Trouble with the truck. Again.

After putting a lot of thought into dealing with the 34-year-dead, numbers-matching engine to my 1973 BMW 3.0CSi, I was prepared to go over to what used to be my mother’s house in Brighton and drag it back to my house in Newton. I’d already elicited my youngest son’s help to ratchet-strap the greasy lump onto a furniture dolly. The trussed-up, numbers-matching turkey just needed to be winched into the back of a rented U-Haul trailer. I loaded up some odds and ends into the only-slightly-mouse-infested truck (the 2008 Chevy 3500HD Duramax diesel), turned the key, and …

Oh, dear.

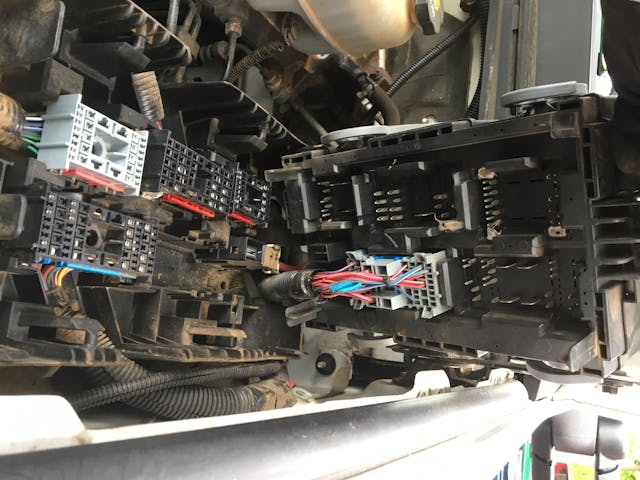

Last fall, I wrote about a frustrating crank-but-no-start problem that vexed the truck for nearly a week, then vanished without my really having identified the cause and fixed anything. I’d read about a problem that this generation of Duramax diesels have where any cracked fuel lines or worn o-rings can cause the fuel pump to suck air rather than fuel, but because the truck had thrown a P2510 code and this is also correlated with cranking but not starting, I went down that electrical rabbit hole, checking grounds and disassembling the fuse box looking for corrosion and not finding anything wrong.

At some point, I cycled the central locking (and with it, the alarm system), and the truck started as if nothing had happened. I chalked it up to the alarm and locking systems somehow having gotten out of sync. The problem never recurred.

Until yesterday.

Now, when someone says that their car or truck died and they have to sell it because they “no longer trust it,” I usually roll my eyes. Nearly all automotive problems can be solved. As I say over and over, the main things that cause cars to die are fuel delivery issues, ignition issues, cooling system issues, charging systems issues, and belts (and on vintage cars, add clutch hydraulics and ball joints). These are all solvable problems. People may say they’re selling a car because they no longer trust it, but odds are that the driving forces are really the superposition of age, mileage, repair bills, changing family needs, and the desire for something newer and nicer.

However, the truck is different. It’s a big dually diesel that the company I worked for purchased to tow a 32-foot trailer. I bought it from them for a song when they all but abandoned it in a parking lot and mice got into it. Because of the big utility body on the back, it’s often mistaken for a commercial vehicle (it was a commercial vehicle). Insuring, registering, and getting it inspected in the state of Massachusetts took a bit of doing, as I had to find people who understood that you can have a 10,000-lb GVWR truck registered that way. But the combination of the truck’s size and weight, and the fact that it’s a Duramax diesel, means that if it breaks down on the road it’s going to be more difficult to deal with than a passenger car, and any repairs are going to be expensive. And that’s even before considering the nightmare scenario of it dying while I’m towing something.

So my first reaction to the return of the mystery cranks-but-won’t-start problem was, in fact, the very one that I scoff at when I hear others speak it: “If I can’t trust the truck, I’m going to have to sell it.”

Fortunately, the no-start couldn’t have happened in a better place than my own driveway, and I had no hard timetable for using it to move my old numbers-matching engine or anything else, so I calmed down, rolled up my sleeves, and had at it. This time, because there were no DTC codes when I plugged in the $25 code reader (which I keep in the truck for exactly this reason), I focused on the fuel delivery system.

Diesel trucks like this are outside my mostly-small-European-car wheelhouse. I did some reading and learned that most diesel pickups have an engine-driven mechanical injection pump that generates the thousands of PSI needed by the injectors, as well as a secondary “lift pump” to get the fuel out of the tank and up to the engine. However, the GM Duramax diesels built between 2001 and 2016 weren’t equipped with a lift pump, the logic being that their Bosch CP3 and CP4 mechanical injection pumps were capable of generating enough suction that a lift pump wasn’t strictly necessary. This means that, in order to prime the fuel system (to get it full of fuel so it’s not sucking air), you have to rely on the big push-button that sits on top of the fuel filter head. You take a screwdriver and open up the bleed valve located on the top of the housing, pump the button until fuel without air bubbles comes out, close the valve, then continue to pump until the button feels hard.

This all works fine until it doesn’t. Aging fuel lines and rubber seals in the filter head can make it so the fuel system “loses its prime” and doesn’t regain it even with repeated pumping of the push button. It turns out this is a fairly common problem in Duramax diesels. However, when I began reading about installing a lift pump, the applications I saw had to do with increasing power for towing big loads on long hill climbs, something I’m unlikely to do. It took me a while to understand that the lift pump also solves the priming problem.

Initially, I was skeptical that the truck had a priming problem. It had only been sitting for a few days. I’d previously let it sit for weeks without having this happen. And I pumped and bled the fuel system twice, to no effect. But when I tried it the third time, after closing the bleed valve, I kept pushing the pump button until it was rock-hard and my thumb was sore, and the truck fired up. I had to admit that the diagnosis fit the symptoms pretty well.

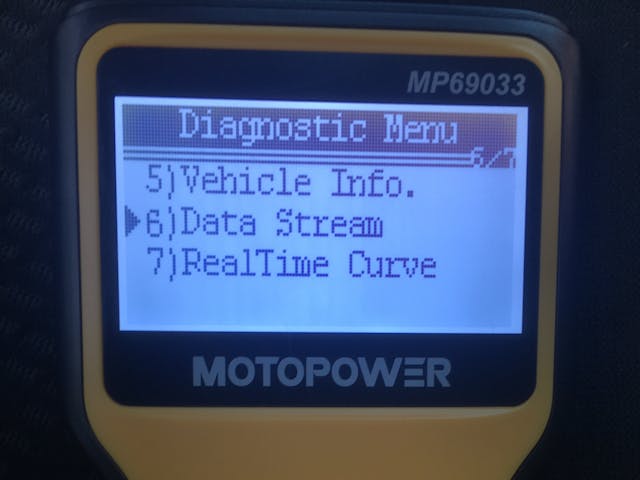

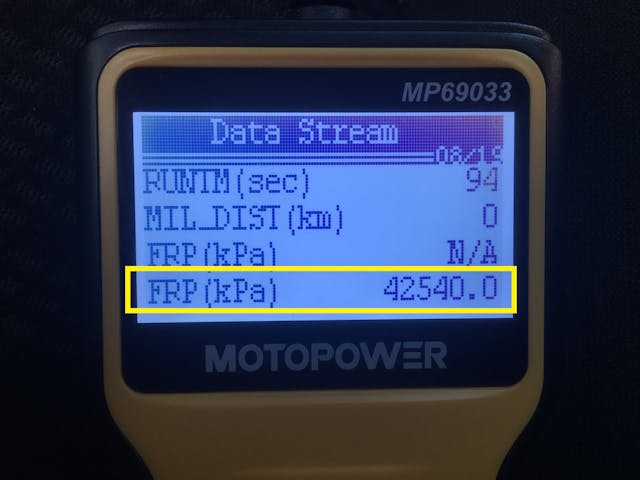

I also watched several diagnostic videos where people trouble-shot crank-but-no-start problems on Duramax diesels by using a scan tool to look at fuel rail pressure (FRP). I thought, “OK, so I need to spend the money to buy a GM-specific scan tool—this $25 OBD-II code reader I keep in the truck isn’t going to do that.” But when I read further, I learned that fuel rail pressure should be part of the data stream supplied by the CAN OBD protocol, and that even an inexpensive code reader should display it. Sure enough, with the truck running, I could see fuel rail pressure of 42540 kilopascals—about 6200 PSI.

When I got the truck started, my initial reaction was to drive it directly to a nearby repair shop whose parking lot is routinely full of dually diesel landscaping vehicles, but now that I was armed with a) the knowledge that it was a priming problem, b) a data point that it started when I fully primed it, and c) the ability to confirm fuel rail pressure if the problem recurred, the my-truck-isn’t-reliable-what-am-I-going-to-do cloud dissipated, and I felt like I had some space to look at which solution to implement.

As with many problems, it depends how much you want to spend.

The least expensive approach would be to spend 10 bucks and buy a rebuild kit with the o-rings and seals for the pump filter head. If you’re going to go that route, the pump filter head has to be removed from the side of the block, so you might as well also spend the $120-ish bucks to replace the two rubber hoses plumbing the filter head. Of course, no-start problems can also be caused by collapsed fuel lines at the back of the truck. So down the rabbit hole you go.

The next improvement you can make is to spend about 100 bucks to purchase an adapter plate you can install on the underside of the filter head to allow use of a 2-micron Caterpillar 1R-0750 filter (the stock filter has a 10-micron mesh). Unfortunately, this does away with the stock water separator, so you either have to add it back in a different way or go for a lift pump where it’s integrated into the package (below).

While there is an available in-tank lift pump, most are external kits that combine a pump, a 2-micron filter, and a water separator. If, like me, you’re coming at this from the background of adding a $50 electric fuel pump to a vintage carbureted car to deal with priming empty float bowls after a winter-long sit, you’ll get sticker shock—the lift pump kits from AirDog and FASS seem to start at around $650 and require a some amount of fabrication to install in such a way that they’re not waiting for a stray rock on the highway to take them out.

So, I’ve got some decisions to make. If you’re like me, you don’t mind spending money on cars when it’s something that improves appearance or performance or comfort, but you bristle at paying for parts or repairs that merely return the vehicle to a baseline. After spending nearly $800 replacing the truck’s stolen catalytic converter, looking at spending nearly that on what’s essentially preventive maintenance isn’t a slam dunk. Still, as I often say, vehicles are not organic systems. They do not heal themselves. Problems don’t get better. They get worse. This truck has now exhibited this problem twice. I’d be an idiot not to deal with it, and I try to not be an idiot.

I’ll let you know what happens.

***

Rob’s latest book, The Best Of The Hack Mechanic™: 35 years of hacks, kluges, and assorted automotive mayhem is available on Amazon here. His other seven books are available here on Amazon, or you can order personally-inscribed copies from Rob’s website, www.robsiegel.com.

A tough call to make Rob. Good luck!

I recently went through this. My 2000 F350 diesel developed some issues, and I ended up putting it in the shop for the first time since I’ve owned it (only about 4-5 years). It cost over $800 for the engine repair, and I also just found out it needs $1,500 of front suspension repair. I’ll be able to rebuild that, with the exception of the alignment for quite a bit of savings. I considered selling it and buying something else, but I decided to just fix it. In the end, I have a truck that’ll do everything I need it to, and still be in it way less than a newer truck. With the engine work done, my confidence has been restored. If you need a truck, you won’t be able to be in one any cheaper than the one you have now. And if you don’t need a truck, with the fuel prime issue fixed and the low miles yours would bring a lot of money that could go to other projects. Or even a vintage truck that’ll do the occasional hauling you need, plus some left over for other projects.

Rob, I can relate. I’m running a 1995 Chevy 3/4 ton for towing duties. Whenever I feel the pinch for parts or repairs, I look at what new trucks cost and that eases the pain. Good luck with your decision. Joe

Not a Duramax owner but…

While your 6,200 psi FRP is good for idle (being well above 5,000 psi min) the full throttle FRP is on the order of 26,000 psi and that may not happen with just rebuilding the pump head seals and rubber hoses. However, I would go there first, before adding other pumps, filters and separators. In fact I also would replace the rear fuel lines if I thought they were collapsed or past there best used by date. I’m basing this on how often you think you are using the truck, and whether you truly need to add the better filtration and lift pump.

Agreed. I own a 2006 Jeep Liberty CRD and, at least according to what I read on online forums, it is a fairly common “upgrade” for owners to install an in-tank lift pump from a Cummins Dodge truck. Apparently, the wiring is all there, too.

However, I have always been able to diagnose and repair fuel system air leaks and see no need for the extra expense or complexity of additional pumps when the engineers didn’t. If it were mine, I would fix what’s wrong rather than try any sort of band-aid solution.

I completely understand. I’m in a similar boat with my Honda Fit. Do I spend the money on a new exhaust system including the catalytic converter and O2 sensors, then rebuild the suspension only to have an old car which has nearly 250,000 miles on it? Do I trade it for something newer or nicer? It doesn’t fit my use case like it did 200,000 miles ago, so I’m torn.

Okay, that’s a trick question. I will fix it properly and one of my teenagers will drive it so dad can have something newer and nicer!

“I’d be an idiot not to deal with it, and I try to not be an idiot.” I love the wiggle room in the second clause!

Rob, while your explanation of the basics in troubleshooting no-start problems is correct, it’s not entirely always the case.

Case in point: my 1991 Chrysler Neon. It would just die at inconvenient times, like when my wife was at the grocery store. No symptoms except… dead. Key in ignition would show proper dummy lights but no crank. By the time I’d arrive to help, it would start. It *seemed* like a random event and also *seemed* like it would go away after maybe 10 min.

We took it to the dealership several times, but they could find no fault. This (of course) because it never threw a code (more later) and always worked for the dealer. Until the last time. We left it at the dealership at a point it was happening with too much regularity AND seemed to be coincident with cold mornings. The dealership tried and again no issues until the following morning. Then… SUCCESS!!! It would not start and they managed to pull a code, which VANISHED the moment it finally started.

But they had a code! And the code was the reason not all problems are as straightforward as you mentioned in your article.

You see, the Neon code was thrown by the computer and indicated (in essence) “someone is stealing this car”. It would then shut down because the security feature detected this “theft” situation. Except… the neon DOES NOT HAVE ANTI-THEFT features. Not at all. What???

Turns out they used (at the time) the same computer for many models. Another fancy Chrysler had anti-theft, and the same computer was in our Neon. It turned out (after some further diagnosis) the computer epoxy resin packing had cracked, and moisture was getting to the connectors, including the one for the fancy car anti-theft sensors. Because they had the same programming, just missing the sensors, the fault would then trigger the anti-theft shutoff.

New computer (under warranty) and the problem never returned.

It sounds like you are on the right track. I guess it depends how much money you want to put into it but I assume the truck is paid for.

Here is my head scratcher story.

Back in 2012 we bought our 16 year old son a 2009 Mazda 6. It was a real nice car, the top of the line Grand Touring model with the V6 and the button start whereas lesser models had the keyed start. The Carfax did disclose that it was in a minor accident, but looking it over it was pretty solid, low miles, very clean and a nice car with a ton of features that for it’s year, you would find in much more expensive vehicles.

Car ran great, but every once a while, when you went to push the ignition button, nothing would happen. No crank, nothing. There were also a couple of instances where it would just die while driving (which was much more concerning) and the CEL would illuminate. After the first time I pulled the code and it stated “Lost communication with ECU”.

Pulled and reinserted the ECU fuse and the car would start. Months would go by and the problem would happen again. Same code, same process to get it to start again. At one point we were told it was weak batteries in the fobs, so we replaced them in both, but I wasn’t convinced since the security system light would illuminate once you put your foot on the brake before starting. The light would be green if it recognized the fob, or amber if the fob wasn’t detected and each time the light would light GREEN so apparently it sensed the fob. Additionally, since the push button feature was only on the higher trim models, what Mazda did was place a plug over where the ignition key would go on the column and put the push button on the center console, and the procedure if the fob wasn’t working was to pop off the cap on the column, take the key out of the fob, insert it into the column so it could read the key, and then push the start button. Tried that and it still wouldn’t start unless you did the fuse pulling procedure. So that ruled out the fobs.

Then for a LONG while, the problem didn’t reoccur and the car would run with no problems. about a year or so later my son ended up getting another car and at the same time my mom was in need of a vehicle, so we gave it to her. She was thrilled, until all of a sudden the issue resurfaced. Again, intermittently and with long times in between.

She then noticed that every time it seemed to occur was after she made a left turn. We finally decided that it was time to take it to a dealer.

Sure enough it took them only a few minutes until the service manager came out and asked if the car had ever had body work done. We told him that there was a history of a minor accident.

Apparently the accident must’ve been on the driver side fender. When they were repairing the fender they must’ve popped off the fuse block that sits right next to the fender, but when they went to put it back they didn’t seat it completely. There was just enough contact for the car to be just fine 99.5% of the time, but if there was just enough body flex (like making a left hand turn), the connections would lose contact and shut the car down.

Dealer seated the fuse block and the problem never resurfaced again. This was probably over four or five years ago and my mom is still happily driving the car.

My guess is the previous owner must’ve had the same issue and because it was so sporadic it was difficult to recreate. They must’ve felt that they could no longer trust the car so they got rid of it.

We’ve all heard the line when we take a car in for an intermittent issues, “car runs fine, couldn’t recreate the problem”. Thankfully the dealer we went to thought to check the fuse box and not jump right to swapping expensive parts such as the ECU.

I understand your dilemma. I have a 79 F150 that is very handy when I need it, but it also is getting to be a time thief more and more, and unsheltered I hate to watch it deteriorate. I may sell and rent as needed, or use a small utility trailer, but you get attached to vehicles after a while (35 years in this case). Yours may be a good cash source if you sell it; it’s still pretty shiny and should fetch a good sum that could be spent in some fun ways.

When I hear people say something like “I have to sell it because I no longer trust it”, I wonder if they are planning on being totally truthful with any potential buyers, of it they are just contemplating “unloading” their problem off onto someone else. Most people, I suspect, are not going to jeopardize their best price – or even the sale period – by elaborating on all the unsolvable and/or expensive issues with a vehicle they are selling because it’s failed them somehow. I mean, that’s why the banana-peel-in-the-tranny was invented, right?

Good methodology displayed here, Rob. I love the sequence of discovery which you use! jay

I went through something very close to what you have going on with a Mack diesel truck that i owned years ago. It had a mechanical fuel pump system with a hand priming pump so that the system could be primed after a fuel filter change. Mine turned out to be the seals on the primer shaft were getting bad and it would occasionally not seal to the shaft completely allowing the fuel to siphon back into the tank. I would recommend the rebuild kit for the primer pump as a first line of attack and go from there. Might be the cheap and easy fix before going all in on the lift pump system.

Rob I have the same problem with my 2003 duramax.Broke down in the driveway so started eliminating what I could,rebuilt the primmer pump.It fired up but after letting it sit overnight lost it’s prime and back to square one. Not trusting the rebuild,because there are two components in the pump that are not able to be replaced , I bought a complete pump and replaced the rebuilt pump.It would fire up but when it sat over night lost it’s prime again.Reluctantly I fired it up and drove it to a trusted deisel mechanic.Ran fine getting there ,no issues at all,let it sit lost it’s prime .He ran extensive diagnostics on the fuel pressures,vacume and pressure on the fuel system, no issues. Checked the injector flow ,came up with two bad injectors and one that is on it’s way out.Now facing a bill of 6-8 thousand dollars for injectors and diagnostics . Can’t replace the truck for that amount but OUCH .

Man, that’s painful.

Had a loss of prime issue with my 2009 LMM duramax. Turned out to be the fuel Schrader valve was leaking . Went to unfasten it from the steel fuel line and it twisted off flush with the steel fuel line. If you unscrew the cap and start the motor you can see if it is bubbling or not, if it is it needs to be replaced. But………to replace the steel fuel line is crazy. While you have it that far apart, you may as well service the EGR system, check your water pump and the many hoses for seepage, check your plastic crossover pipe for cracks/leakage, examine closely all your wiring and connections, and the whole host of other issues. I temporarily fitted a piece of fuel hose over the breakage and connected the new Schrader valve with clamps. This is the most difficult motor I have ever worked on due to its lack of accessibility to repair.