hand. To be fair, I don’t know the details of what went wrong, but ever since that event, I’ve “double-jacked” cars. That is, if you’re going to crawl under a car, be sure to put it on a hard level surface (concrete, not asphalt, and definitely not hot asphalt), jack it up, position the jack stands, let it down onto the stands, and then leave the floor jack in place as a backup.

Near-Misses

There are five that stand out.

The lift incident: By far the scariest thing that ever happened to me while fixing cars was the time my mid-rise lift nearly killed me. A chain of three unlikely events—the design of the lift that makes it possible to defeat the safety latch (the thing that supports the weight of the car mechanically instead of relying on the hydraulic pressure in the cylinders), my having flipped that latch and not flipped it back into the auto-lock position, and, while I was under the car, my legs having accidentally kicked one of the car’s removed wheels, by pure chance sending it rolling into the lift’s pressure release lever—caused the hydraulics to depressurize and the lift to slowly drop while I was under it. Fortunately, I was under the back of the car, and due to it coming to a stop on its brake drums, there was enough space that my chest cavity didn’t get crushed. (You can read the details in the link above.)

At the time, I was stoic about it and simply finished the repair, but with hindsight, I could’ve been killed, and I’d be lying if I said that that didn’t rattle me. Obviously I no longer move the latch from its auto-lock position, and I’m assiduously careful to make certain that, when a car is on the lift, the lift is resting on one of the stops and not on hydraulic pressure.

The jack incident: While not nearly as serious as the lift incident, the jack incident viscerally demonstrated the importance of jack safety. On a hot late-summer day, I drove down to Cape Cod to have a look at a BMW 5 Series wagon. I met the seller in a CVS parking lot. I noticed that the lot was asphalt and had a very slight grade but didn’t think too much of it. I’d brought a medium-sized aluminum floor jack to check for front-end play, so I slid it under the nose of the car, found the jack point under the subframe, and gave it a few pumps to get the front wheels high enough to wiggle. As I was checking the first wheel, the seller said, “Look out, look out, LOOK OUT!” The combination of the jack sinking into the hot, malleable asphalt and the slight grade caused the car to topple off the jack and toward me. I was never in real danger—I was wiggling the wheel with no part of me under the car—but it alarmed both of us. Whenever I think about swapping a wheel with a car supported by only a jack, I remember this incident, and reconsider.

The wiper linkage that pinned my wrist: Decades ago, I was troubleshooting the non-functional windshield wipers on my BMW 3.0CSi. Doing so required me to pull the multi-prong plug off the wiper motor, turn the key to the accessories setting, switch on the wipers, and check for voltage and ground at the connector using a multimeter. When I was done, I pushed the connector back onto the wiper motor, which rewarded my efforts by suddenly springing to life. When it spun, it rotated the wiper linkage, which pinned my wrist against the piece of metal that the wiper motor mounts to. I’ve recreated the event in the photo below, which was instructive because the way I remembered it, it was the act of reaching in and plugging the connector back in that put my wrist in a position where it could’ve gotten pinned, but now I see that that’s highly unlikely. Regardless of exactly how it happened, my wrist was pinned, and the motor was still on.

The incident occurred in the late 1980s when my wife and I were still living at my mother’s house in Brighton. I stood there, watching my hand turn white as the unrelenting torque of the wiper motor cut off the blood flow and stood a good chance at slicing open my wrist, but because the garage was on street level and the house was a flight up from the sidewalk and my wife’s and my apartment was up on the third floor, my calls for help went unanswered. Fortunately, while looking around the engine compartment, I saw a wrench within reach, and I was able to use it to undo the negative battery cable, which killed the power to the wiper motor. Even with the power cut, though, it took quite a bit of wiggling to extricate my hand, and when I did, the crease on my wrist looked like a dull guillotine blade had bounced off it.

The vise that attacked my foot: I was installing a new exhaust in my car, replacing every piece except the catalytic converter. Unfortunately, one of the bolts holding the cat to the resonator was frozen in the flange and needed to be drilled out. At the time I didn’t own a drill press, so I put the cat in my car, changed into summer clothes, drove into work, and used the drill press there. I clamped the flange into a vise that sat on the flat surface of the drill-press table. The vise wasn’t secured to the table, though; it was free to move, allowing you to line up the drill bit with its target.

Drilling out a bolt is slow work, I got impatient, the mechanic’s red mist got the best of me, and I leaned a little harder on the drill press lever. I saw a little whisp of smoke, heard a little chirp from the bit, and then the bit grabbed the flange, causing both the catalytic converter and the vise to rotate and throw themselves on the floor. They landed about six inches from my left foot. As I looked down, I saw that I was wearing sandals. IDIOT!

Emergency Room Visits

It’s the two head wounds that rise above the background of hand stitches and metal filings and rust removed from my eye. Head wounds, of course, generate a lot of blood, making them very dramatic. And these two incidents were just so stupid.

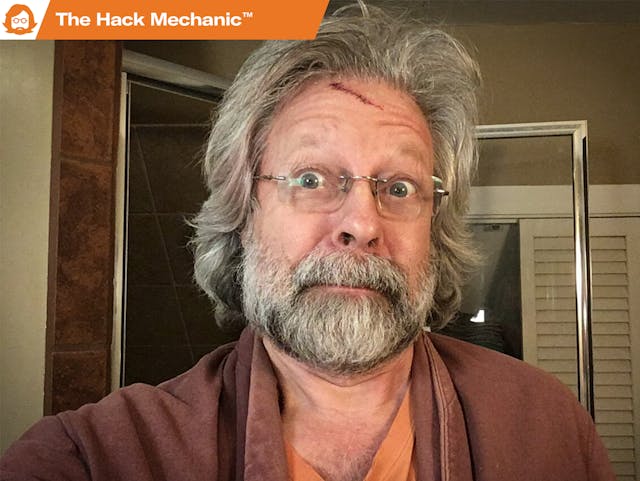

Chevy Suburban rear hatch: The gas struts on the rear hatch of my 2000 Suburban were getting weak, resulting in the hatch slowly closing after you raised it. I replaced one of them, smiled to see that the hatch was now holding itself up, reached inside the truck to get the second strut, didn’t expect the hatch to begin sagging during those few seconds, turned around, and the corner of the lowered hatch caught me right across the scalp line. I grabbed a handful of paper towels, mashed it against the wound, and staggered toward the house. A few minutes later my wife and kids arrived home to find me sitting on the front stoop with blood dripping from my face. “Father down!” I said. “Father needs assistance!” My wife looked at it and said, “Hospital, now.” (photo above)

The vicious driveshaft: I don’t work on other people’s cars for money, but I do favors for friends. The problem is that the more often you do this, the more you open up the possibility of something going wrong. In this case, prior to a road trip, one of my traveling companions asked if I could revive the A/C system in his BMW 2002. A pressure test revealed a single bad o-ring, so with a pump-down and a recharge, he had a cold car. But when we test-drove it, I noticed a very large amount of play in the shift lever. Tightening it up is usually a quick repair, so I put the car up on the lift and crawled under it while he moved the shift lever around. There are two metal-and-rubber bushings holding the shift platform to the back of the transmission, and the Allen-head bolt holding one of them had backed its way out. This was the left-hand bolt, which is usually the one that you’re able to get an Allen-key socket onto by using a wobble extension, but there was something about the five-speed installation in this particular car that made accessing that bolt difficult. Plus I could see that the hex hole was stripped. So to get at the bolt and replace it, the front of the driveshaft needed to be dropped.

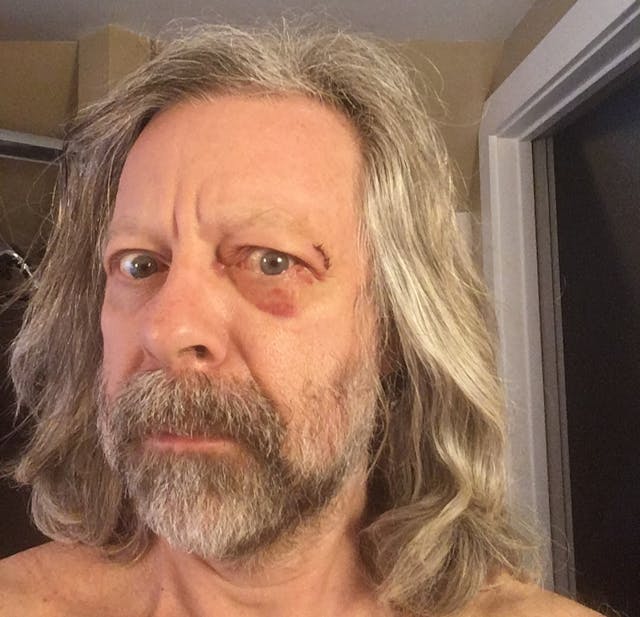

It was the end of a long day of wrenching, and I was on automatic pilot. I undid the bolts securing the driveshaft’s center support bearing, and the three holding the giubo (the rubber flex disc) to the flange on the back of the transmission. I began lowering the driveshaft but immediately found that it hit the exhaust. Fortunately, the bolts holding the resonator to the exhaust headpipe weren’t seized. Unfortunately, as soon as the resonator was lowered, the center of the driveshaft dropped with it, which freed the front of the driveshaft to swing down and clonk me right in the face, just above my left eye.

Garage wounds fall into three categories (emphasis on the gory): 1. Press on regardless, 2. Non-urgent car ride to urgent care clinic or emergency room, or 3. Ambulance. I asked my wife to triage me. “It’s not awful,” she said, “but it’ll need stitches.” I asked her to call and find out the hours and the co-pay of the nearest urgent care facility and to put a gauze pad and tape over the wound so I could finish the repair, which only took about 15 minutes. My friend graciously paid the quoted $35 co-pay, and we joked about whether a medical facility had a standardized insurance code for “hit in the face by a driveshaft.” (A doctor-friend later told me that the code is likely W20.8xxA, “struck by thrown, projected, or falling object,” along with Y92.015, “private garage of single-family house as the place of occurrence of the external cause.” He then joked, “For completeness sake, I would probably add Z74.3: Need for continuous supervision.”)

That’s most of it. Except for the time I ran over my own foot, but I think I’ll stay mum on the details. I mean a guy has to have some secrets.

***

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

As they say Experience is a teacher and a hell of a way to learn.

We all bare scars from our adventures. The key is to really be aware of what worst can happen and use that as a reason to double check or triple check things before you drop a car on a lift or lose an eye to a piece of metal from a bearing. I know a father and son both had that one happen.

But no matter what you do a wrench is going to slip or you will grab something hot and see the smoke off your fingers. I have Done that one.

The fact working on cars is filled with hazards and you are going to have busted and scared knuckle’s to show for it.

We all have bled enough to have made a good donation over the years.

The worst thing right now is the cold. I hit my hand on a Dodge truck working on it in the cold. I saw hurt in 6 ways I have never seen pain. I can still feel it today. Even with my hands half numb it hurt more than a broken finger.

I have so many. One that springs to mind was doing suspension work on one of the tow rigs during my time as a race mechanic in my 20s. Dodge dually, attempting to remove the pitman arm. Way over capacity for any of our lifts so it was on the floor on jackstands.

We didn’t have a proper pitman arm puller, so I was trying with a conventional two jaw. Thing wouldn’t budge, but I kept cranking on it hoping it would eventually pop. It didn’t, but what did happen is that the puller cocked sideways, which jammed up the screw to the point that I could neither tighten it further or back it off.

So I took to wrestling it back and forth to get it to relinquish its death grip; it eventually did, violently, on the back stroke, with which sent it right into my face. Long story longer, it punched a hole below my lower lip where the skin had gotten pinched between my teeth and the puller. Wasn’t too big, 1/8” or so, more of a slit I guess you could say, but if I pressed it with my tongue, well, I could see my tongue. So that was interesting.

I cleaned up with soap and water, grabbed some paper towels to hold against my face, and drove to the supermarket down the street to buy some super glue. That’s what it was invented for, right? Got back, super glued my face together, then went and rented a pitman arm puller from the auto parts store. The pitman arm laughed at that puller and broke one of its feet off.

I then determined that the pitman arm didn’t need to be replaced after all. I completed the job without further incident.

The hole in my face healed nicely by the way, barely a scar to show for it.

I’ve always had good luck with duck or masking tape to close a wound so I could finish the repair. LOL! I cut my arm open 1 time with a cutoff wheel on a die grinder to the point I could see the muscles inside my arm. I calmly went inside & grabbed some really big bandages & taped my wound closed & it healed up with just a slight scar. Crazy what we’ll do for our cars!

My experience working on cars, bikes and motorcycles early in life left me with, as the US Army said: “ identifying physical marks – scars on both hands”.

Don’t hold a piece of sheetmetal rust repair patch in your hand and use a 4 inch angle grinder in the other. Unless you want that piece to catch and throw into your palm and get 9 stitches. Ask me how I know, lifetime scar there to remind me.

Couple sayings kind of related to the subject:

Experience is a good teacher, but the tuition can get expensive real fast.

Experience gained is in direct proportion to equipment destroyed.

Another piece of advice I have learned over the years is let the tool do the work, as opposed to me trying to muscle it. The harder you have to work, the greater the potential injury. Use the right tool for the job. Which often means getting a longer leverage to bust something loose.

I once had a girlfriend’s 1966 Pontiac Catalina come off its bumper jack, (the wheel was already off,) narrowly missing my legs.

Another time, I was fiddling with something under the hood, with the engine running.

My inside forearm brushed against a radiator hose, and the instant reflex reaction brought my outer forearm into contact with the fan blades. A couple of impressively long cuts…

I suppose that, like many of us, we’re really quite fortunate.

Scars are the travel-stickers of our bodies.

“Scars are the travel-stickers of our bodies.”

I like that. I really like that.

Either the driveshaft incident was before the Suburban hatch incident, or the doc who stitched up your forehead was good. I didn’t see a scar from the Suburban in the driveshaft incident pic. I’m glad to see your vital facial parts were missed by objects in your misadventures, but slightly disappointed to see no cool-looking scar. I’ve had my share of mishaps, but the only memorable scars are a couple on one finger from my idiot 14-year-old self playing with the blender. I’m fortunate to still have all ten of them (fingers). I like to think that perhaps that got me started early into “avoid doing stupid stuff with tools”.

Often I now wear work gloves when using even just a screwdriver – for its intended purpose.

Situational awareness and hazard recognition are good tools to avoid injuries, but we all know we don’t always do that, and that is when the injuries occur. The two biggest things I am cautious around are grinders and lifts. That grinder can bite you in a lot of ways you just didn’t anticipate, and we all have that story. With lifts, it tends to be the people around me that I worry about, and not me or the lift itself. People have a million dumb ideas for things to do to cars while on a lift that are downright dangerous. The main thing is never put anything between the car and the ground when it is on a lift – particularly jacks. Transmission jacks are an obvious exception, but barely. A buddy of mine almost tipped a full size Cadillac off of a lift in a cramped garage after attempting to compress a front spring with a floor jack and a 2×4. If you have to do suspension work, consider keeping things on the ground.

Mr. Siegel, I’m pretty certain you are my spirit animal.

It took a substantial rust ring in my left eye and a screw driver through the muscle below my right eye (lesson learned: don’t use a large screwdriver to pop open a stuck hood latch) to get me to regularly use safety glasses. I use them for everything now, and if kept clean, they aren’t bad to wear.

Wire welding in running shoes is a similar mistake to wearing sandals while working on cars.

One of my friends was killed when a vehicle fell on him.

It seems another hobby should have been considered. I’ve been doing cars over 50 years with no scars or stories. On the road, in the race track pits or in the shop, use your brain not your head. Wearing sandals….REALLY???

Lots of near misses that go unreported to relatives and wife. I remember once pushing hard on a wrench and thought to check what I would hit if it popped loose. No sharp items, just a smooth steel surface, so I pushed hard. When it broke loose, yes, it was a smooth surface, but it was like punching a steel wall. Nothing broken, but it left a deep mental impression.

I recently learned a lesson about checking repair prices before proceeding, not on the car, but for those “couple of stitches”. Beware of ER “facility charges” not covered by co-pay or insurance. $500 for using “the facility” at a local ER!

Spinning tools seem to be my nemesis, I recall an incident from middle school shop class, and a buffing wheel that took the part out of my hand, bounced it off of the concrete wall, and sent it airborne in a perfect ballistic arc, into the back of the shop teacher’s head. Teacher down! No blood, but a visit from the EMT’s, and a subsequent lecture about shop safety. That safety class included a demo of a band saw neatly sectioning a chunk of stew meat & bone, with the reminder that our fingers were less sturdy and made of the same materials (I’m very cautious around saws to this day!) Sorry again, Mr. Drexel.

Thanks for these timely reminders. When working, and seeing myself doing something stupid… I always ask, “Is this how you want to be found, and remembered for?”

Quite honestly, the dumbest thing I’ve ever done involved a 10 foot step ladder and a boat propeller. A story for another day.

Dave, yeah, I ask myself that too.” Maire Anne and I joke that if I die in the garage, she’d kill me.

When I was 12 I took all $52 of my savings and bought a boatload of Craftsman tools (1967, still have all the tools) so I could work on my newly purchased $35 1956 Chevy. My father told me the only truth he ever did when he said “Be careful. Wrenches can slip and you’ll skin your knuckles.” My thought was “Stupid adult-sure, that will happen once and then I’ll know how not to let it happen again.” I think I may have been surprised the second time i skinned my knuckles. By the 10th time I pretty much had figured it out that this is a part of working on cars. Now I’m so experienced that I know exactly when it’s going to happen.

Some old big block Mopars had the ignition coil mounted just behind the carb on the intake manifold. No big deal with the original carb which had the idle air adjustment screws in the front. When you installed a Holley double pumper, the rear adjustment screw was in close proximity to the coil. If said coil (or coil wire) is leaking voltage, it will arc to the screwdriver you are using to adjust it causing your arm muscles to contract and, as it turns out, stab yourself in the chin with the screwdriver. I think we all know how I know that.

1962, just bought a transmission for my 1954 Chevy Belair stick shift from the local wrecking yard for $15., (guaranteed…and it worked fine for years) Car up safely on 4 sturdy jack stands. Removing bolts that held driveshaft and universal joint to rear end to slide said “driveshaft” out for transmission swap. Did not know it was indeed a ‘torque tube’, and all the weight of the car was released downward with the end of it missing my head by inches and taking a chunk out of the cement floor.