The sins of the father—or the previous owner

The vehicles we love so much come from a family of objects that have been proven to last centuries—assuming they’re cared for. The hands of time are cruel, though, and pretty much anything enjoyable you can do with an old machine will expose it to all kinds of damaging factors. Whenever the subject comes up, I’m reminded of how classic-boat people say restoring a wooden boat is like rebuilding a grand piano and then throwing it in the lake.

Restoring a car or motorcycle, in other words, is the easy part. Bad things attack only once you go to enjoy it. On a long enough timeline, everything returns to carbon, sure, but in between, we have to have fun. Therein lies your responsibility.

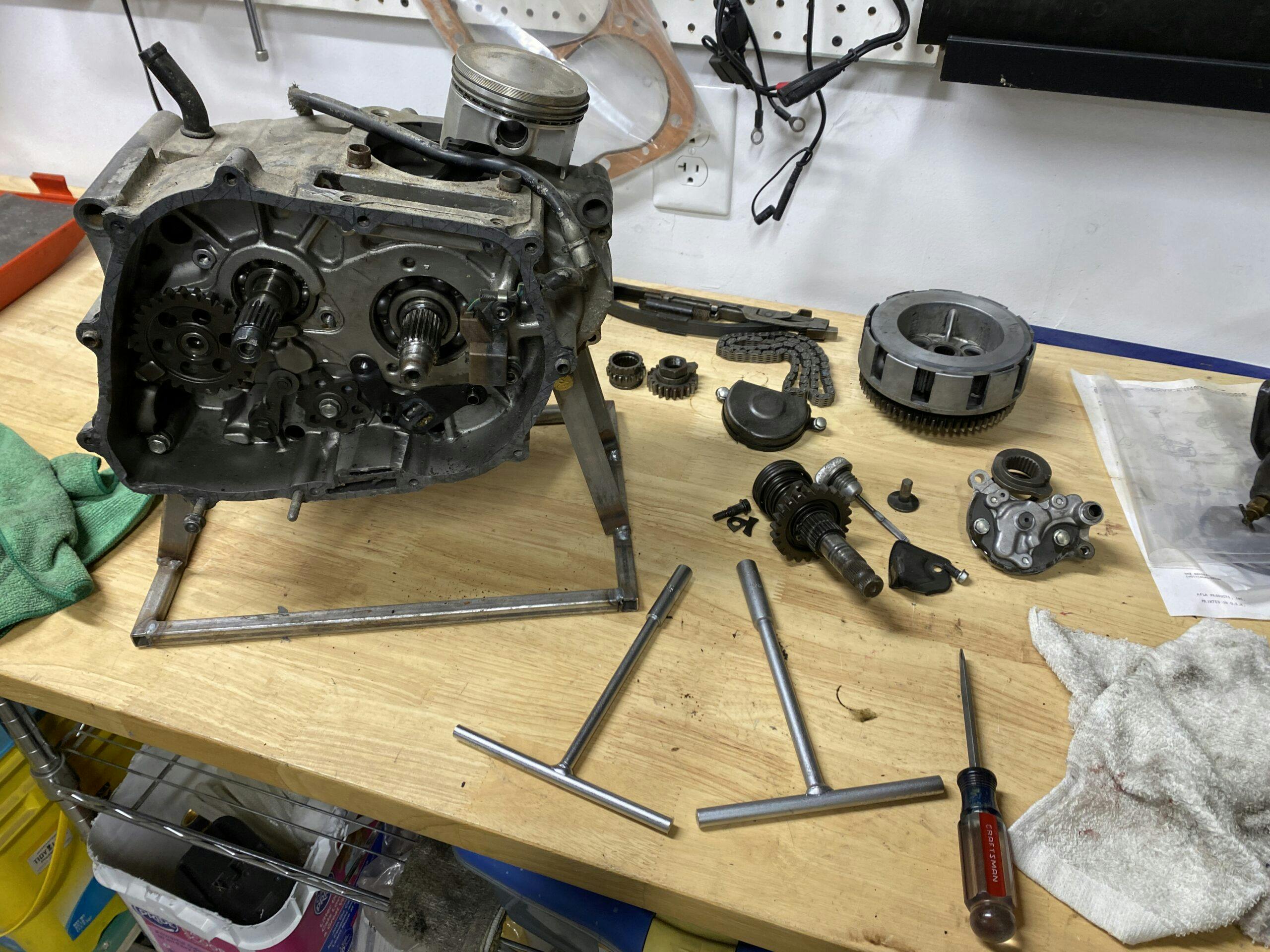

By way of example, I recently pulled two engines off my storage shelf. Each was removed from a motorcycle that I purchased for parts and was assumed to be nothing more than parts—a core that would one day be restored, piece by piece, keeping little more than the casings. When I brought those engines home, I naturally held out a bit of hope that more than a few of their parts could be reused, but in situations like this, it’s always better to walk in assuming the whole thing is garbage, then be pleasantly surprised if it isn’t.

Tearing down an unknown engine is a time when even a vehicular optimist like me gets pessimistic. Me, the guy who was gung-ho about throwing an old farm bike onto a track with purebred road racers. Few people’s glasses are more rose-colored than mine when evaluating a project vehicle . . . until I start thinking about engines. Then it’s gloom and doom.

No sane person would assemble a motorcycle they actually intend to use around an engine with unknown history. I don’t remember what the seller told me about this particular pair of powerplants, but even if they had said each was a fresh rebuild, I wouldn’t try to run them. Trust but verify, and all that. What a letdown it would be to drop the kickstarter on a freshly assembled bike only to be met with a wheeze and enough blow-by smoke to fog half the state.

Open-heart surgery on a freshly painted bike is a nightmare I have endured and won’t subject myself to again. I value my time pretty low, but not that low.

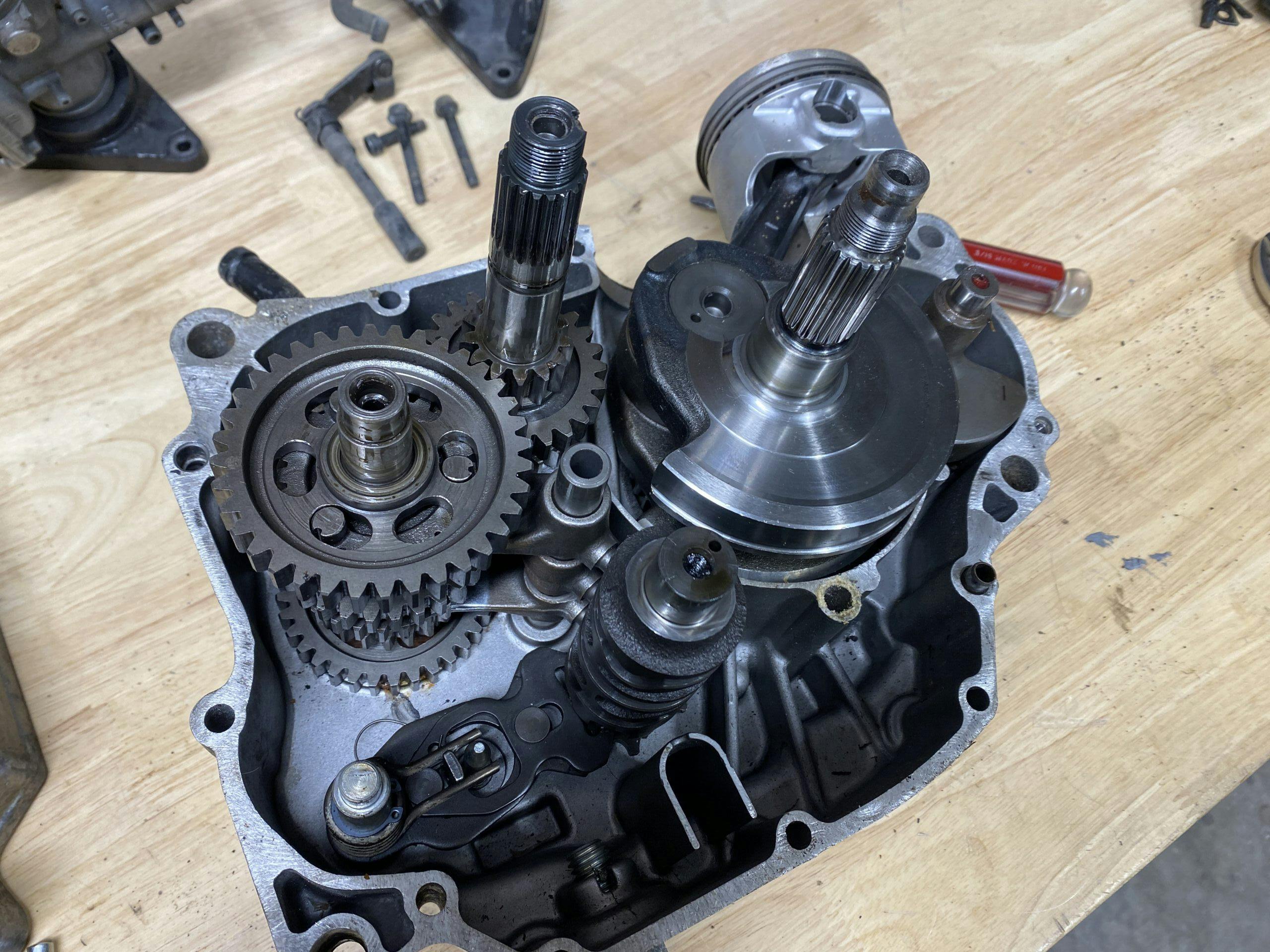

Beyond that, there’s this weird feeling that I owe something to the parts themselves. To do right by them. Each of these 250-cc, single-overhead-cam singles was originally installed in a Honda XR250R in the late 1980s. The cylinder heads are aluminum, with the cam supported by three bearings. The outer pair use drop-in roller bearings, but the center bearing is a smaller, machined-in-place plain journal—the head itself is the bearing surface. Insufficient oil flow will cause cam and head to destruct in a manner typically reserved for reality-TV relationships. Everyone leaves scarred.

Repairing that damage isn’t easy. The cam can be saved, at least, if you have the center journal welded up and ground back to the correct profile. The head, however, is designed in such a way that it simply has to be replaced. The shape and arrangement of the cam saddles complicate the possibility of a simple weld-and-machining repair. The weld itself wouldn’t be difficult, but properly reshaping the aluminum saddles would require a special cutter and multiple special fixtures.

The measurements that define the location of that center bearing in space are unique. A really good machinist could probably figure out how to effect a repair, but they would basically need a copy of the engine’s original plans from Honda, or at minimum, a known-good original part from which to reverse-engineer a process and tooling.

(I haven’t met that machinist yet, but if it’s you or someone you know, email me: klsmith@hagerty.com)

Making matters worse, new-old-stock Honda XR cylinder heads are basically unobtainium. If you can find one, the part is comically expensive even considering the fairly strong state of the XR market. If these bikes ever return to their lower, pre-2020 prices, things will get even worse. These are motorcycles bought by a lot of people—including myself—for a dollar or two per cubic centimeter. An XR250R that doesn’t run? Five hundred dollars is fair.

In other words, if you’re about to throw a new-to-you engine into service, a little diligence goes a long way. Would I risk borderline irreparable damage or a total write-off to one of these motors simply because I’m too lazy to pull a side cover and check the health of the oil pump? Nope. We owe this kind of attention not just to the machine, to the mechanical work of art, but to the next owner, and the owner after that, ad infinitum. We all want our cars and bikes to be remembered forever, right?

This kind of thinking applies even to small tasks. It may take a little more time and an extra trip to the toolbox to get the right wrench so a bike’s original hardware can be reused. Why throw away originality over a few steps, let alone cost yourself the price and headache of finding replacement parts, simply because you damaged something through lack of care? Caring is free—it can happen regardless of the size of your bank account.

Those heads aside, one of those Honda engines also has a stripped drain-plug hole. A previous owner or mechanic overtightened the plug, probably trying to cure a leak, and cracked the engine case.

Do I technically need these cases? No—but I’m not going to be the one who lets a repairable part go to waste.

I owe it to the machine to do my best. To repair the flaws I find properly, rather than create a ball of Band-Aids for someone else to deal with. I didn’t create the problem, but I’m the one who’s going to solve it.

***

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

I agree with and applaud Kyle’s attitude about fixing whatever you find that can be fixed – until I get to wiring. Then I’m the biggest band-aid guy in the world. Run a new wire alongside an old one and tape it in place just so I can get power to something? Sure, no problem. Cobble a few different harness segments together? Absolutely. Just clip off some wires that I don’t see any use for (as opposed to tracking them down)? Do it all the time. I love to correctly fix “mechanical” issues – but wiring and electrical stuff have kicked my behind so many times that I just can’t bring myself to plunge myself into that particular fray anymore. 🙄

Short of replacing the entire wiring harness, a repair involves compromise. It’s not as good as new.

“repair involves compromise” is a very true statement most of the time. Hadn’t thought of it that way!

Doing The Right Thing. I think of it as making the world a better place, one vehicle at a time. Maybe it’s the mentors who survived The Depression and WW2 still informing my standards, but it troubles me when things go to waste, especially something that was cleverly made.

It’s a fine line to walk between keeping anything that has value because I can repair it and drowning in spare parts like a hoarder. Maybe one day I’ll devise a plan to guide what I keep and when I clean house.

“I didn’t create the problem, but I’m the one who’s going to solve it. ” – A great rule to live by.

Amen!

It really is. And the best way to learn too!

I feel your pain when it comes to repairing some of these Honda single heads. From what I experienced the center journal doesn’t allow for a line boring type operation. I’m sure someone will come up with some sort of bushing /insert combo that will locate itself into a machined pocket that you could shim to height using plastigage. Not cheap, takes some skill. Hence the term… “is the juice worth the squeeze.”

And honestly I am not sure the XR community will ever view the juice worth that kind of squeeze. I view it as a fun challenge to greater understand how things are produced since you basically have to understand how it was built in order to properly re-build it. Sure, lots of people “fix” things without that kind of understanding, but I think we have all interacted with those types of repairs…

This article reminds me that there is no substitute for cast iron simplicity. I bought a “junk” A series 948 Sprite engine at the swap meet for $100! I really didn’t need the engine but at that price I figured I could salvage a crank or a head or something even a rocker arm assembly and make it worth my while.

So when I brought the whole mess to my machinist I wasn’t expecting much and upon inspection #4 cylinder had a big wear gouge but really everything else was pretty good.

So a few weeks later and a bit of expense more the bored .030 machine started up and runs great! No better feeling in the world- like winning the lottery.Wish I could find the guy who sold it to me and thank him, he has contributed hours of unfettered joy.

Kind of off-topic, but maybe one of you guys who are familiar with casting techniques can enlighten me on the reason for what looks like a fabric pattern imprinted in the the top of parts of the head. I’ve seen it before, I believe, on one of my Toyota heads, but I can’t be sure. Something to hold the casting sand in place? Something to slow oil drainback? And why only in certain areas?

Well now you’ve made me curious. I’ll do some digging…