Project AT1: Turning a barn-find bike into a minimum viable product

“It ran when I parked it.”

If you don’t roll your eyes at that, you’ve never tried bringing a vehicle that received this treatment back to life. The slow, cruel hands of time conspire with the corrosion to wreak havoc on idle components that were designed for well-greased motion. I’ve walked this road many times and my latest adventure went exactly as I knew it would (but had hoped it wouldn’t). This barn-find Yamaha AT1 was indeed riddled with issues—but it has reached the “minimum viable product” phase.

In other words, I’ve spent five evenings toiling over the machine to see whether it is even worth trying to return it to a running state, let alone a rideable one. From the first inspection to the most recent garage poring-over, I concluded that the AT1 seemed to have good bones.

Then I tried to make it run.

Remember, I am looking to reach “minimum viable motorcycle.” I’m not taking apart anything that doesn’t require it, or futzing with pieces to solve problems that might exist. I’m doing only what is needed to determine whether this motorcycle is a lost cause … starting with the brakes. The front-brake cable was not frozen, and squeezing the handle provided some stopping power while loading/unloading the bike from my van. The rear told the same story, providing some friction while rolling into the garage.

Brakes, check.

Next up: electrical. There were loose wires everywhere, including a couple that were heavily abraded and frayed. Upon close inspection, nothing represented a fire hazard, though. I grabbed the spare 12-volt battery that hangs around the shop just for occasions like this and connected the terminals. Hair and motorcycle remained unsinged. I turned the ignition key. Lights came to life, allowing me to use a multimeter to check whether electrons were flowing to the right places within the ignition system.

Hello, hiccup number one.

Want to guess the problem here? You get three tries, and the first two don’t count.

The points were corroded to the point of failure. (You’re a good mechanic for someone reading articles on the internet.)

There is a little corner of my toolbox that holds the tools that I don’t use often but which I don’t want visitors to move. This is where the ignition files live—the tiny planks of hardened steel sized just to fit between the contacts of a points set and remove the corrosion and pitting so they will allow the coil to build and discharge voltage properly.

Scuff scuff, turn key on, open points and see a faint little spark jump as the first separate.

A sign of life!

I drained, inspected, and replaced the oil. Same story as with the spark plug. While the cylinder was open, I took the opportunity to put some light oil in the cylinder before trying to turn the engine over for the first time. Usually when doing this on a long-stored motorcycle—this AT1 sat, or rather marinated, for at least 13 years in a fairly damp environment—I prefer to shift the transmission into second gear and use the rear wheel to turn the engine. This process reveals any odd noises or resistance while removing the temptation to simply kick harder on the kickstarter, which could cause more problems.

Success! The piston took right to its vertical dance as if it never stopped, and the transmission shifted through its gears without suspicious behavior. Turning the rear wheel with my finger over the spark-plug hole blew my finger off with decent gusto. (A proper compression gauge would give you a number over which to fret, but if the cylinder will blow your finger off the spark plug hole, you have enough squeeze to run.)

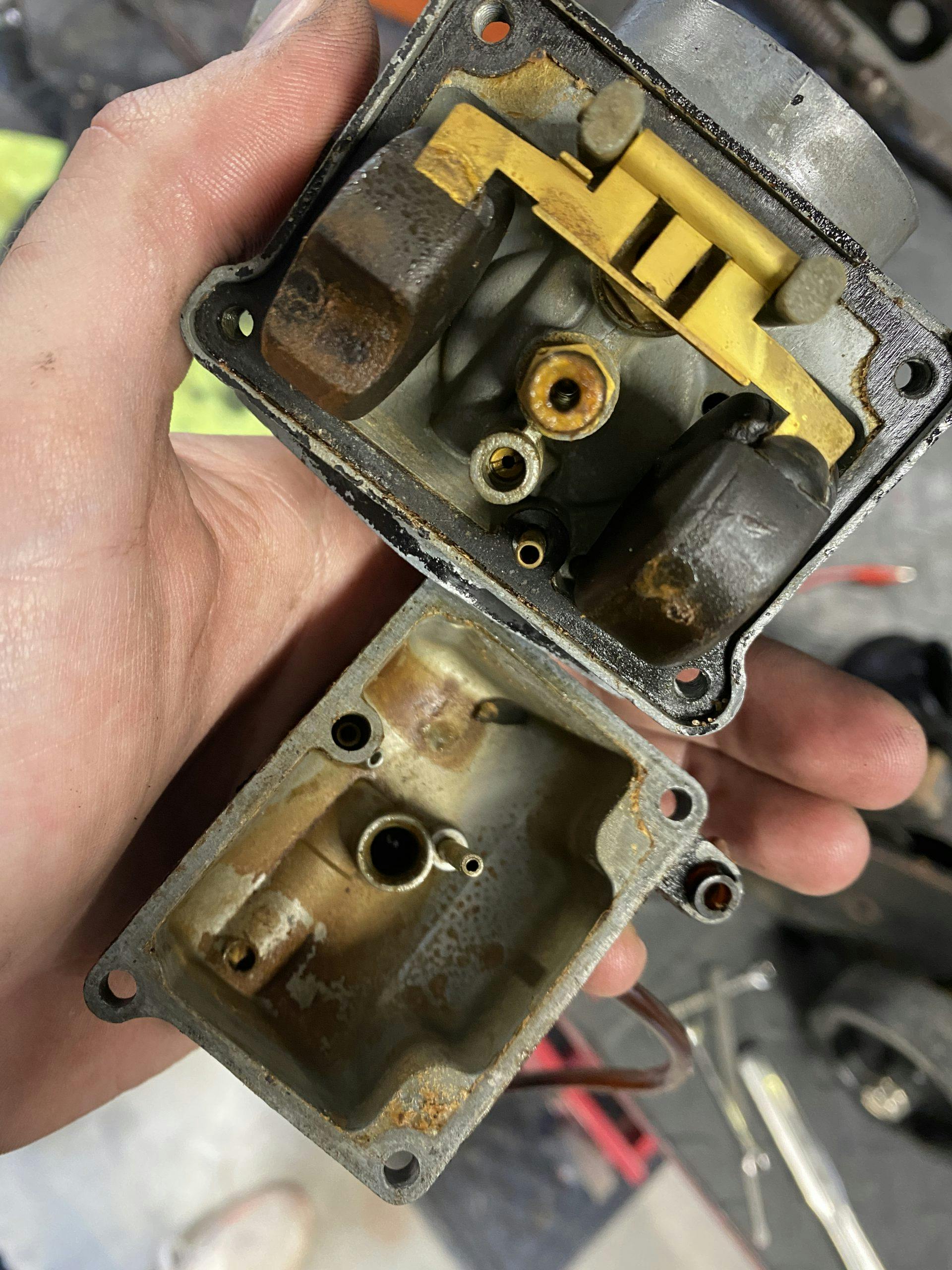

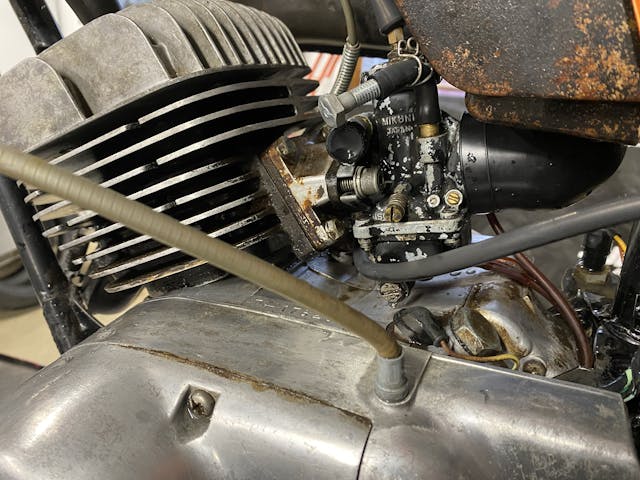

That leaves us at fuel. The gas tank didn’t look too bad, but remember, we are trying to do the absolute minimum here. Gas tanks aren’t required. Carburetors are, unfortunately. This Yamaha has a pretty simple Mikuni carb, but this particular one had a slide that was stuck in place. After removing it from the bike, I carefully applied some carburetor cleaner so it would seep around the slide and, hopefully, free it. Sadly, I had to resort to prying on the slide—extremely carefully—to get it to move.

(This method is extremely unadvisable and should be used only as a last resort, with the assumption you will damage your slide. I got lucky this time, which puts me at 50/50 odds over the last 10 years.)

Of course, the rest of the carb didn’t fare much better. A quick spray of carb clean, a blast of air from the compressor, and lubrication with some two-stroke mixed gas as everything went back together had the slide snapping shut like it should, the floats holding, and fuel flowing. (I used a small squirt bottle filled with gas to fill the float bowl. That’s plenty of fuel to get an engine started and that’s all I was after.)

Finally, time to kick the thing over. And kick. And kick. And kick. And kick? Everything was lined up. The dominos should have been falling. I grabbed another spark plug and tested for spark.

Nothing.

I filed the points again. A nice white spark jumped the gap. A few more kicks and cough from the exhaust. Another break, rechecking the points and even testing the condenser. A third try, and the engine cycled 5 to 6 revolutions before falling silent once more. Just enough to puff smoke out of the exhaust.

No strange noises when it did, though. Spark was intermittent at best, which forced me to remember that Yamahas of this era are quite demanding in the electrical department. These bikes need robust batteries to start and run reliably. My small backup 12V likely didn’t have the juice that the AT1 wanted.

No matter: The AT1 has qualified for minimum viable product. Here, I would safely declare a project worth working on, readjusting any goals or timelines according to my findings—but this is also the point at which my time with the AT1 ends. This bike is owned by a mechanically savvy friend who hasn’t worked on motorcycles and who simply wanted to make sure he had a good starting point before diving in. I’m going to loosely reassemble everything and ship it back to his garage with a list of recommendations based on my experience and knowledge. He’ll handle the rest.