California’s EV West to race at Bonneville with electric streamliner

EV West has made a name for itself with its electric-power conversions of classic cars, but the California shop has also broken into the world of motorsports. Past projects have included experimental electric race cars, with the firm’s Artic Silver BMW E36 M3 lighting the internet up with its silent hand of horsepower pushing the modest time-attack car up Pikes Peak in 2012. This year, EV West’s sights are set on Bonneville, with ambitions to chase the “Floating Mountain” across the Salt Flats in a quest for the E2 class record of 213.084 mph.

This Bonneville-bound streamliner will be one of EV West’s most involved builds yet. Since its early days with the M3, the company has become one of the premier EV conversion companies in the world, building upon its motorsport experience to ensure that its road-car conversions live up to their owners’ dreams. Now, with a decade of wisdom in his back pocket, EV West owner Michael Bream and his mad team of fabricators and engineers are pouring their efforts into the newly-dubbed Electraliner’s chassis, suspension, and EV driveline capabilities.

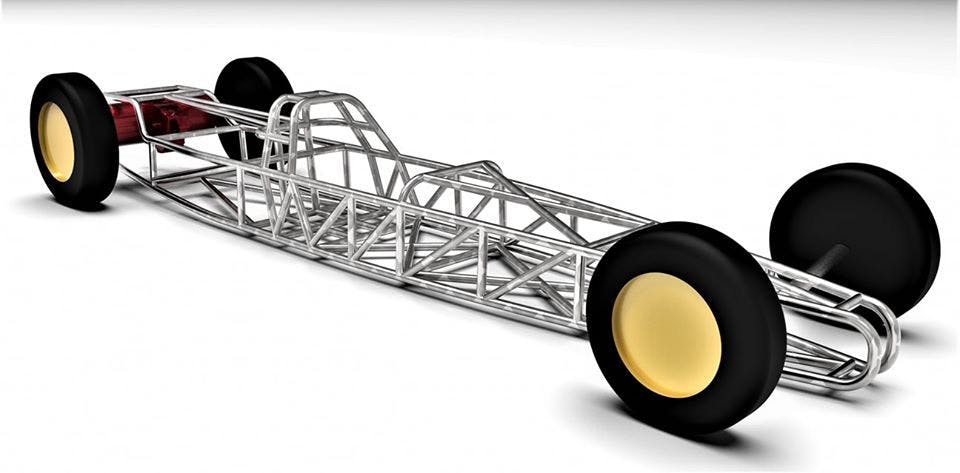

First, the whole car was 3D modeled to ensure that EV West could fit everything into the slimmest package possible. Primary concerns were that the Tesla drive unit, batteries, and driver had enough wiggle room. With the basic model dialed in, it could be sent off for fabrication to Roger Hickey (who is also the aforementioned driver) and Hickey Speed. While Hickey turned the 3D model into a massive 1:1 foam mock-up of the body for laying up carbon-fiber, the EV West team began bending, trimming, and welding sticks of 4130 chromoly together to form the tube-chassis.

The front suspension will use a solid beam axle, like a typical hot rod, mounted semi-solid to the chassis through massive polyurethane bushings. The only articulating suspension will come from the De Dion axle, which acts like a solid axle in its shared motion by both rear wheels, but keeps the Tesla drive unit affixed to the chassis with the original half-shafts meeting the De Dion axle. The unconventional setup provides good roll stiffness and gives just enough compliance—an inch or so of travel according to Bream in a podcast with The Smoking Tire —to ride out the salt crust at over 200 mph.

Powering the modified Tesla drive unit will be 294 of Panasonic’s modular prismatic lithium-ion cells for a total capacity of 37 kilowatt-hours (kwH), which will fit into blocks of 14 units that will stack together in the TIG-welded aluminum battery pack made from 3/16ths thick sheet, each weighing in the neighborhood of 600 pounds. Three packs will be built for the assault on the salt, lifted out of the Electraliner with a mobile gantry system before being charged by solar panels. The nominal output of 357 volts is within the same range as the factory Tesla drive unit, but with its re-geared 4.5:1 final drive ratio, the theoretical top speed has been increased to 337 mph with the motor at its 16,000 rpm rev limit. EV West worked with Quaife to build the unique gear set, as the factory Tesla’s 9.73:1 final drive ratio limits it to around 155 mph in the Model S.

To control everything and manage the intensive data logging that EV West will need to handle while developing the Electraliner, the ECU gurus at AEM have joined the program with their new Vehicle Control Units, which manage the motor controllers and translate the driver’s inputs into brute force. The AEM VCUs allow EV West and Hickey to manage the exact power curve that the throttle will deliver, with the option for wheel- and GPS-speed-based traction control. Despite the lack of an engine, the high-voltage powertrain still requires a cooling system, and this is the one place where EV used a traditional solution: a five-gallon moon tank with as much ice as she’ll take to keep the reservoir cool.

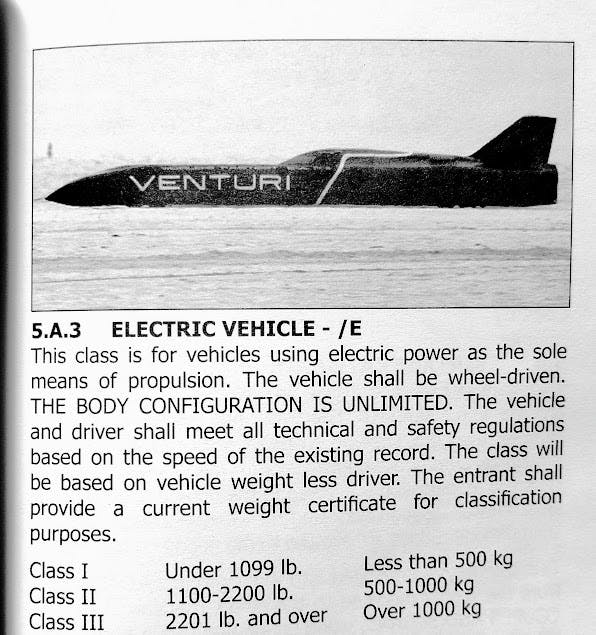

They’re gunning for the E2 class record, which is defined by the vehicle’s intended race weight of approximately 2000 pounds with the driver. The prior record was set by the Rannberg’s Lightning Rod, a pioneering EV streamliner that essentially wrote the rulebook on the class. Ed Rannberg was the first to break 200 mph in 1996 with an electric streamliner, an obsession that grew out of a chance ride in a friend’s EV-converted Renault Dauphine, but he would miss the ultimate record that Lightning Rod achieved after he passed away in April of 1997 in the lead-up to targeted 213.084 mph run. Eric Luebben would pilot the Lightning Rod to its two-way average record average during the World Finals in October of 1997, securing the two-way blast that a failed motor had stopped Rannberg’s 1996 attempts from completing in the FIA-required one-hour turnaround time. By comparison, the lead-acid powered, Lightning Rod is a hammer compared to EV West’s scalpel, but the barrier is still one to take seriously, and EV West intends to work up to speed slowly as the vehicle proves itself on the salt.