Hawking for My High School Studebaker: Part 3

Simply sitting behind the wheel of my newly repurchased ’64 GT Hawk, it turns out, wasn’t going to make it roadworthy. In order to properly rekindle my fondest high school memories, I’d have to break out the elbow grease. So what had been done to it in the last 20-odd years since I last owned it? Very little, it seems. The pesky exhaust leaks at the manifold had been rectified, and an electric fuel pump and generic voltmeter were installed. Other than that it was preserved in full, a rolling monument to my dumb teenage self. Follow along as I remedy my own juvenile hackery. (Hawkery, maybe? I dunno.)

The first task at hand: mount up a set of late-’60s Crestline Mark II wheels, already shod in new tires. These were last installed on an old Concord, then an AMX. I figured they’d add a nice, period-correct hot rod vibe to the Stude. Indeed, they looked good mounted. Then I arrived at the car’s front right corner, noticing where a massive chunk had been bitten out of the front drum—large enough for one to catch a glimpse of the brake shoe on each rotation. I recalled the precise moment that the Hawk collapsed upon losing a wheel, sending an array of sparks from the scraping metal that is, I imagine, still sprinkled across the right northbound lane of US-1 near Sanford, North Carolina. Due to my previous missteps, I’ll be finding a new brake drum or better yet, discs. At least for now, I broke two hub pullers, threw on some rear shoes, bled everything (with help), and adjusted the spur wheels to their satisfactory, unassisted standard of performance.

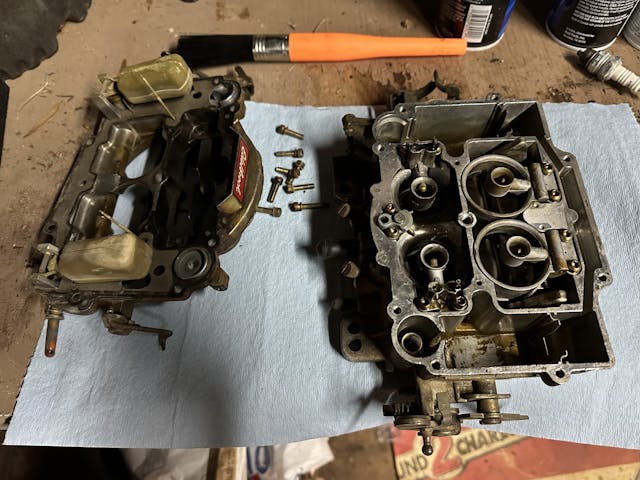

Once tired of addressing problems that made my car neither faster nor louder, I moved on to the fuel system. Yikes. In my defense, I had no part in this horrific fuel pump installation. Breaking out my terminal kit, ratcheting crimpers, and heat gun, I reworked the wiring into something more presentable. The Edelbrock carb still wasn’t having it: the accelerator pump circuit seemed entirely non-functional, and the mixture and idle screws were in complete disagreement.

I suspect the younger Matt Anderson, unfamiliar with the arcane mysteries of the vacuum gauge, is to blame here. Knowing better now, I pulled apart the carb into its smallest pieces, cleaned its nooks and crannies, and reassembled it with components from a fresh kit. Using the assortment of tools now at my adult disposal, I dialed in the carburetor to my satisfaction.

In the spirit of rectifying past sins, I turned my attention to the hose clamps on the rotten fuel lines, as well as the doubled-up fuel filters that looked like they came off a radiator hose. Without admitting to being directly responsible, I can say it possesses my former hallmarks: foraged parts and obvious impatience. Needless to say, I went ahead with all-new hoses, clamps, and a singular filter. I made sure to pump the fouled gasoline into lawnmower cans for my Wheel Horse to consume.

Alas, I knew in my heart that I wouldn’t be able to avoid the wiring department for long. None of the turn signals worked, nor did the brake lights, horn, or reverse lights. (Memories of sailing through state inspections on cool-factor alone came back to me.)

I got started on the most safety-critical functions. For starts, the brake light switch had only one wire on it, and my strategy of propping up my iPhone to shoot video from a fence post indicated that only the left lamp was functioning. While I was replacing the bulb (to no avail), I noticed that the reverse light bulbs had been removed. In their place were permanently illuminated reverse lamps. Then it dawned on me: When I swapped the Powershift auto to Borg-Warner overdrive in the heat of summer in 2002, I had committed crimes of the reverse-light-switch variety and bailed myself out by removing the bulbs. Stupid kids. Someone after me must have come up with the “fix.”

After lots of probing with a multimeter and alligator leads, I determined that the real problem with the brake light was the turn signal switch! Off came the steering wheel, exposing an indicator and canceling mechanism that appeared to be installed either by a thumbless animal or, more likely, by me after school. With a heat gun and pliers, I managed to straighten out the whole mess, bringing the signal switch contacts into their correct positions and the blinkers and brake lights into working order. At the same time, I noted that the wheel had been torqued down on top of the horn wire, which seemed to explain the non-functional horn.

Oh, how naïve to think that a self-generated wiring problem was going to be that simple!

Upon testing the horn, I found it to be non-functional. Replacing the horn and fixing the steering wheel wiring did nothing. I traced the hots and grounds back to their origins, which wasn’t easy given my past wiring misadventures that involved changing the wire color no fewer than three times. More 11th-grade than automotive-grade work. The ground to the relay, which should be switched by the switch at the wheel, was permanently grounded to the bolt holding the voltage regulator down. My mistake. So, with the circuit doubly earthed, why didn’t the horn blow all the time? Beats me.

In laying recumbent beneath the dash, I also sussed out why the speedometer wasn’t working and why the mileage looked eerily … familiar. I do vaguely remember getting annoyed at the rodent-esque racket it was making, which led to disconnecting it at a rest stop on the way to Wrightsville Beach. I decided to just leave it for now.

With my past transgressions acknowledged and somewhat addressed, why not drive it to work tomorrow? The next morning, I made sure my wife was available to rescue me just in case. She agreed but saw fit to remind me that I am, mentally, still a high schooler.

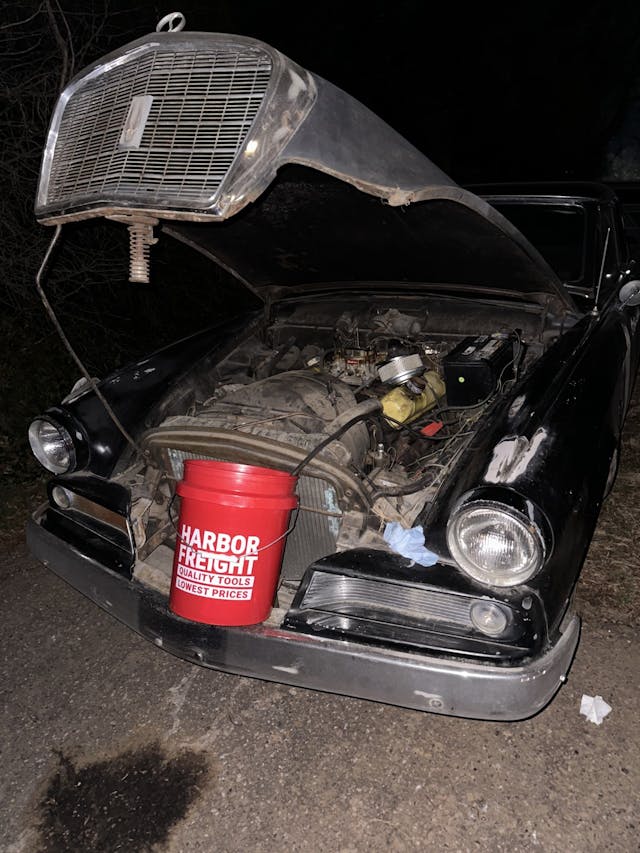

Loaded up with my lunch, laptop, access badge, and tools, I hit the road. My first hint that things might not be right? Total lack of power immediately upon exiting the driveway. As we’ve established, I’m still the same idiot from 2004, so I continued along anyway. Maybe it was just cold, I rationalized. It didn’t take long—about 0.75 miles—before the universe caught up to my false confidence. The Hawk sputtered to a halt in the parking lot of a fried fish joint. I popped the hood to begin diagnostics, at which point the radiator core urinated on my khakis and dumped a quart of coolant on the ground. I picked up the phone and dialed.

“Hi love … whatcha doin’?”

I made sure to ask my wife to please grab a gas can, just in case. As you may remember, all of my jerry vessels were recently filled with stale sludge. Five gallons of it didn’t help. I gave up after it blew backward through the fuel filter and limped the car home to my foundry storage, with my wife following in her 4Runner. I grabbed another car and went to work, sad.

Following my day at the office, Dana and I took a stab at bringing the Hawk the half-mile home. The failure had all the telltales of a fuel sludge problem—likely due to the elimination of fuel filter #2 and its rejected particles sitting on top of fuel filter #1—so I pulled the needle valve filter assembly on the side of the road. “Ok, turn the ignition on,” I asked my wife. Exceeding the call of duty, she fired the 289 right up. With fuel gushing everywhere at a steady idle, I did the most productive thing I could think of; with needle valve and filter assembly in my left hand and my thumb over the 5/16-inch garden hose on the right, I pressure-washed the cruddy parts clean and jammed the fuel hose down the carb while I reinstalled the filter assembly. Dangerous, yes, but I did have a fire extinguisher and precious few cranking amps left.

It was enough to get the car home. Now, with the Stude in my driveway and the radiator off for a re-core, I felt an odd sort of nostalgia amid the thrill of a real breakdown on the way to somewhere important. It really does bring back memories!

Whoever put those wheels on the LS400 needs whacked with a pool noodle, that aside, its always good to get back to where we came from, automotive or otherwise

This makes all my memories of high school/college hackery come flooding back. Thankfully, those old cars weren’t cool enough to live much past my ownership and likely won’t come back to haunt me.

It DOES make me feel better about how long I’ve spent this winter doing all the repairs and wiring on my Merc correctly though.

Enough dilly dally, BRING ON THE FOUNDRY ARTICLES.

Oh don’t you worry! Foundry articles in the queue!

As much as I liked most of my early cars, I’m pretty sure I’m happier NOT to have to revisit all of my adolescent “fixes” and enhancements.

Great that Dana is so on board with your adventures.

Sometime an update on this car that is a week or so of her documenting what is happening from her perspective could be an amusing read for us…

You want her to be honest or just amusing, snailish? 😉

Reminds me of when I decided to install a pair of those cheap amber colored foglights on my 1976 FIAT 2-door sedan that I was trying to transition from a boring econ-box to something that resembled a rally car.

My first mistake was splicing the power for those foglights into the parking light wiring. Shortly thereafter the fuse kept blowing. So what did I do? What any clueless high schooler would do, put in a larger fuse.

One morning as I was about to head to school, I noticed my parking lamps were on, even though the car wasn’t running and the switch was off.

Fiddling with the headlight switch got them to go off. That is until one day, driving down the highway with my parking lamps (and by default fog lamps) on, thinking I looked all cool, smoke started rising from under the dash.

Long story short, I found that the wiring heated up (due to the higher amp fuse) and started to melt and fuse with the rest of the wiring harness.

So what did I do? Again what any clueless high school hack would do. I partially dismantled the dash and started peeling apart melted wires. Instead of replacing the harness, I just cut away sections where the insulation had melted and spliced in new sections by twisting the ends together and wrapping them with electrical tape. Who knows if I even used the proper gauge or if I kept the same wire coloring.

Nonetheless it all held together until a couple years later when it met it’s demise when I proceeded to T-bone a late ’70s Delta 88 that made a last-minute left in front of me in an intersection.

I of course regret selling my ’62 GT Hawk back about 1980, but it was the crummy B-W automatic, and that for me is/was the kiss of death. Four-speed or no speed! Now I could buy it back for 10X what I received, but won’t. It still only has two pedals, though it was a very good handler and fairly economical. It’s best feature, some 45 years gone past, however, was how a white, stock, good original condition GT dressed up my driveway! One of the best Hawk seats was my lawn chair, just admiring the Loewy/Burke/Stevens lines and details. Superb! Hope you don’t keep yours in the ‘rat’ category. Wick

Cars is getting there. It’s good to see your wife is on board for the insanity, that way you are only half insane since you get to share it.

You are fortunate to have such a supportive wife. But I can’t quite tell if she’s laughing with you or at you?? (Either way, laughing is good.)

Now, please tell me there’s an unseen jack stand holding the rear axle up as you’re working on the brakes? And you aren’t trusting the floor jack alone?

This is the biggest case of karma I have ever seen. Awesome as most of us, with the benefit of hindsight and more experience, get to say I should have done this to fix the problem we last saw when the car was sold. You get to fix the issues.

Keep plugging away