Piston Slap: Steps to avoid cross threading the Courier?

Victor writes:

Sir, you were very helpful to me before, and I hope you will take the time to shed some light on my latest issue.

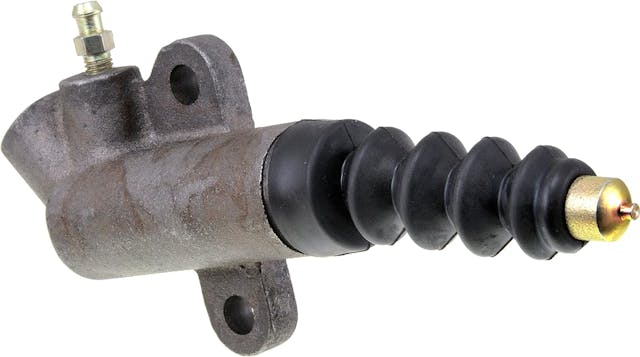

The slave cylinder on my 1979 Ford Courier, four-speed with the 2.0-liter engine, started leaking. I ordered a replacement Lux brand slave cylinder, but when I attempted to thread the hydraulic line to the cylinder it would start to thread on but then bind up. I was very careful to make sure I was not cross-threading it. After numerous attempts I tried screwing the line back onto the old slave cylinder and it threaded on. Thinking that maybe the threads were bad on the new cylinder I sent it back to Parts Geek and ordered a Dorman slave cylinder. Exact same thing happened; it would only screw on partly and would then bind up.

I have looked at the threads on the supply line and do not see anything wrong with them. I was able to order a rebuild kit and will attempt to rebuild the old slave cylinder and see if that works.

I am not a mechanic, and my level of ability is mainly limited to changing the oil, filters, coolant, and spark plugs, but I did think this was a job I could handle. Thank you for your time.

Sajeev answers:

Hello, Victor. Thank you for reaching out; I am happy to help. This absolutely sounds like something you can do, provided the part was actually manufactured like the original bit from Ford/Mazda. I have a feeling that the best move is to ship your old slave cylinder to a place like this and have them rebuild it. You might have a hydraulic shop in your city that can also do the same service, and it’s always great (and convenient) to support a local business.

I reckon there is a manufacturing error on all these new slave cylinders, and there’s only one factory in China making them for all brands. Or perhaps there was a design change over time, and the automated system online isn’t letting you buy the right part. You can try ordering multiple cylinders at a part store too; they will be happy to help. But I think getting yours rebuilt might be the best move. Tell me what you think.

Victor replies:

Thank you for the quick reply and advice. I will send the slave cylinder off to the company you recommend and have it professionally rebuilt. Would it be a good idea to start and run the engine every so often while the truck is sitting with the slave cylinder off?

Sajeev answers:

Running the motor in the meantime is certainly not a bad idea, but there’s no need to do it. Depending on the age and formulation of the gasoline in the tank, a vehicle can sit for many weeks while you wait for the new part. I can keep my cars sitting around for months (not by choice), so keep that in mind.

Let me be clear on one thing, however: I do NOT have experience with the company I referred you to. I just wanted you to know such places exist. You should look into multiple vendors across the internet, maybe use this link to find one. I’ve said it before, and this question proves it, the Google “near me” search is absolutely crucial if you own a classic with limited parts support. (You know, not a Camaro, Ford Truck, Corvette, etc.)

Have a question you’d like answered on Piston Slap? Send your queries to pistonslap@hagerty.com—give us as much detail as possible so we can help! Keep in mind this is a weekly column, so if you need an expedited answer, please tell me in your email.

***

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

It has been so many years since I saw one of these. We had one we drove to school.

The symptoms sound like a thread mismatch – perhaps attempting to thread a standard fitting into a metric bore. A lot of parts suppliers will attempt to build one part and use it in as many applications as it will fit. Since 90% of applications these days are metric, I would bet your slave cylinder has metric threads.

One option would be to take your line and cylinder to a hydraulic shop and have them tell you what the threads are – and maybe even supply you with an adapter. Going this route will solve the problem for today as well as the future – especially since aftermarket parts aren’t what they used to be

Great advice, TG. 👍

Wow, yes, the adapter is a fantastic idea! Thank you for sharing.

Option B would be to go to a local NAPA store and see if they have a tube nut that fits the replacement cylinder. Then, you would know exactly what the thread pitch is. Do the same thing with the original and then get the correct adapter. Our shop would cut the original hard line, install the correct tube nut and re-flare the line. Did that once or nine times…

Another fantastic idea, thank you for chiming in!

Thank you Sajeev and everyone who offered their advice.

I did determine that the original cylinder was metric, and when I compared the old release cylinder to one of the new ones it was obvious that the pitch of the treads were different. As a last attempt I ordered a fourth release cylinder from eBay, the seller had recently purchased the inventory of an auto parts store that had been closed for 10 years. The new release cylinder and my supply line had identical threads and it installed without issue. I then bled the system and now my clutch is up and working again.

Thanks again,

Victor

Hooray!

It is sad we can’t necessarily trust our cheap Chinese knock off parts to work. Hopefully a rebuild will fix it.

I forgot about these things. We drive one to school. Most rusted away like the Luv trucks.

It’s not the Chinese parts manufacturer, per se’, it’s the “interchange” that says the part will fit. Especially the inter manufacturer cars, like Ford/Mazda. My Datsun roadster is standard fasteners, but the other Datsuns like a 510 were all metric. Bear in mind the 80s GM built in Mexico, the engines are metric and the bodies are standard . Or is that vice versa… I am lucky enough to go to parts store that have and uses the old parts books. More than once the part in the computer isn’t the same as the one in the parts book.

My 79 Cadillac had metric fasteners on the body and standard on the drivetrain

Ford had to stamp “Metric” on the transmission pans because the engines were still standard but the transmission as well as body fasteners were metric. Confusing times.

I put probably 100,000 hard miles on one as a work truck in the mid ‘80 to early ‘90 era. Great truck for what it was. Those of you that believe running an engine while the rig is stored or otherwise out of commission are sadly uneducated in proper vehicle car. Put a quality battery tender on it and leave it alone. Of course truly long term storage requires more work putting the vehicle into and out of but most who do are smart enough to do properly.