Insights on being well-grounded

Whenever anyone mentions having an electrical problem with a car, someone always gives the well-meaning advice to “check the ground.” My experience is that this isn’t the slam-dunk many think it is—I’ve found that most electrical issues are instead tied to bad components or the connections between them.

Of course, sometimes it is the ground. The most dramatic example is with a poor engine ground connection when trying to start the car.

Witness the situation that occurs in the vintage BMW world where I spend most of my time. Someone will pose a question to bmw2002faq.com—the hive mind of 2002 information—asking, “My 2002 wouldn’t start. I turned the key and it wouldn’t crank at all. Then I hit the accelerator pedal, tried again, and it started right up. But afterward, there was a bit of a burning smell from under the hood. What’s going on?” Those of us who have seen this before can answer the question immediately because the symptom is so specific.

On every car, the battery’s negative terminal is attached to two places. The first is the car’s metal body. This provides the common ground path for every single electrical device.

Well, except for one—the starter motor (and any other electrical devices that are integral with the engine). Because engines have rubber mounts to prevent their vibration from telegraphing through the body of the car, they are usually not grounded without a second ground connection from the negative battery terminal directly to the engine. Whether there’s a single Y-shaped ground cable connected to the negative battery terminal where one strap goes to the body and the other to the engine (as is the case on a BMW 2002), or a ground strap from the negative terminal to the body and then a separate one connecting the body to the engine, varies according to make and model.

Both of these ground connections must be present for the car to start and run properly. With age, it’s not uncommon for one or both of them to fail due to the braided strap corroding and breaking. If the engine strap is intact but the strap to the body has failed, the engine should still crank, but other electrical components may work intermittently, if at all. Conversely, if the chassis ground strap is fine but the strap to the engine has failed, the lights, fans, etc., should all work fine, but with no direct grounding of the engine, the starter probably won’t crank.

I use words like “may” and “probably” and phrases like “if at all” because if one of the ground straps fail, there can be “unintended ground paths” that may allow current to flow though the other one, at least until enough current flows through something that it’s not supposed to that something burns up.

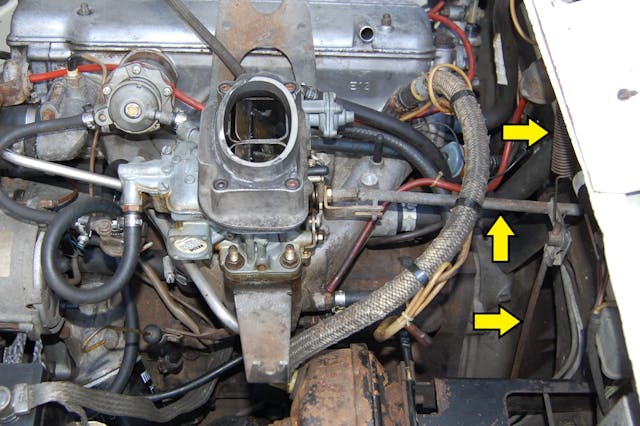

And, with that background, I can explain the strange condition where a BMW 2002 won’t crank until you hit the accelerator pedal, then starts, followed by a burning smell afterward. As shown above, the negative battery cable on a 2002 is a braided Y, where one braid goes to the chassis, the other to the block. When the braid to the block corrodes all the way through, the engine has no direct ground path. After all, the engine is on rubber mounts, as is the transmission, the shift platform, and the exhaust.

But there is an “unintended ground path” and it’s quite a surprising one. It’s the accelerator linkage. The linkage is a series of metal ball-in-socket rods. There’s a lower rod that connects the accelerator pedal to the throttle linkage rod. One end of the throttle linkage rod is connected to the carburetor or injection pump (which, in turn, is connected to the block via the intake manifold and head). The other end goes into a plastic bushing in the firewall that supports it and aids in rotation.

Wait. Plastic doesn’t conduct electricity, right?

No, it doesn’t.

So how is this a ground path, and how does hitting the accelerator pedal make the starter crank?

This is the fun part.

There’s a throttle linkage return spring about the diameter of a fountain pen connecting the linkage to the firewall. Unlike the rotating end of the throttle linkage rod itself, the spring isn’t sitting in a bushing. The top is just hooked over the cowl and sits in a small hole in the metal. Similarly, the bottom spring hook is in a hole in the linkage. Over time, the paint in the upper hole wears away, allowing metal-to-metal contact. Poor metal-to-metal contact with an inner coating of rust, to be sure, but contact just the same.

So, hit the gas pedal, it stretches the spring, which pulls the hooked ends tighter against their metal holders, maybe jostles them around in the holes. Turn the key, and suddenly hundreds of amps of current find a ground path. They flow through this little piece of metal like an entire city’s water supply being shoved through a soda straw. With all that current, the spring can literally glow like the similarly-shaped elements in a toaster. So, yeah, there can be a smell.

Credit for discovering this rather remarkable failure mode and disseminating the knowledge goes to my BMW 2002 colleague Mike Self, but being an old guy who has seen it happen, I get to act like I’m a wizard when someone describes the symptom and I blithely nail the solution as if it’s the product of deductive reasoning instead of my friend Mike having told me.

I just encountered a pretty cool variant of this issue on a modern car. My friend and neighbor Dave has a 2014 MINI that wouldn’t crank. I walked two doors down to check it out. The battery read 12.6 volts, so it appeared to be fully charged. I connected my battery jump pack, and tried four times. On three of them, nothing happened, but on one, there was the CLICK of the starter solenoid. The rest of the car’s electronics seemed to work, just not the starter.

As I was musing whether the problem could be caused by the interlock that prevents the starter from engaging unless the clutch pedal is depressed, Dave said, “When the car was in for service last year, the mechanic said that the ground strap was corroded. Do you think that could have something to do with it?” He then showed me a video that the mechanic shot, clearly showing a ground strap green with corrosion, and a weak spot forming at the strap’s connection to the chassis.

It made perfect sense to me that this was the problem—the strap had corroded through, or nearly so, and the engine no longer had a valid ground connection.

To be clear, Dave wasn’t asking me to repair the car. He was just wondering what I thought was going on, and how serious the problem was. And besides, in order to replace the ground strap, I’d need to jack the car up, set it on stands, and pull off the engine’s under-cover—and his driveway, where it was parked, was too uneven and sloped to safely do any of that.

Dave isn’t a car guy, but he’s smart enough to have asked me the following very interesting question:

“Is there some way to ‘jump’ the ground path?”

A light bulb went off in my head.

“Do you have a set of jumper cables?”

“Sure.”

Like most cars these days, the MINI is a front wheel-drive car with a transverse-mounted engine, so instead of the engine mounts both being just above the oil pan like they are on an old-school rear wheel-drive car, one of them was up high, connecting to the right inner fender wall. I clamped one end of a jumper cable to the big aluminum bracket connecting the engine to the mount and the other end directly to the battery’s negative post.

I then had Dave start the car. It took a couple of tries with me reseating the jumper cable’s clamp and pulling the ends of the handles apart in order to get their teeth to bite more firmly into the bracket, but the MINI started. It certainly removed any question that the problem was due to the engine not being grounded. And from the video, the root cause of that was almost certainly the corroded ground strap.

Dave asked if I could drive the car to the repair shop. I carefully disconnected the jumper cable providing the ground path. The car continued to run, but we both heard a sharp click, likely an electrical relay—one that also relied on the electrical ground path through the engine—de-energizing. If this was an emergency, I could’ve gone to AutoZone, bought a beefy generic ground strap, and connected it semi-permanently from a good ground point on the chassis to a good ground point on the engine. But it wasn’t, plus Dave had AAA, so after a free tow and a small repair bill at a local shop, the original ground strap was correctly replaced.

This is a good thing to be aware of, and a good work-around to be able to put in both the mental and physical tool kits. Now, you can be the wizard who pulls this out of his bag of tricks at a car event and saves the day. Extra credit if you can point to a spring glowing red like a toaster.

Hey, everyone likes to feel well-grounded.

***

Rob’s latest book, The Best of the Hack Mechanic™: 35 years of Hacks, Kluges, and Assorted Automotive Mayhem, is available on Amazon here. His other seven books are available here on Amazon, or you can order personally inscribed copies from Rob’s website, www.robsiegel.com.

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

Learned this the hard way years ago when I burned my hand on a surprisingly very hot choke cable. Took a few minutes to figure out my ground strap was broken—and a few weeks for the spiral cable burn to fade.

It’s usually the problem with trailer lights. I’ve often used jumper cables or lengths of insulated wire to locate the problem. Boat trailers often rust and lose the ground between the tongue and the frame where it’s bolted to.

My boat has a Chev inline 6. One time the battery died after turning the engine 5 or 6 times. I had just charged the battery so it surprised me. I checked the battery connections and burned my fingers on the red hot ground cable. It was badly corroded under the insulation. A new cable and a jump saved my fishing day.

I learned it some 40 years ago assembling a first generation Camaro thinking “There’s GOT to be enough metal-to-metal contact to not need this other cable”. That contact turned out to be the hard fuel line.

I used to do a lot of electrical work as part of owning a specialty off-road shop, and people would always ask why I used giant ground cables in multiple places. I would have loved to have pointed them to this article. Ground it and ground it again.

Keep in mind that the voltage will dictate size of battery cables! My 1955 IHC R110 has a 6 volt system and a 2/0 gauge cable is recommended! Use of any lighter gauge can lead to decreased cranking power and/or melted cables.