How it’s made: ARP bolts

Automotive Racing Products (ARP) started making bolts, nuts, and other fasteners in Southern California 50 years ago. Its start-to-finish handling of every step of manufacturing, from material selection to packaging, has given the company a reputation for quality fasteners that hold up to serious abuse. ARP’s products can be found in everything from Top Fuel dragsters to F1 race cars, 400-mph land speed streamliners, and show-winning hot rods. It is even contracted for specialized fasteners used in aerospace applications.

We were invited to tour several of ARP’s facilities in Ventura and Santa Paula, California, where it manufactures every fastener. Each stud and bolt is forged, washed, hardened, washed again, tempered, and milled before the threads are rolled. It’s a laborious procedure, but each cold-forming process adds strength and gives ARP bolts more clamping power, as well as the ability to withstand far more strain than your average hardware store Grade 8 fastener. Here’s how it works:

1. Spools of wire arrive by the truckload and are loaded in warehouses.

ARP’s process begins with stainless steel and chrome-moly steel wire sourced from around the world. Due to the alloys used, orders are often made three or more years in advance. Regardless of material, all wire is shaved at the mill, removing the outer surface of the steel to eliminate seams and defects. A sample piece from each roll is sent to a third-party lab for a metallurgical test to confirm its composition. Stainless wire is copper coated to prevent sticking in tooling, while chrome-moly steel is coated in molybdenum lubricant.

2. Wire is fed into a cold-forging machine that forms the head and shoulder of a bolt.

This cold header machine is set up to produce a high-volume part. As wire is fed into the machine, the first step is to shear it to length. Next, it moves laterally into a die and is struck with several tons of force to begin forming the head. After three more dies and three more stampings from the machine, out rolls a 12-point bolt head. Hot forging is used for small quantity runs of parts that don’t warrant the laborious process of setting up a multi-stage machine or bolts and studs that are either larger in diameter or longer than the cold header’s capacity. An induction coil heats the wire red-hot, and a single hit from a massive press forms the head in one step.

3. Five steps are performed on the wire, from the initial cut wire on the left to the formed bolt head and shoulder on the right.

While it does use modern CNC machines for some tasks, many of the machines ARP uses are heavy, cam-actuated units purchased at auction that are refurbished with new tooling. These machines from the 1930s and ’40s use large, cast-iron parts that maintain their shape even after decades of use, helping maintain precision in the finished product.

As manufacturing continues in a building next door, parts are first sent through a washer that uses an aqueous solution to remove any oils or lubricants. Then they’re racked vertically to ensure even heating before they’re sent into the internal quench furnace. Inside the furnace, parts are heated in a 100-percent nitrogen atmosphere to prevent contamination. Once they’ve reached the proper temperature for the allotted time, parts are oil quenched internally in the furnace to lock in their hardness.

4. Head studs are heat treated.

Loading them vertically allows each piece to reach the proper temperature throughout.

5. Parts are quenched in oil stored below the furnace. The flame at the door prevents outside air from contaminating the nitrogen atmosphere inside when the door is opened.

After hardening, parts run through the washer again before moving to an oven for tempering. Tempering lowers the hardness of the steel, but greatly improves its ductility (the metal’s ability to withstand tensile stress). Parts go in brittle and come out tough.

Next, parts go into a shot-peening machine, where they’re tumbled and hit with high-velocity steel shot to cold work the surfaces and remove stress from the material.

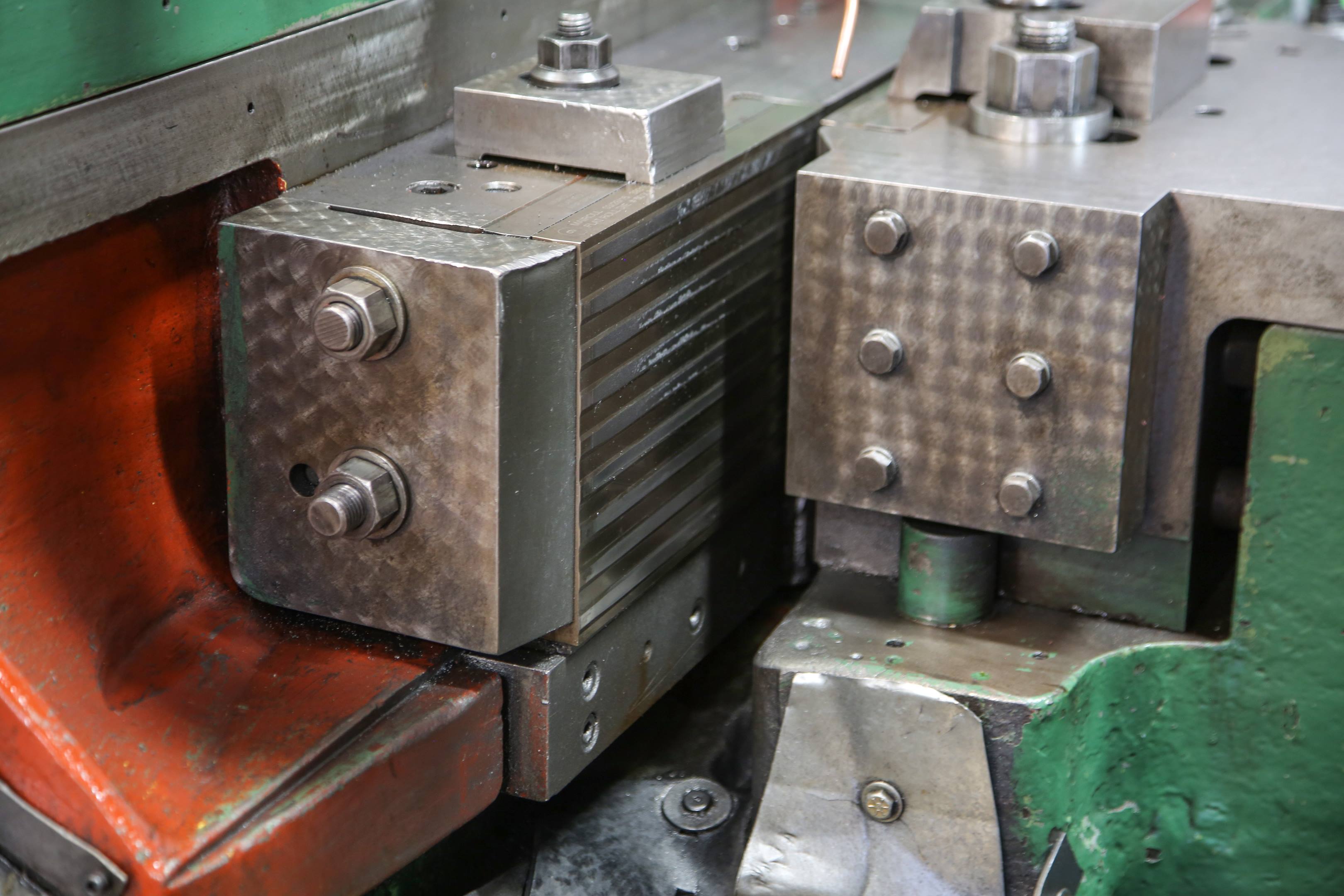

Several processes are aimed at getting the part perfectly straight. First, parts are rolled between two ridged dies—one stationary and one that reciprocates to force the part to roll between the dies.

6. Instead of rolling in threads, the ridged-steel dies of this repurposed thread roller make the parts straight.

7. A close-up of the machine shows the ridges in the die on the reciprocating side.

The rolling leaves a rough shank as the metal is forced to the voids between the ridges. Because no material is removed during threading, the stud is precision-ground to within .0002-inch to leave a perfect surface. An oil bath is used to cool the parts during grinding to allow precision tolerances.

8. Studs are loaded into a grinding machine. Notice the perpendicular marks on the shank of the studs left by the straightening roller.

9. Freshly ground studs have a slightly reduced diameter where their threads will be rolled.

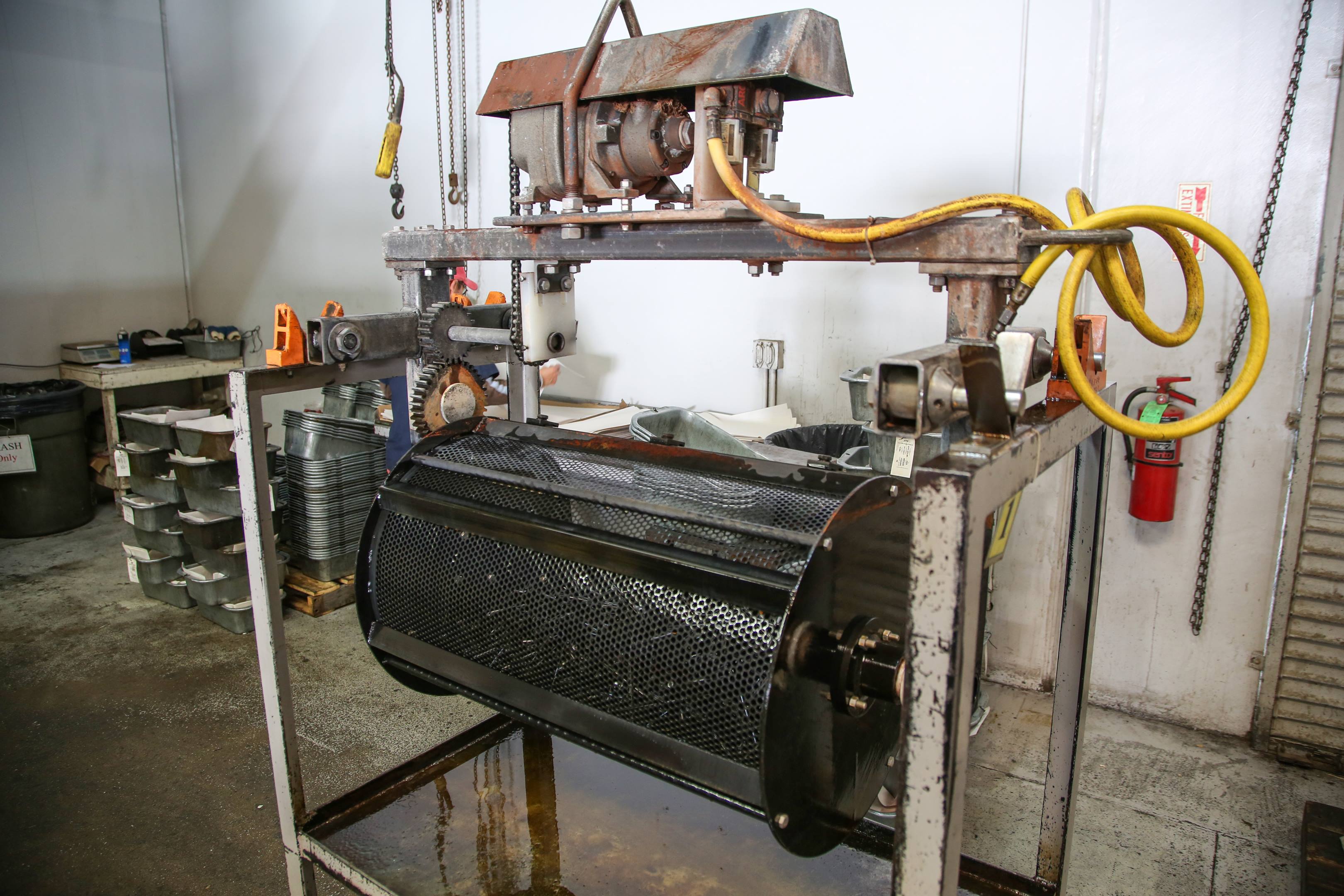

10. The metal shavings from the cooling oil are removed by magnetic rotating drum. Once the oil is pressed out, the metal is sold to a recycler.

In another building, vibratory polishers filled with various media polish the fasteners. Some fasteners, typically stainless steel, get additional wet or dry polishing before thread rolling. Some parts also get polished after thread rolling.

11. Vibratory polishers use progressively finer media to finish the surface of the fasteners.

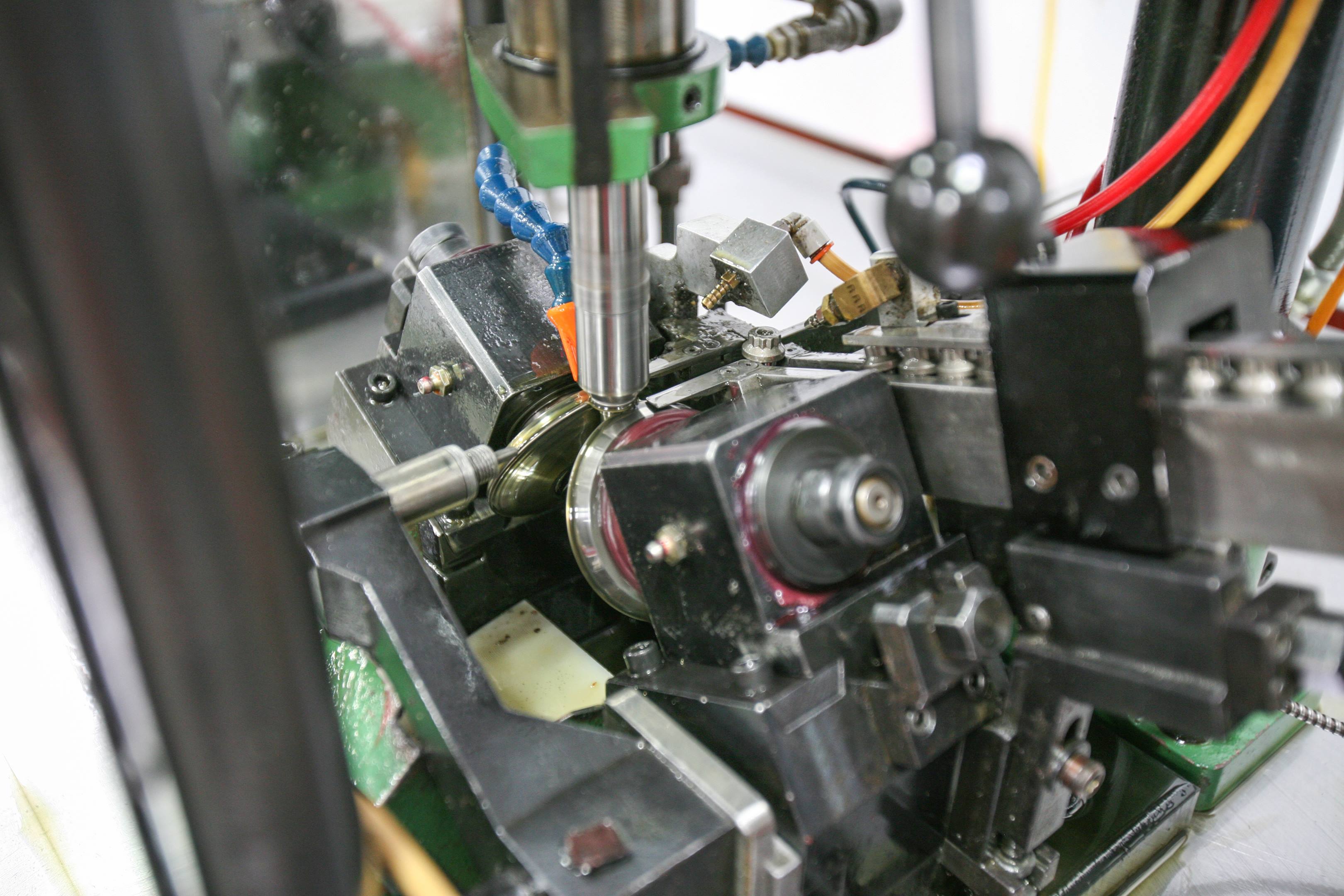

You may have heard of fillet rolling a crankshaft; ARP does the same to the .030-inch fillet under this bolt head. The bolt is spun over two dies as it’s pressed down, applying a compressive stress that increases the bolt’s resistance to fatigue.

12. The two tool-steel rollers press into the fillet under the head, compressing the material giving it greater fatigue resistance.

The final mechanical process is rolling the threads. ARP uses two basic types of thread rollers. One, like the straightening machine we talked about earlier, uses a reciprocating slide to roll the threads between two dies. The other type uses three thread dies to roll the thread. No material is removed, the valleys are pressed into the shank of the bolt, causing the peaks to rise a corresponding amount. This process is completed cold for must bolts and studs, although in projects using steel with a Rockwell hardness rating of about 48 Rc or higher and strengths of 220,000 psi or more, threads are warm rolled, well under the temperature of its tempering, keeping thread hardness more consistent with the rest of the part.

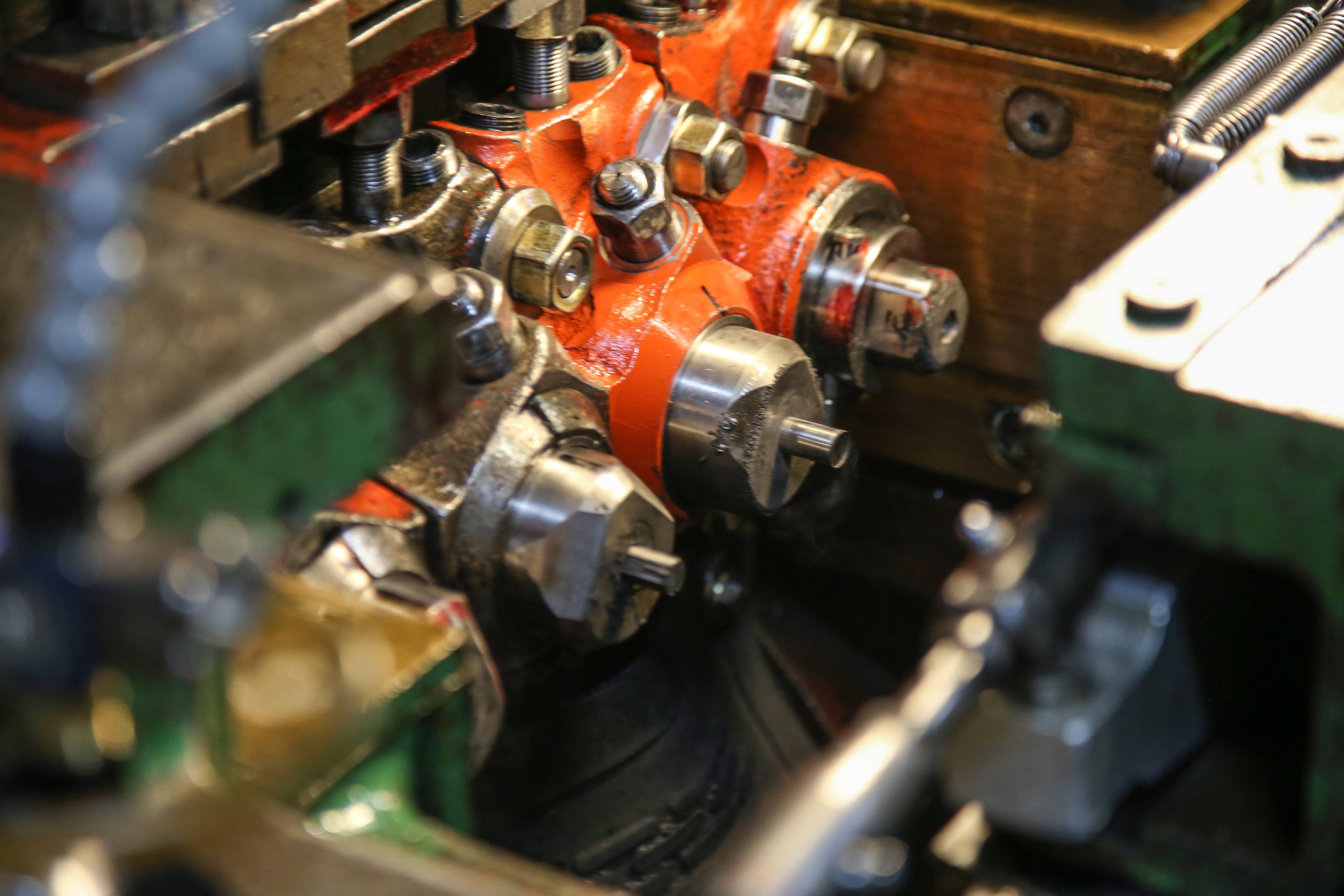

13. Reed thread-rolling machines—originally meant to manufacture spark plugs—have been re-engineered with stronger spindles, bushings, and other parts to roll threads into hardened bolts.

The machine holds three dies and was in the middle of a die swap. Once the bolt is fully formed, it’s off to inspection. Each part gets a quick visual quality check, while every 50th part gets a dimensional inspection on the manufacturing floor. Further inspections happen in a temperature-controlled QC room, where employees use precision instruments to check every dimension.

14. Quality checks are done by hand on every 50th part.

Nuts are run down lightly by hand onto a fixture and a .002 feeler gauge must not slide under the shoulder of the nut on any side. There is a microscopic visual inspection and the threads are also checked with a go, no-go gauge.

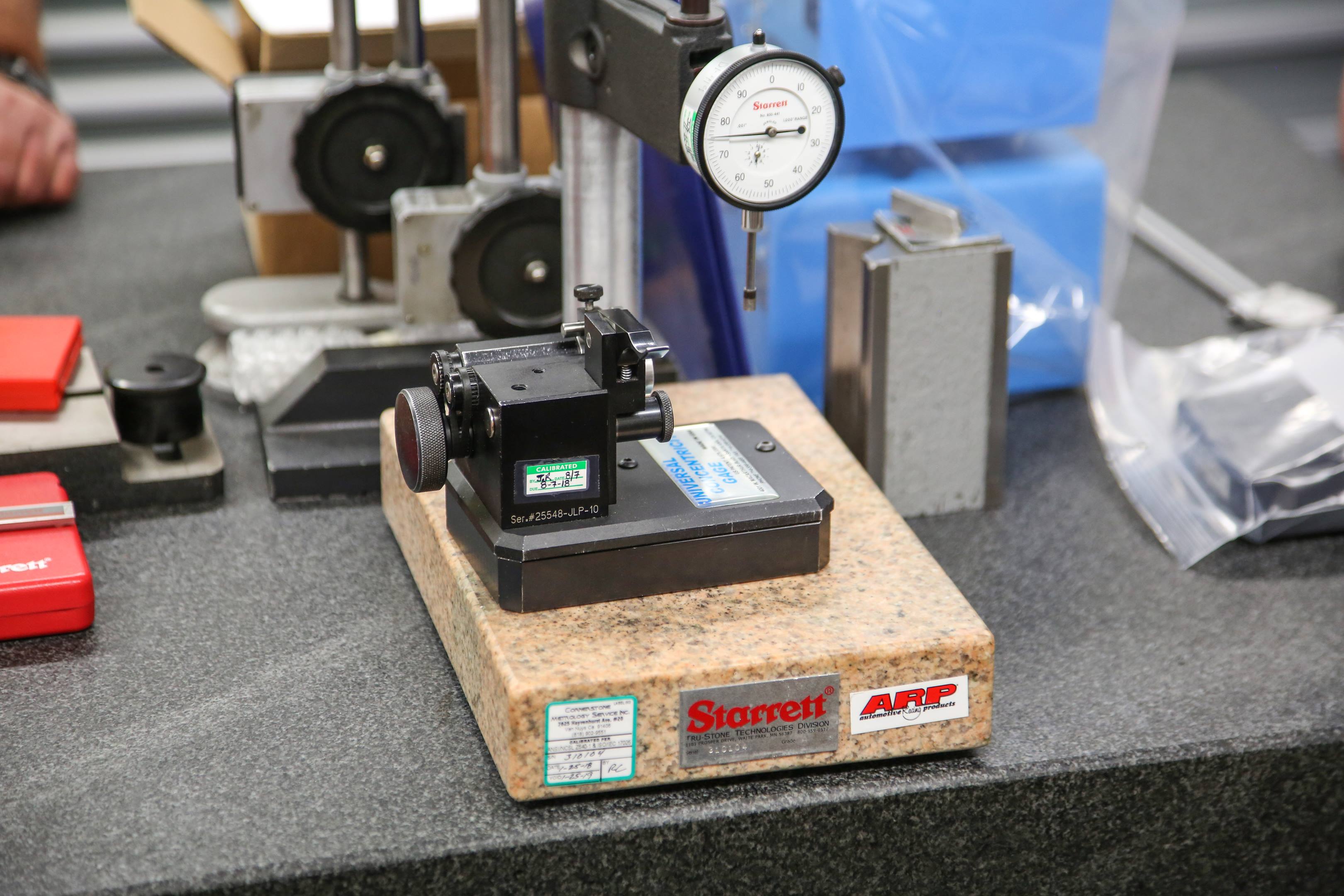

15. The inspection room is filled with all sorts of measurement tools, from state-of-the-art laser scanners to precision dial indicators like this one.

With manufacturing complete, bolts are moved a nearby facility, where they’re placed in buckets and racked on pallets until it’s time for them to be packaged and shipped out to the distributors. To ensure each package contains the right parts, the label printer is linked to a scale. If the parts don’t match the expected weight, the readout turns red and the label won’t print.

16. The final stage of production is packaging, where parts receive their label. This scale ensures that each package has the proper components before the corresponding label is printed.