Ferrari’s latest one-off is a Spider-slash-show pony

Ferrari’s Special Projects division has delivered another one-off for a one-percenter.

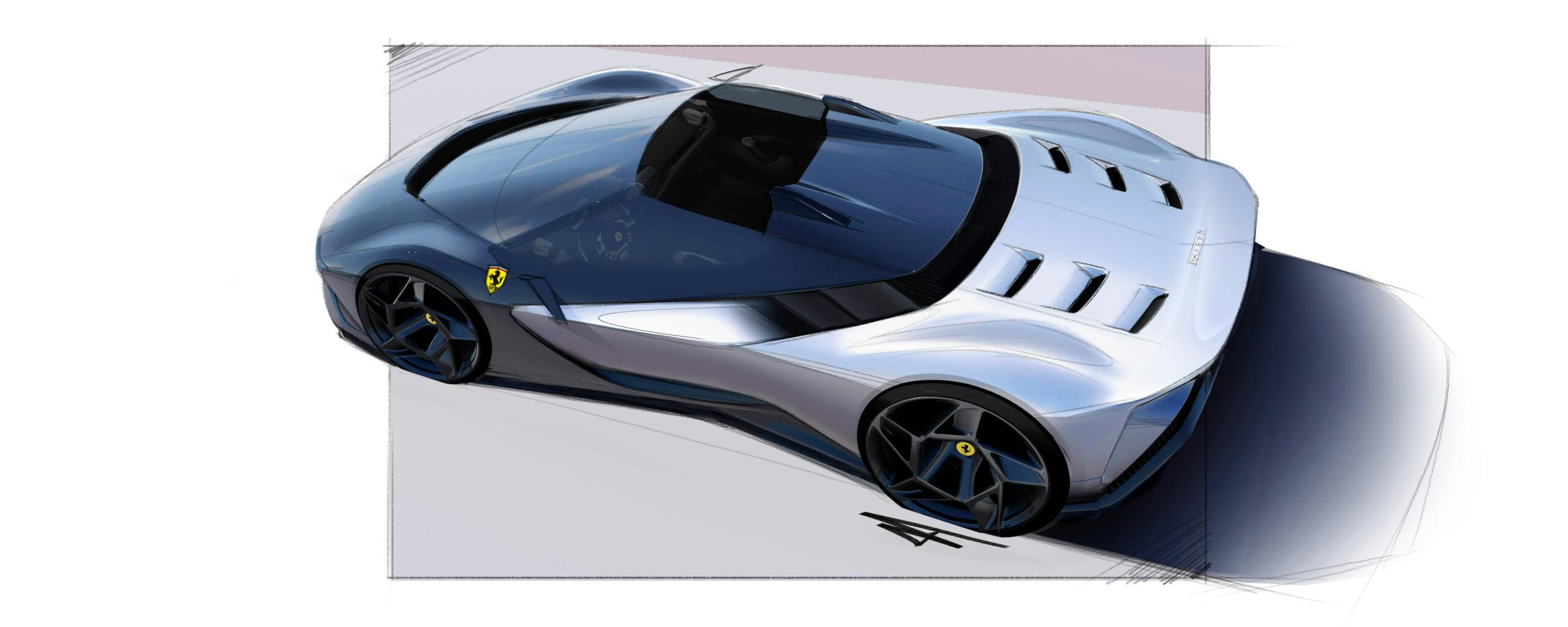

The SP-8 is based on the underpinnings of an F8 Spider, but has been re-bodied in a completely roofless design. Removing the retractable hard top gave Flavio Manzoni and his team at the Ferrari Styling Center the freedom to rework the entire rear section of the car for what Ferrari calls “a full volume with a taut belt line.”

There’s a new full-width grille that’s a one-piece aluminum casting, redesigned headlamps with unique masks and lenses, plus tail lights derived from the Roma, and fetching five-spoke wheels which evoke those fitted to the F40. The exterior finish is a mix of Blu Scuro Stellato paint and raw carbon fiber

Although it may not initially appear to be a radical re-work, it still required CFD simulations, wind tunnel and track testing to optimize the aerodynamics of the SP-8.

Inside, the center console has been fettled with a modified shift gate, and the blue Alcantara seats feature laser-etched details and yellow leatherwork.

Ferrari’s One-Offs are typically inspired by individual customers who come to Maranello with an idea. It then takes an average of two years for the car to be developed, so patience is required. The SP-8 was commissioned by a customer in Taiwan who doesn’t appear to be in a hurry to drive it at all and will be on display at the Ferrari Museum until March 2024.

***

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

Not feeling the wheels.

I humbly submit a correction: Aluminum is not cast from a ‘piece’, it is cast from a molten bath likely in a dry sand molding process in this case–the tooling is relatively cheap to make a few castings to make sure you get a good one. Ingots of aluminum alloy are the ‘pieces’ that are melted.

We appreciate such a modestly-toned correction! 🙂 But seriously, thanks for this and we have adjusted the article accordingly.

It looks allright but that color combo does not do it any favors.