Why Ford had to paint the GT350R wheels black, and 4 other carbon wheel secrets

Carbon fiber can be a dream material. It’s light, it’s strong in tension (how hard you can pull it before it comes apart), it can be shaped many different ways. But it can also be a nightmare, as many competitive cyclists are all too keenly aware. Certain stresses on a carbon-fiber/epoxy composite can lead to “explosive delamination” which is pretty much just what it sounds like. It can be deadly in a 50mph downhill mountain bike run. Is that really a risk you want to take at 180mph on a racetrack?

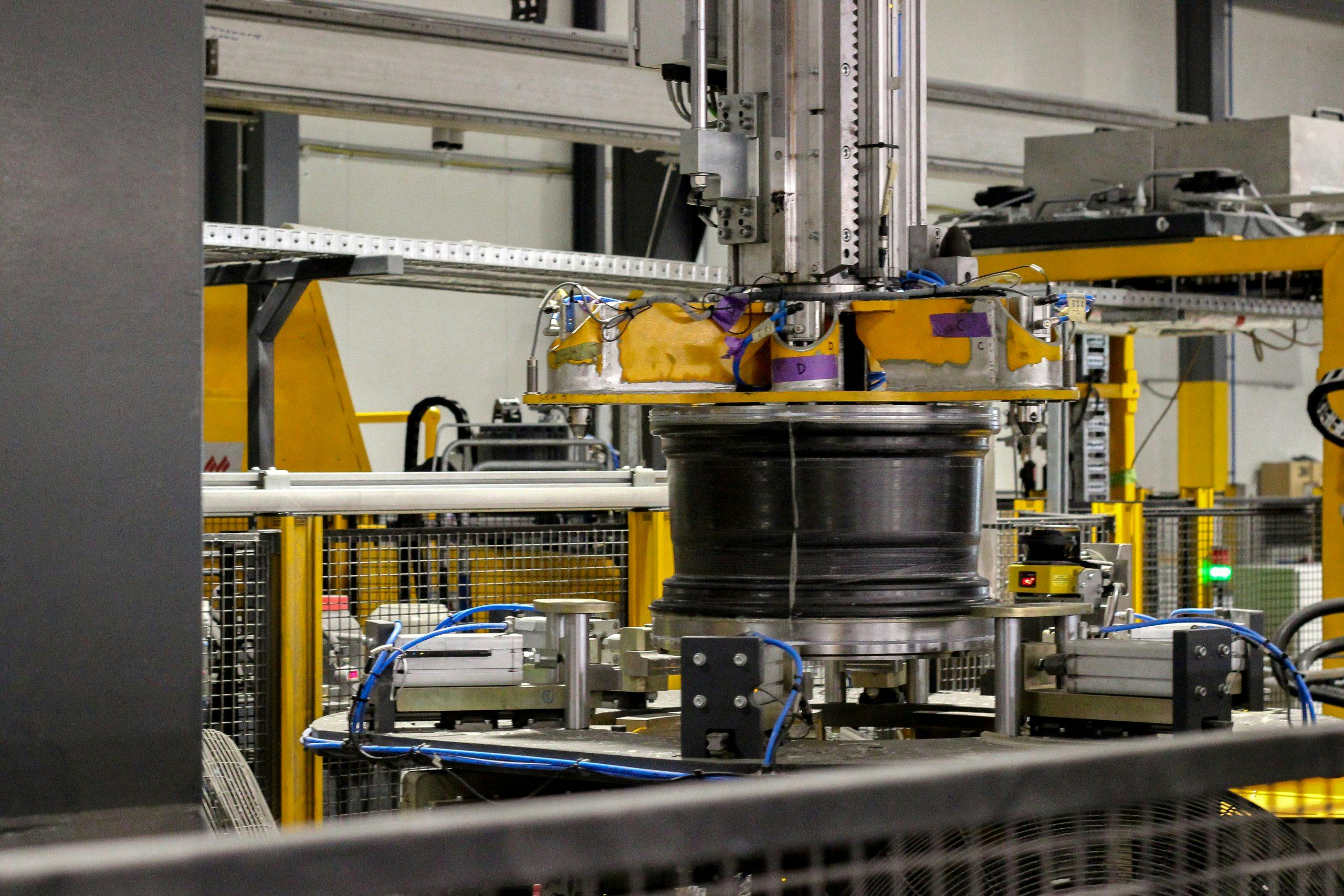

To find out, I sat down with Carbon Revolution founder Ashley Denmead for a brief but productive interview. As you probably know, Carbon Revolution makes the ultra-trick wheels that are currently turning heads on the GT500 Track Pack. (They’re suppliers for Ferrari as well). Mr. Denmead didn’t know that we’d already conducted our own carbon-fiber durability test of sorts, making our human crash dummy Kyle Smith repeatedly hit curbs at high speed in a new GT500 until we all got bored of waiting for him to die and decided to do a comparison test instead. Nor did I mention it. Instead, I asked a zillion questions about carbon-fiber durability, putting the most surprising insights together below.

Secret #5: The GT500 wheels got something that the Ford GT wheels don’t.

Carbon Revolution supplies wheels to the Ford GT Heritage Edition as well as to both recent Shelby Mustangs. Since the GT is the fastest of these and has the potential to develop the most cornering force, you would think that the GT’s wheels would be the most highly “engineered” of the group. Turns out it ain’t so.

What we call “carbon fiber” is usually a composite of two materials. The carbon fiber itself, long thin strands of an immensely strong material, and the resin that gives it a shape plus a certain amount of compressive strength. You cant stand on a string of yarn, and the same is true for carbon fiber. The resin lets you stand on it. Much of the development done in carbon fiber over the past few decades has been related to resin, which is usually where the problems crop up. In particular, resin is sensitive to heat. It’s possible for the modern generation of carbon-ceramic brakes to develop 1000 degree temperatures — and that’s Celsius!

The massive weight and speed of the GT500 meant that its wheels were going to be exposed to massive heat loads, so Carbon Revolution fits a special thermal barrier to the inside of GT500 front wheels. This coating reflects 100 degrees’ worth of heat and keeps the wheels out of the danger zone. But the Ford GT is lighter and better-balanced front-to-rear, so it doesn’t work its front brakes nearly as hard. That means there’s no need for a thermal barrier.

Secret #4: Even if you do manage to overheat a carbon fiber wheel, it’s not Doomsday.

Carbon Revolution and Ford have both tested their wheels to duty cycles beyond anything they believe a GT500 (or Ford GT) can produce in real life. When you get the wheels way into the hot zone, at temperatures the brakes can’t even generate, what happens? The epoxy in the wheel barrels softens and… the tires slowly begin to lose air. Kind of anti-climactic, if you ask me.

Secret #3: They’ve never cracked a wheel barrel all the way through.

There’s a reason that Carbon Revolution wheels aren’t as fragile as, say, the first generation of carbon-fiber downhill mountain bikes: they’re wrapped a hundred layers or more thick in high-stress areas, up to a quarter-inch thick. This is the same amount of layering used in an F1 safety cell, or in the McLaren MonoCell crash structure of its street cars. “We’ve never seen a crack go all the way through a wheel barrel,” Denmead notes. “Explosive delamination is something that just doesn’t happen with our wheels. If you hit them hard enough, you can damage them… but the worst part of that is just the cost to replace the wheel.”

That being said, it is possible to repair a Carbon Revolution wheel that isn’t too far gone. The company has a Stateside repair partner that can replace damaged layers and refinish to factory specifications. Once that happens, the wheel is as good as new; unlike aluminum wheels that start developing microscopic cracks the minute you put weight on them, carbon fiber wheels shouldn’t show any degradation over time.

Secret #2: Carbon Revolution would like to put your daily driver on its wheels, cheaply

Right now, all of Carbon Revolution’s wheels are made in their Australian factory. But Ashley Denmead isn’t unaware of his geographical proximity to the world’s primary source of OEM and aftermarket wheels. “We have 50,000 wheels out there. That’s 12,500 cars. So what we’re doing is disruptive, but on a small scale. We have to go larger to do more, and that means alternative sourcing and production.” Since a reduction in wheel weight pays so many dividends, from acceleration to fuel economy to ride quality, there’s pretty much no vehicle segment that won’t benefit from using carbon wheels. It’s just a matter of cost. Speaking personally, I hope that Denmead comes up with a way to do it cheap in his home country, the way Swatch figured out a way to do Sistem 51 in Switzerland.

Secret #1: Why can’t you see the carbon fiber weave in the original GT350R carbon wheels?

It didn’t really have to be that way. Carbon Revolution’s original plan for the GT350R wheels was to have them display the same gorgeous and perfectly bookmatched carbon-fiber weaves that you can now see in their GT500 wheels. But Ford had a concern, and that concern was ultraviolet light. Eight years ago, the resins used by Carbon Revolution in their wheel construction weren’t completely UV-proof, meaning that they could be weakened over time by sunlight. This problem wasn’t unique to Carbon Revolution; it’s why so many bicycle manufacturers painted over their carbon fiber frames during the Nineties.

Ford made the call that they wanted to paint the wheels opaque, to protect the resin. “It was a disappointment to us,” Denmead admits, “but Ford didn’t choose the wheels for how they looked. They made the choice based on performance, so they didn’t feel a need to show the weave. Needless to say, Denmead’s crew went into high gear testing new UV-resistant resins. Today’s GT500 wheel is just as light as its GT350R predecessor despite being larger. And if you’re that rare madman who doesn’t garage his GT500 24/7, you can let the wheels soak up the sun.

There’s no getting around the price and rarity of Carbon Revolution’s wheels, but having driven the GT500 with both aluminum and carbon running gear I think there is a legitimate, tangible, and desirable difference in favor of the big-ticket rolling stock. I suggested that Carbon Revolution immediately get cracking on some carbon wheels for a Radical SR8; Denmead noted that he got his start in Formula SAE, building carbon-fiber wheels for his school team’s race car, but didn’t offer any reassurance beyond that. In the meantime, if you want a new car with the latest and greatest, and you don’t have an order in for a new 2023 Z06, it’s going to (still) be Ford vs. Ferrari!