Cadillac Racing’s Bespoke LMC55.R V-8 Is All Business

Cadillac’s beautiful, sleek LMDh race car has been tearing up the track at endurance events around the globe, racking up plenty of podium finishes since its racing debut in 2023. While the car’s cutting-edge design is gorgeous, many of us at Hagerty wanted to know what was behind its blistering performance, so we sought some background information on its rowdy V-8 powerplant.

We got to speak with Adam Trojanek, the lead propulsion engineer for Cadillac’s LMDh (Le Mans Daytona hybrid) entry about the development of the LMC55.R V-8. Without revealing too many secrets, he shed some light on the engine and the team’s decision-making process as the raucous V-8 came together.

Trojanek has spent his entire automotive career with GM, taking a job on the performance small-block V-8 calibration team after getting a bachelor’s degree from Kettering University. After that, he spent four years as a program specialist on Chevrolet’s IndyCar team, before rotating into a role in engineering for production engines, where he led the small-block development team on the dyno. Back in racing once again, Trojanek put his V-8 expertise into the unique dual-overhead-cam 5.5-liter V-8 that provides the performance and soundtrack for Cadillac’s successful endurance racer.

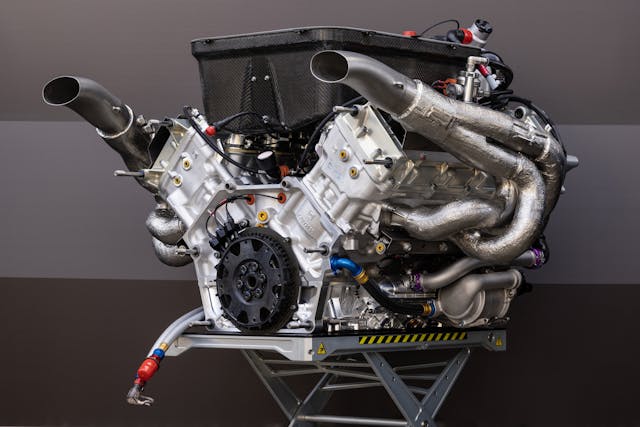

The first thing we got out of the way is that the LMC55.R isn’t the same V-8 used in the Corvette C8.R. “The only thing that we share with the GT3 motor is the fact that it’s 5.5 liters in displacement,” noted Trojanek. The deeper you dive in, the more you’ll find to back up that sentiment.

“For this LMDh/GTP car and for the hypercar rules we live under . . . we all have to meet a specific power band that’s based off a declared maximum engine speed that we refer to as an nMax,” said Trojanek. The race series measures that power using torque sensors on the axle. The propulsion development team had to keep in mind that the engine would have a hybrid assist, but Trojanek and the rest of the team wanted the engine to be able to provide the necessary power on its own so that the driver could count on the output, “regardless of ambient condition and regardless of fuel strategy.”

Cadillac’s race entry didn’t turn out to be a naturally aspirated V-8 by accident—many options were on the table. Cadillac’s competitors use turbocharged V-8s and turbocharged V-6s with less displacement, but the engine had to be true to the brand. “The engine is easily identified as a Cadillac . . . the best way to do that is how it sounds,” said Trojanek. That made the decision for a naturally aspirated V-8 easy, but they still had to make it perform at a high level.

“One benefit, for sure, is that we have no turbo lag,” explained Trojanek. “That’s one reason why we didn’t go with turbos—because we knew that whatever the driver wanted, it would be there, instantly, or nearly instantly, compared to a turbo.” Of course, a turbocharger also means more moving parts, more plumbing, more weight, and additional cooling demands. Rather than worry about all that extra mass, packaging it, and tuning the right boost curve, the Cadillac team could spend time improving other aspects of the car.

“I think the propulsion system allows every OEM, including Cadillac, to make a unique experience for fans and for drivers. It’s turning into a kind of software war in terms of how we control the propulsion system to meet what the drivers request and need.”

—Adam Trojanek, Cadillac LMDh Lead Propulsion Engineer

“There are always opportunities to find more power and more efficiency with a new engine versus something that is already homologated,” said Trojanek. “We took advantage of that.” The team focused on ways to increase combustion efficiency and reduce frictional and pumping loss. One way to eke out extra efficiency is by squeezing the intake charge using a high compression ratio. An efficient combustion chamber is a must, and direct injection is another big factor that helps sustain a higher compression ratio. We asked about the specifics of the compression ratio. “I can’t say, sorry. It’s high,” Trojanek added with a laugh.

Variable-length runners and swapping intakes based on track configuration are not allowed, so tuning the intake was critical. “ITBs (individual throttle bodies) are a good choice for a naturally aspirated engine just in terms of allowing good throttle response. They also allow you to tune as you see fit for the ultimate power curve, as well as allowing good low-end response for transient conditions getting off the corner,” said Trojanek. ITBs let each intake runner breathe from the atmosphere, and placing the throttle bodies close to the cylinder head improves throttle response. If you’ve ever driven a car with a huge intake, like a tunnel ram with a lot of plenum volume, these things are the opposite. Because it’s at the top of the engine, any additional mass in the intake would raise the center of gravity, so engineers went through a lot of work to ensure the intake system was as light as possible, while still being durable.

“What we call ‘pens down’ in terms of we’re snapping the chalk line,” Trojanek said, was mid/late 2021. That’s when they started building the parts they’d been designing. “Our first engine was running on the dyno in Q1 of 2022.” That’s a fast turnaround. “We had about a year of in-vehicle and on-dyno development before homologation during Q4 of 2022.”

Trojanek said the engine is a structural member of the car. “That drove us to utilize a lot of advanced materials and design practices so that we could be as light as possible but as strong as possible while also maintaining durability and reliability for the engine, since it is an endurance series,” said Trojanek. “‘To finish first, you must first finish’ that’s always the mindset.”

He told us that the engineering team tried to limit how many times a component was split into multiple components. That helps with strength and weight, and it can also reduce the number of fasteners needed. Every bolt is added mass, and a bolt can’t work itself loose if it’s not there in the first place. The team employed that mindset on construction throughout the car, but the biggest pieces of the engine are an excellent example. The top half of the block is cast from a high-strength aluminum alloy, but the sump half is billet, machined from a single piece of aluminum. The block and sump are machined together, as a matched pair, with the bottom billet piece carrying the main caps and acting as a main girdle to add rigidity to the bottom end of the V-8.

Other ways of minimizing mass included employing the best methods of 3D printing currently available. “That really allowed us to explore different materials that might not be available outside of additive manufacturing,” said Trojanek. Nearly 30 parts designed for the engine are built using additive manufacturing, including the oil tank and the oil cooler shell both printed in sintered aluminum. Some of the parts 3D printed for the cooling system would be very difficult to fabricate using traditional methods while also minimizing flow restriction within the packaging constraints of the engine bay. In many cases, 3D printing is quicker and also produces a lighter part.

“We knew the goal we had to hit, we knew the timeline to get the job done, and we pushed like mad until we got there.”

—Adam Trojanek, Cadillac LMDh Lead Propulsion Engineer

The team also did its homework when building the engine’s dry-sump oiling system. “We drew upon a lot of our other GM racing engines and families to help guide us in the latest and greatest technology that was on the market,” Trojanek said. “We ended up with a configuration that offered that best pumping efficiency, scavenging efficiency, and was also the lightest-weight option on the market at the time.” The dry sump scavenges oil from six locations in the engine: one in each bay of the block that houses a pair of cylinders, with two additional pumps that pull oil from elsewhere in the engine. Trojanek wouldn’t say specifically, but it’s important that oil pumped to the top end of the engine makes its way to get recirculated, so you can guess that it’s from either the cylinder heads or somewhere in the valley of the block. “We use DLC (diamond-like coating) on various components to help with wear, but it’s not as much as people would think,” Trojanek said. “The engine is very reliable and has good wear, because we did our work ahead of time to make sure that we didn’t necessarily need the DLC.”

Besides a high-speed flyby, the best way to experience the Cadillac V-8’s signature sounds is to hear it leaving the pits. “We have a strong enough electric motor to give us, honestly, really good 0–60 times,” noted Trojanek. When he says 0–60, he’s talking kilometers per hour, as 60 kph is the pit lane speed, governed by the series. Time spent getting up to the max pit lane speed is wasted, and penalties for exceeding the limit can also cost the team. Cadillac’s strategy seeks to eliminate those inefficiencies. “We can achieve that quicker, smoother, with the appropriate amount of energy to the tire to get up to speed, a lot more accurately than we can by slipping the clutch in an ICE engine.” Once the car leaves pit lane, an electronically controlled clutch manages the blend to internal combustion power. That’s when the engine snorts to life.

The results speak for themselves. “Everyone recognizes the Cadillac sound,” said Trojanek, especially the characteristic roar it makes as it leaves pit lane under EV power and fires up the V-8 in an instant.” It’s won the hearts of many, and terrified some,” he joked.

We asked Trojanek if the team experimented with different exhaust configurations besides the four-into-one arrangement that made it onto the car. “You look at how small our headers are and the exhaust system as a whole. To fit a Tri-Y into that added unnecessary mass. We didn’t really need it to make the power or the torque curve. In terms of efficiency, it was kind of negligible. The four-into-one is what suits us best,” Trojanek said.

GM’s host of engine development tools enabled engineers to simulate exhaust tubing lengths to try exhaust options virtually before any actual tubing was bent, or printed, in this case. Each of the collectors is made from 3D-printed Inconel. There weren’t any surprises turning the combustion calculations into a high-flowing reality.

We asked Trojanek if Cadillac’s engineers placed any Easter Eggs into its parts, like logos or emblems hidden in castings. “No, we talked about it, but I think we were just so focused on making sure that all the performance metrics were met.” Casting a Cadillac logo into parts was a topic of discussion. When you’re sweating fastener size and fastener material looking for every gram you can, it’s tough to justify extra aluminum mass that’s not making the car any faster. “The exhaust is our easter egg!” Trojanek joked.

We also asked about any nicknames the engine or car had during development. He won’t outright say that the engineers nicknamed the prototypes “Batmobile,” but Trojanek did admit that the test cars were black and the propulsion system software that powers the cars has a customizable background where the engineers have placed an image of a very recognizable 1990s movie car. If a buttoned-up Bruce Wayne drove a CT5-V Blackwing, it’s not a stretch to imagine the Caped Crusader prowling Gotham in Cadillac’s sleek, low-slung race car.

Cadillac put its bespoke V-8 to good use in 2023, capturing the team and manufacturer championships in IMSA GTP/DPi. The 2024 racing season is going well, too, as Cadillac is tied for first early in the IMSA WeatherTech SportsCar Championship season.

You can see the cars in action on track and hear that famous Cadillac V-8 sound all around the world, but you can also bring it into your living room with the documentary No Perfect Formula, which premieres May 31 at 7 p.m. ET and takes a look at the team’s 2023 Le Mans effort. You can find it on the Hagerty channel #2545 on the Samsung TV Plus app on Samsung Smart TVs, Galaxy Devices, and on the web. If you’d like to watch it on any other device, you will also find it on Hagerty’s Facebook page.

***

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

Cadillac isn’t mean for racing nor do they know how to build an actual racecar or race motor. Stick to building luxury cars as you are out of your element here caddy.

I watched Cadillac place third at LeMans last June. The 100th running of LM, it was a packed field with many applicants turned away.

So Greg, you been away for the past 70 years?

Cool looking car and very cool engine. Too bad none of this gets seen in a modern Cadillac. Where is a 5.5L DOHC V8 for the blackwing cars?

Pure Mindset!

I’ve always found the kind of trade offs made for peak efficiency and balancing a true race only car to be one of the most interesting aspects of cutting edge technology cars. A small loss here can be a big gain there. This will produce more horsepower but resulting in a higher center of gravity and…those things as mentioned that end up being tenths of a second on the track. You always want to hope that effort filters down to production models even if slowly and in small increments. Hearing GM has this program in house helps to reinforce the idea that racing improves the breed