Keep current with your wiring and connections

Let’s talk about wiring harnesses. These components do not have a glamorous job, and because they do not announce themselves with unseemly clunking noises when they’re going bad, they don’t tend to get much attention. But if you’ve got an aging car in your stable, it is a good idea to think about the state of your electrical system.

The hero in today’s story is my 280-ish-thousand mile 1996 Volvo 850 Turbo. (The -ish comes from the odometer gear having been broken for about six months before I assumed ownership from a friend.) All those miles mean that time, vibration, heat, and moisture has taxed the wires’ original insulation and connections. That’s particularly true of the engine harness, which wraps from the ECU on the inside passenger fender across the front of the engine to the battery.

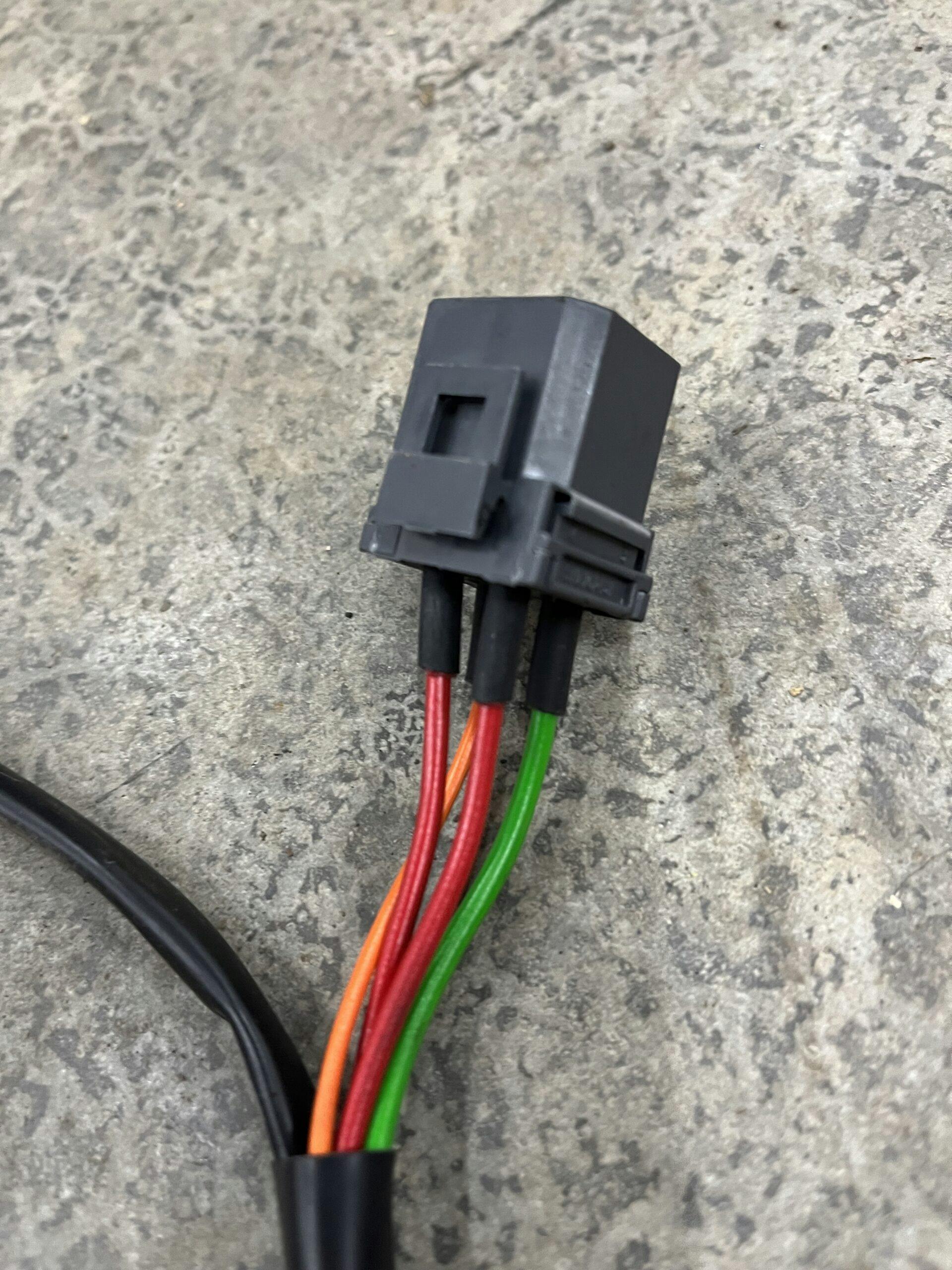

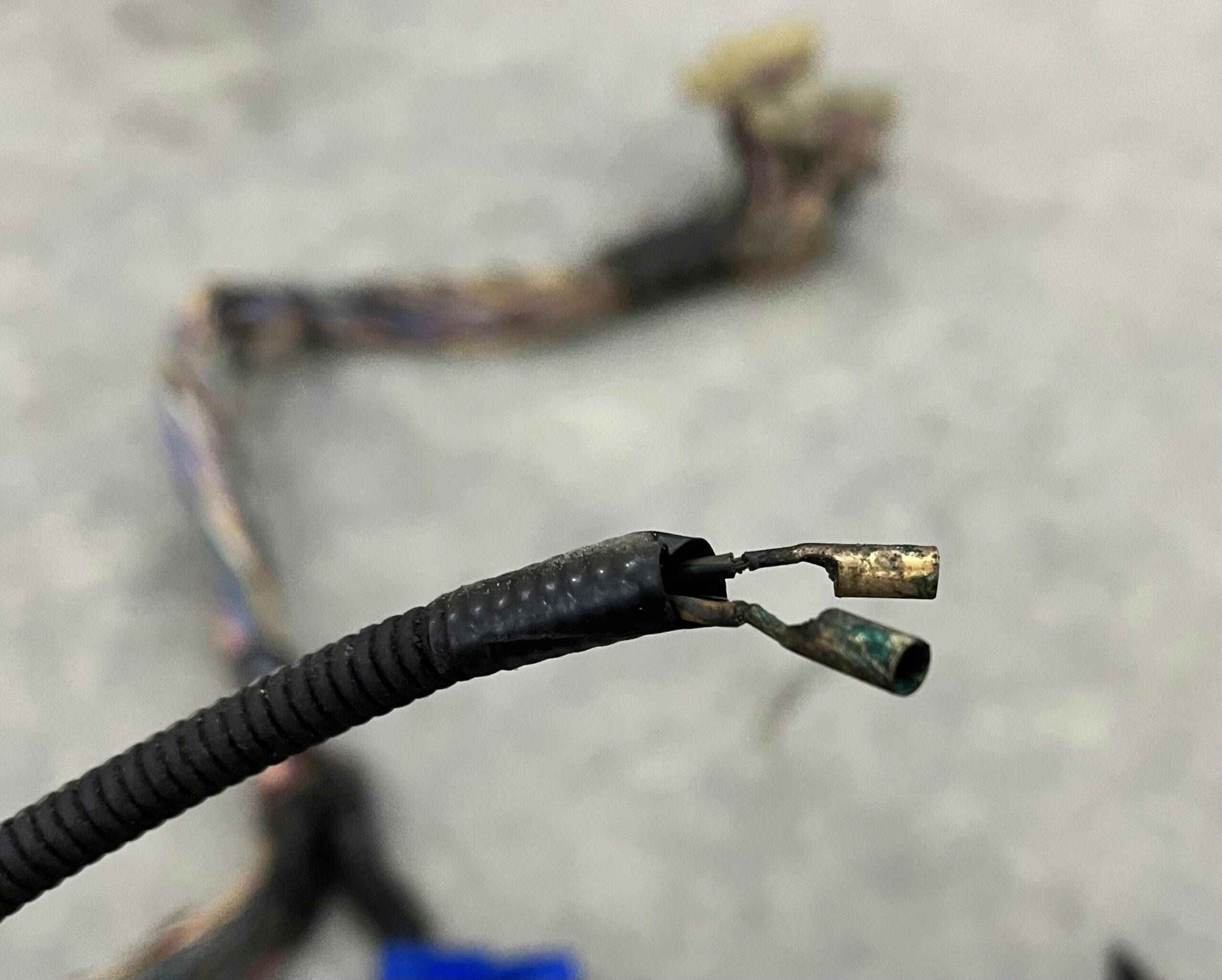

The issues started about five years ago, a couple thousand miles before I parked the car in 2018. One of the four wires headed into the connector for the fuel pump relay corroded apart, and presto, the car would not run. Perched in an easily accessible but comparatively exposed spot above the radiator fan, each of the harness-side connectors for these relays suffered from corrosion and peeling insulation to some degree. Sooner or later, they’d all fail.

As us pre-2000s Volvo owners are wont to, I had a parts car handy. I grabbed the moderately-less-atrophied connector from the spare harness and spliced it in. This was a temporary fix only to hold me over to my next purchase.

Soon after, a new-to-me daily driver (a 2001 Volvo V70) showed up in my driveway. But the 850 wagon had wormed its way into my heart (Volvo owners know), so I decided to keep the old thing. And why not? The massive sway bars and Koni dampers were indecorously fun in corners, and the manual swap I did later, in 2019, woke up the whole experience. 330-mm rotors all around and a larger turbo added to the already decidedly un-wagonlike behavior. The charm was real.

On the other hand, I hadn’t done the car any favors by fussing with its various electrical connections on several occasions. Old wires prefer to be left undisturbed, and moving them can break connectors or cause tiny cracks in dry-rotted insulation. I’ve dropped the subframe twice—once in 2012 to replace the engine, and a second time for the aforementioned manual swap.

Everything worked as intended on reassembly, but seeing how rough many of the connections were, and having made one temporary fix already, I wasn’t confident in straying too far from home. I needed a solution if I was going to continue carving up back roads and occasionally using it as a Swedish home improvement hauler.

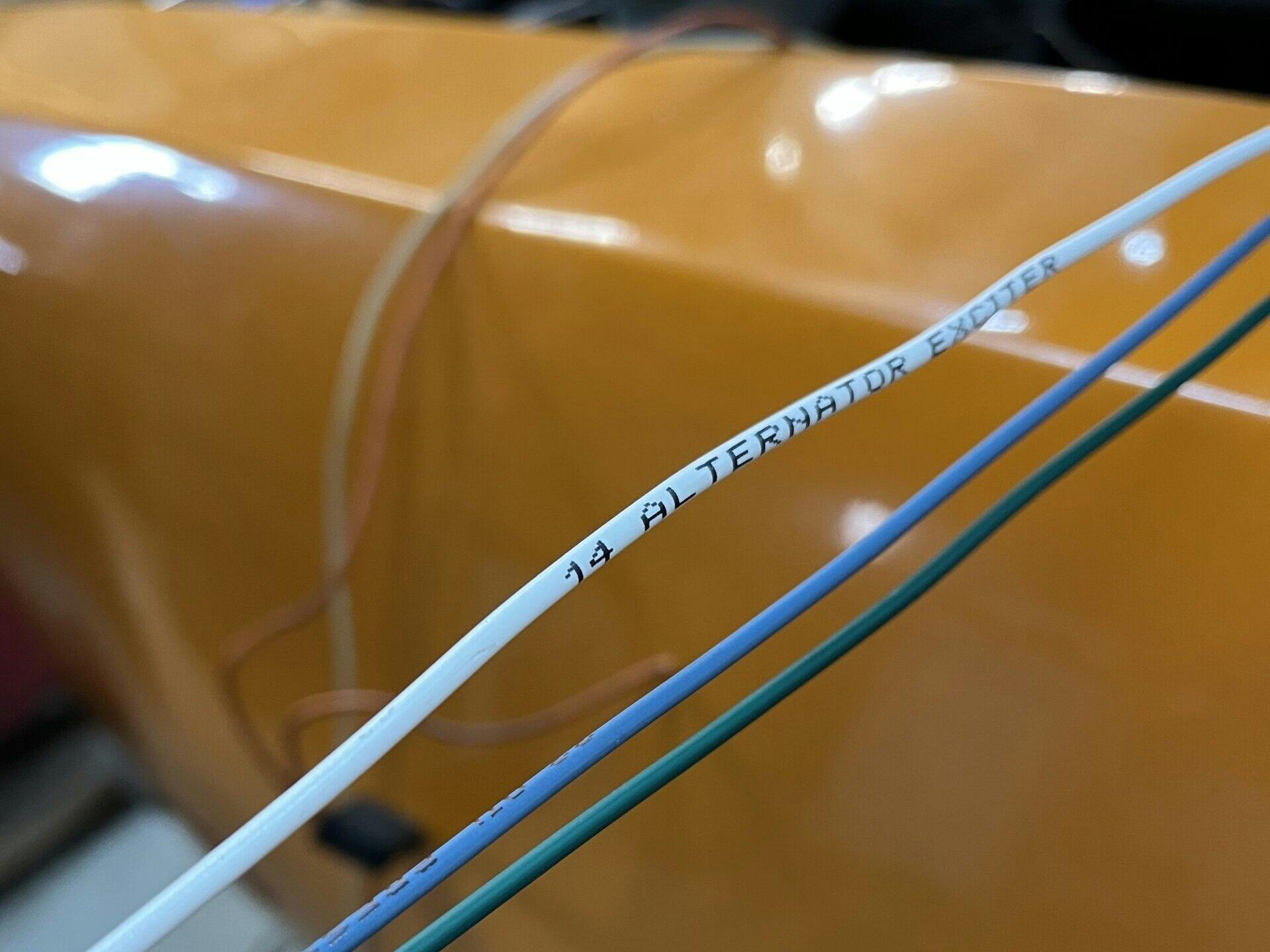

Fortunately, brand-new engine harnesses for the 850 exist. A little bit of searching turned up Dave’s Volvo Page, a website that looks like it was last updated on a Gateway running Windows 95. It’s a proper old-school resource swimming with goodies for ‘70s-‘90s Volvos. The new engine harnesses are made to order in the Netherlands with factory connectors and improved sheathing.

The install was a breeze; everything fit as it should. I took the time to clean up the ground attachment points and attaching hardware to ensure good contacts. Speaking of grounds, I noticed the battery ground wires looked a little worse for the wear, too, so I’ll be replacing those before I button everything up.

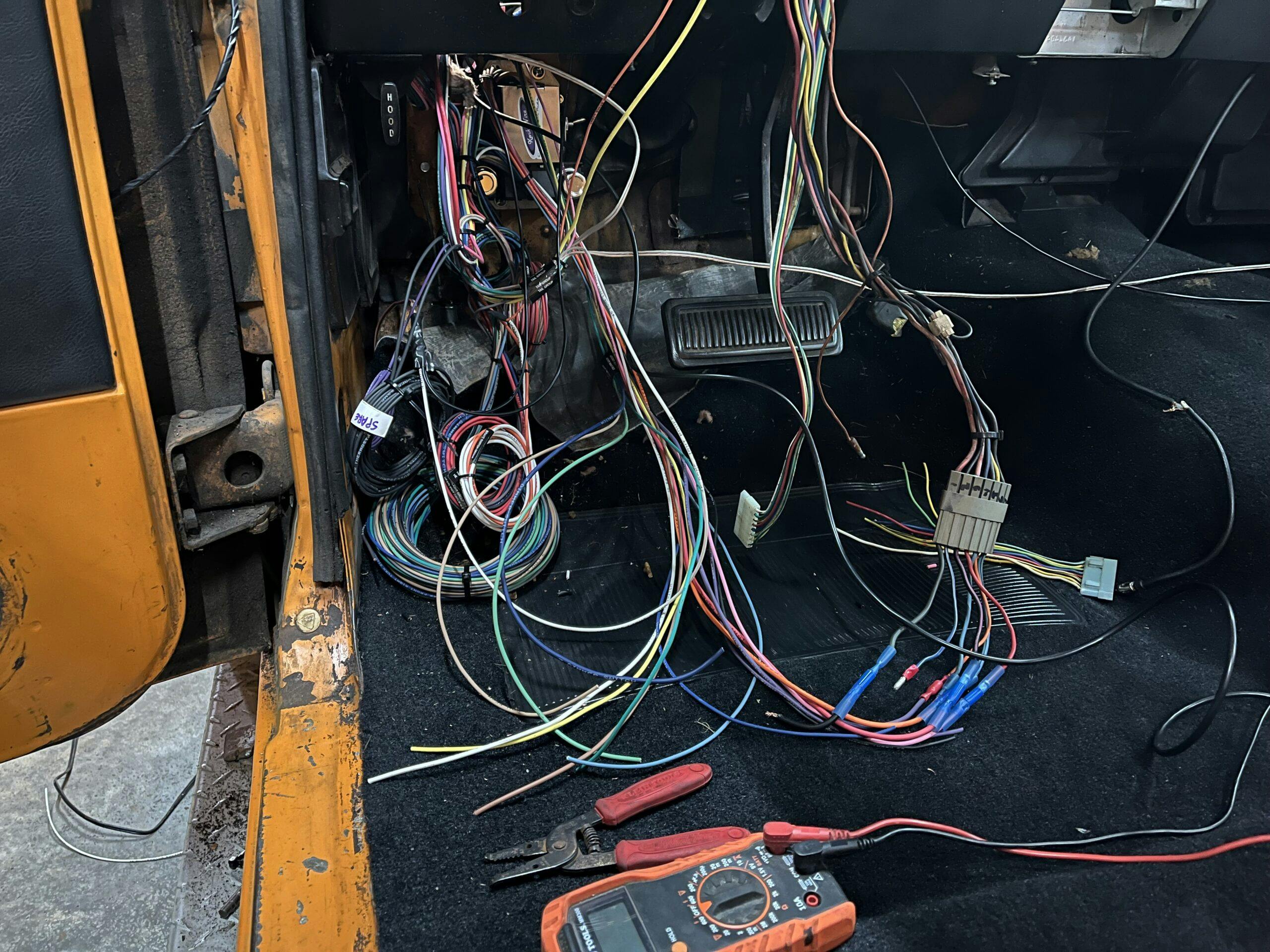

Not every car is so easily repaired or blessed with plug-and-play replacement options. Sitting next to the 850 in my barn is my cousin’s 1979 Dodge W150, also in the midst of a wire transplant project. The truck has given me fits, by comparison. Some new replacement harness segments (for the front lights, as an example) can be found, but there is very a limited supply of quality used harnesses available for other segments. We ended up choosing a universal harness and fuse box so everything would be new. The Dodge now starts, but it’s taken a good deal longer than the Volvo.

Maintaining the electrical system on a collector car is always important (insert British car joke here), but the repair efforts only become more pronounced with time. (We are closing in on 30 years since OBD-II was introduced, after all.) It’s sometimes easier to simply ignore wiring until there’s a problem, but next time you’re under the hood, take some time to inspect your electrical connections. It’s an area worth addressing before sparks fly.

***

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

Years ago, when I was restoring my 1937 Terraplane, I had to replace the wiring harness. Suppliers wanted hundreds of dollars for a harness. The entiere wiring diagram for that car fit on a single page. So I bought some wire, a bunch of terminals, and some fabric loom material, and made the whole harness. I added wires for fog lights and turn signals.

I had so much wire left over that a few years later I was albe to rewire my 1950 Hudson.

For other projects, I figured out how to make wiring diagrams on Excel. It helps a lot to have a record of what you have done if you need to fix anything.

Good advice, Bob. My “homemade” wiring diagrams were made decades before Excel, though. They exist on scraps of paper, cut off box lids, the back sides of product tags – whatever was handy at the time. For some reason, I got in the habit of saving them all, and they take up half-a-drawer in a filing cabinet in my shop. What I wasn’t so diligent about, though, was always including an explanation of what the diagram was for. Diagrams for projects long-gone exist in that drawer, likely to never be used again, even if I can figure out what they are for. [The other half of the same drawer is full of pencil-on-scraps “plans” I drew up for woodworking projects like bookshelves, a Hope Chest for my wife, and even a crib for my Goddaughter 30+ years ago].

Someday, I gotta get organized. Like “scan-all-of-my-old-printed-photos-to-make-them-digital”, however, I doubt that converting the schematics and plans to computer will only remain a pipedream. 🙄

I have a growing collection of terminals, crimpers, and plug-ends as I have discovered the git-r-dun approach to wiring repair generally doesn’t get it done in the long run

I,m a do it yourself and this site will help me alot