Ignition Coil Basics

Even for the somewhat knowledgeable among us, the ignition system occupies an almost magical place in our automotive understanding. A place occupied by the intricacies of the Quasi-turbine engine and the Pogue Carburetor. We understand the principles, but whatever actually happens “in there” is to some degree, confined to our imaginations.

Like an Electromagnet

An ignition coil is basically an electromagnet. It has an iron core with fairly thick wire (primary winding) wrapped around it a few hundred times. There is also a secondary winding – about 200 feet of thinner wire coiled between the iron core and primary winding. This winding lies inside the magnetic field created when electricity goes through the primary winding.

When you switch on the ignition and the breaker points are closed, current flows through the primary winding, creating a magnetic field. When the points open, the flow of primary current stops and the magnetic field collapses. This sends current through the secondary winding. The coil becomes a transformer, stepping the voltage up. If your car uses a 12 volt battery, the 12 volts you put into the primary side of the coil will exit the secondary side as 30,000 volts!

The high voltage is carried away from the coil by a high-tension cable that looks like a short piece of spark plug cable and runs to the distributor tower. With a one-cylinder engine, you could run the coil straight to the spark plug, but in a multi-cylinder engine, you need a distributor to route the high-voltage secondary current to fire each spark plug at a specific time. This is called “ignition timing.”

If your car uses a negative ground and you have a coil with primary and secondary terminals, the primary winding is connected to the terminal on the coil that is marked “+” or “Bat.” This is the terminal that receives voltage from the battery. The primary wire is then coiled around the iron core and its other end is attached to the terminal marked “-“ or “Dis.” The voltage flows from this terminal to the breaker points inside the distributor. (Positive ground is the reverse.)

Failures and Fixes

Most ignition coils are long lasting and reliable, but a weak coil you can be the cause of under-hood havoc. You cannot operate a car smoothly without delivering high voltage to the spark plugs to ignite the air-fuel mixture. Most coil failures result from secondary winding defects. Sometimes the thin lacquer insulation between the two windings deteriorates. Other times the windings are no longer insulated from ground. These kinds of coil problems are usually caused by heat and vibration.

It is possible to have a sudden failure due to broken windings or bad connections inside the coil. However, it is more common for coil problems to show up as hard starting, a repeated high-speed miss or a gradual decline in ignition system performance.

Coils can be tested with an ohmmeter (most coils will give a reading around 8,000 ohms) or with the small scope on a Sun machine. A normal coil will give you a “heartbeat” pattern on the scope, shorted windings will produce a “bumpy L” pattern and open windings will give a flat horizontal line.

All coils with metal housings can be tested for grounded windings by touching one probe of an inexpensive test light on the metal container and the other to the primary and high-tension terminals. If the tester lights or you see sparks, the windings are grounded out and the coil is defective.

Many service manuals recommend temporarily substituting a known good coil for a suspected bad one. If the ignition works properly with the good coil, you will know the original coil was bad. Sometimes coil tower spark leakage or a broken tower can be repaired, but often it’s best to find a replacement coil.

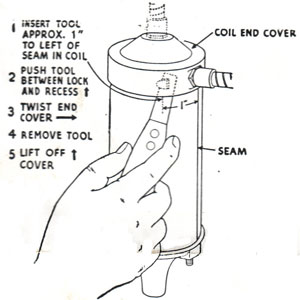

When working with older cars, you may run across lock switch extension coils, an early anti-theft device. The low-voltage wire from the ignition switch/battery to the coil was sheathed in an armored cable to guard against “hot wiring” of the vehicle. For factory-type repair of a lock switch extension coil you may be able to find a swap meet vendor with a coil service package for your car. These come with a full instruction sheet. Many restorers modify the lock switch system by using a conventional coil and routing the hot wire through the armored cable.

Support for these kinds of repairs is readily available. If your car has a Delco-Remy coil, Yesteryear ( ) in Port Charlotte, Fla., specializes in these kinds of parts and may be able to help. According to Wired for Success author Randy Rundle, you would be well-advised to look in the back of hobby publications for companies that specialize in the restoration of lock-switch coils and other ignition parts.

Working on your own car always carries a level of risk. To avoid injury to you or your car, always consult a professional before attempting any repairs or modifications.

John “Gunner” Gunnell is the automotive books editor at Krause Publications in Iola, Wis., and former editor of Old Cars Weekly and Old Cars Price Guide.