5 ways to bleed your brakes: Get the air out

Bleeding the brakes is an inevitable part of DIY automotive repairs. Air can enter the brake system during repairs, but the more common reason is far more insidious. Brake fluid is hygroscopic and readily absorbs water from the atmosphere. Water in the brake fluid lowers its boiling point. Heat boils the brake fluid, and the resulting steam leaves air in the lines. Brake fluid is incompressible while air is easily compressed and manifests as a spongy brake pedal or worse.

Meanwhile, contaminated brake fluid attacks rubber, iron, and steel. Black gunk in the reservoir means the war against hoses, caliper piston seals, and wheel cylinder seals is well underway. Repairs caused by rotten brake fluid let in more air, and all of it leads back to bleeding the brakes, a required and universally loathed task that almost always leaves one pondering a better way while lying under the car in a cold toxic soup of brake fluid and rust.

As such, we’ve put together five different ways to get old brake fluid and air out and fresh brake fluid in. No matter the method, the prep is the same: soak the bleed screws in penetrating oil, siphon as much rotten crud out of the reservoir as possible, add fresh brake fluid, start with the bleed screw furthest away from the master cylinder, and work back to the closest one. Along with being poisonous, brake fluid destroys paint, so keep a large bucket or plentiful supply of cool, clean water nearby and immediately flush any spills.

Gravity is good

Gravity is the simplest one-person brake bleeding method. Attach the hose to the bleed screw, open it up, and watch old brake fluid and air flow out of the lines like water through the Aqua Virgo aqueduct on the way to Rome. These inexpensive Bleed-O-Matic type setups work well. The small bottle doesn’t hold a lot of brake fluid, but it does help prevent accidentally running the reservoir dry. The magnet makes it easy to stick the bottle in plain view for a reason. We’re not sure if it’s time dilation or sudden flow changes, but sometimes the bottle seems empty one minute and overflowing the next, so keep an eye on gravity.

Pedal and hold

For whatever reason, gravity doesn’t always take hold and the two-person method can pick up where gravity fails. One person sits in the driver’s seat and pumps the brake pedal while the other cracks open and closes the bleed screws. Pressurize. Hold. Bleed. Repeat. Loud callouts of “pump it up” or “pressure” and “hold it down” can make the garage or driveway sound like a Sunday morning at the Waffle House, but the two-person procedure is a tried and true way to get the brakes bled quickly. Communication breakdowns or attention lapses can slow the job, so sort out the callouts and procedures ahead of time.

Vacuum pulled

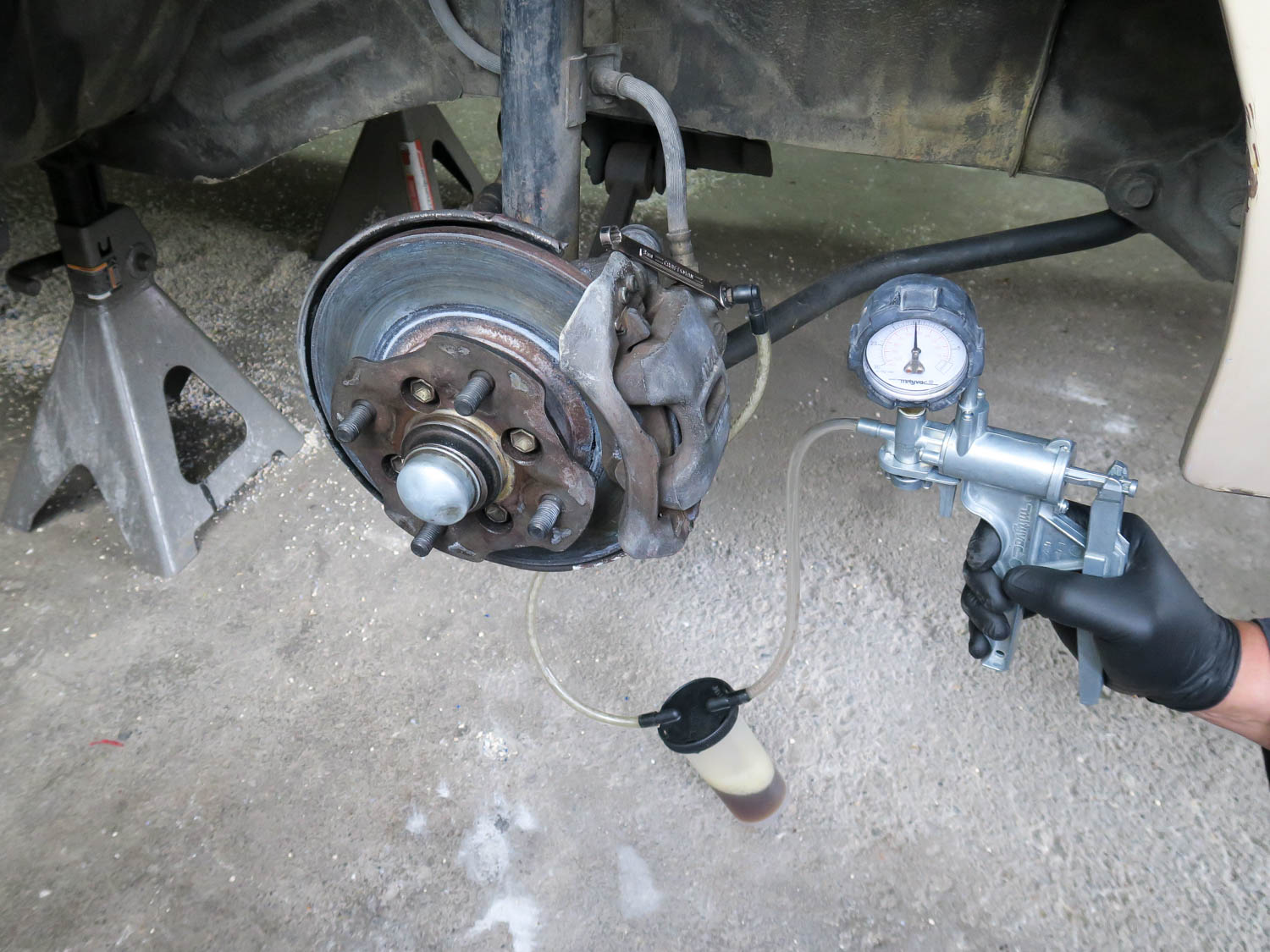

The idea here is to create a vacuum that draws brake fluid and air out of the bleed screws into a catch container. A hand-operated vacuum gun is a decent option, especially if you already have one around. This Mighty-Vac unit came with all the brake bleeding attachments and is rigged with fresh vinyl tubing. First, hook up the bleed screw adapter, hoses, and catch container. Then pull some vacuum and crack the bleed screw. The procedure can be tricky as air sometimes gets in around the bleed screw threads and creates a tube full of bubbles. Slathering some heavy bearing grease around the bleed screw base can help stop deceptive bubbling.

Pressure-operated venturi

Another type of vacuum setup uses compressed air and a venturi to draw brake fluid and air out at the bleed screw. This system can create the same bubbles in the line issue as the hand-operated unit, as the venturi-type bleeder gets the job done about the same way. Brake fluid and air gets drawn out of the bleed screw and flows quickly through the hose even if it doesn’t seem that way, so this unit came with a large catch can and a few supply bottles that sit upside down in the reservoir. On the negative side, the venturi bleeder we used here pulls a lot of air through the compressor and was a bit more finicky than the hand-operated setup.

Pressure tank

Some consider the pressure tank brake bleeder the very best there is. When you absolutely, positively want to push every last molecule of air and rotten brake fluid out of the system, accept no substitutes. The Motive unit shown here is one of many, but the concept is the same. Pressure check the tank-to-master-cylinder connection for leaks with air only, depressurize, fill the tank with brake fluid, pressurize, and take a leisurely walk around the car cracking bleed screws with a wrench and catch can. We’re using the universal round pressure cap, but direct fit adapters are available. In this case, the pressure bleeder sorted out the rear ABS brake modulator under the Starion hood like a champ.

All of these methods work. Hopefully you won’t have to try several options before you find the one that works best for you.

A few things to mention. If your vacuum pull method is getting air from around the bleed screw wrap some Teflon tape around the screw. Don’t wrap around the bottom of it! You can by tapped pressure bleeder reservoir caps on Amazon. Most have a standard air fitting. Turn off your air compressor, bleed it down under 40psi or lower. Then hook up to the cap. Too much pressure will pop the reservoir off the master cylinder (messy and not fun) . Watch the fluid level carefully. Don’t store brake fluid in a large container (such as the pressure tank shown) as the fluid will absorb moisture from the air. Today’s biggest bleeding issue is ABS. It traps air and won’t bleed. You need to activate the system to force that air into the lines. Some cars can do this via OBDII apps. If not then drive it on a wet/slick/gravel road and lock up the tires this engaging the ABS. Do this a lot. Over and over. Then go bleed the brakes.

– The combined brake warning switch/pressure proportioning valve on some cars can be triggered by pressure bleeding, requiring a reset procedure, check the shop manual for specific pressures to avoid.

– The suggestions to use penetrating oil on the bleeders and grease to block air when vacuum bleeding probably should be rethought, as one doesn’t want to risk getting petroleum products into the brake system where they will swell and damage rubber seals and hoses. Okay to use a few drops of brake fluid to loosen threads and silicone grease to block air, brake fluid already is there and thick silicone grease is very unlikely to spread and, in any event, won’t damage rubber.

– This should be updated for hybrid vehicles, for instance there are specific methods for bleeding Prius’s that vary by model and involve activating the ABS pump, get it wrong and they throw a bunch of codes that might require a trip to a mechanic. As far as I know they can be vacuum the usual way (and maybe gravity bled), but I don’t know if this flushes the ABS module.

Vacuum type bleeders cause air leaks around the bleeder screw threads when you are bleeding? So what? The air gets sucked out along with the old brake fluid. Shut the bleed screw right before you stop the vacuum, and start the vacuum right before you open the bleed screw. Every single brainless article that mentions vacuum bleeding talks about the air leaks, as if it matters. It don’t matter!!!

This brake bleeding guide from Hagerty is a lifesaver! The step-by-step instructions make it easy for even a novice to follow. I tried it on my classic car, and the improvement in brake performance was noticeable. Kudos to Hagerty for simplifying a critical maintenance task.