3 Ways Engines Can Make Big Power

At one point in history, thermal efficiency was just a kernel of thought brewing in a would-be engineer’s brain. This led to seeking power in the easiest possible way: Making engines with massive displacement. It made sense then, but times have changed and now there are other ways to make engines that produce usable and reliable power, without requiring 800 pounds of cast iron and pistons the size of coffee cans.

The hardest part of this conversation is that there will always be dyed-in-the-wool people who declare there is “no replacement for displacement.” We’ll get to why that may or may not be true, but first let’s talk about why this sentiment exists: The displacement of an engine is essentially the measurement of how much air volume the engine can pump through itself. The easiest way to calculate this is to plug into a formula the engine’s measurements: Bore squared x .7854 x stroke x number of cylinders = cubic inch displacement. Example: A Chevrolet small-block that measures 4″ bore by 3.48″ stroke by 8 cylinders equals 349.8 cubic inches. Most every manufacturer does a little rounding for the sake of cleanliness.

As compression and combustion of the air/fuel mixture is what makes power, the volume of air determines the power potential. More air in means more fuel, which is what holds the potential energy that is converted to kinetic energy when the fuel is burned under compression. There are other factors in the formula though, including rpm and boost, as pointed out by Engineering Explained on YouTube:

While driving, Jason Fenske does the math to calculate the air volume pumped through a hypothetical naturally aspirated engine. This becomes the baseline, and by doubling the rpm ceiling he is able to downsize the engine by half and have the same potential power. Same goes for boost, as adding one additional atmosphere of pressure—14.7 pounds per square inch—allowed the engine size to shrink without needing massive rpm.

This proves there are, in fact, replacements for displacement, but before you leap to the comments section to drag those knuckles across the keyboard in defensive of stone-age technology, let me just agree with you. You’re right. A big, unstressed, slow-churning engine is likely the most durable and easiest-to-produce option. All of these other methods for making power come with trade-offs that are worth discussing. High-rpm and low-displacement often requires a significant amount of additional precision to make the engine live. Same goes for boosted applications.

Is any option always better than another? If only life were that easy. The reality is that there are better engine formulas for different applications. Otherwise, we would all be driving around 28.5-liter four-cylinders. Sounds fun for a bit, but that’s overkill for the average person’s commute.

***

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

There is a lot to do with this.

Displacement was the winner for a century as Technology was just not great on RPM materials or turbos with no electronics or decent oils.

It takes advanced materials and tech for reliable rpm and turbo power.

I had a 2.0 Ecotec that made 300 hp. It was reliable and it was built for the boost at 23 psi with better pistons crank and oils we did not use 20 years ago out side race engines.

Same for the RPM engines.

It is cheap to displacement. It is reliable for a century. Not always efficient.

Like guns are there are different sizes and power. Nothing right or wrong with any but you need to understand each and use the one best fit for the application.

Today so many companies are using small displacement and Turbo because it is efficient. You can make more mpg, better emissions and the benefit is more power.

In the old days bolting a turbo on a pinto engine or a 3.8 was not reliable. They learned that better materials, tech and oils were needed. Not cheap but it meets regulations. .

Very true that the real reason for small displacement turbo engines is that there is an advantage both to weight, size and packaging, all of which are positives. The goal for any powerplant is a balance of power vs. efficiency vs. packaging vs. cost vs. reliability (warranty claims are not something that manufacturers want)- all of these factors come into play. So IMHO the real question is- what is the purpose of the ICE and what is the price point. We are in many ways in the Golden Age of the ICE in that engineering and advances in electronics mean we can have power levels and performance that would have been previously relegated to a full out race engines in a car that delivers 20+ mpg on the highway and you can drive to the grocery store and do your shopping without a hiccup. Simply amazing- still have my old BBC with 3:73 gears and a 4 speed- but that combo gets between 7-8 mpg at 80 on the highway and overheats when stuck in traffic- but I still love the experience.

It is amazing what modern technology can do. I have a car that can do a sub 2.9 0-60 yet give me 28mpg on the highway at a 70mph cruise (assuming I could behave myself with the accelerator). A huge benefit of smaller motors and (generally) forced induction is a better power-to-weight ratio which in turn reaps massive benefits in handling. No longer is it, “as fast as you want to go in a straight line.” New tech brings us great advancements, sometimes at the cost of “getting it right” for the first go ’round.

Regarding technology, many years ago, visited a small auto museum in Balboa Park. They had a Tucker there, and also a Tucker engine in a “glass case” for viewing. The explanation on the engine, was that the failure of the engine was the oil technology was not advanced enough to keep the oil from frothing and foaming, thus not really lubing the engine, and causing failure. Supposed to be one of the factors for the demise of the Tucker.

There is no replacement for displacement.

Why? you can blueprint and balance any engine and strap a big-ol blower to it, but the starting displacement is always going to determine where the end point is, and how much work and expense that is required to get there

Your comment says it all. The other comments are just hitting all around the target.

Application is everything.

A 300 HP turbo 4 is laughable against a 300HP Duramax – for trucks.

But that 350 HP 3.5 EcoBoost is a much better engine in a F150 than a 357 HP V10.

Small turbo 4s are decent commuters, but man was that GM 4cyl Silverado lousy in the AZ mountains.

Here is a question that comes up in the RV Towing crowd. The Ford eco boost engines make enough torque for towing in almost any situation.

Yet Ford does not put the eco boost in 3/4 and 1 ton trucks. Reliability?

I have a GM 2.7 four cylinder with a turbo. The reason I bought it was torque. That engine was designed from the beginning to be a work engine. I have pulled cars that were on a Uhaul auto transporter when the car weighed about 4500 pounds and the trailer weighs over 2000 pounds. Many times I have set the cruise control and climbed many (not small) hills (I know-I wasn’t in the Rockies) and that truck would never downshift. It just kept plugging along.

The article doesn’t mention better fuel delivery. My ND2 Miata uses Mazda’s Sky Active tech, which includes direct injection, to make more horsepower and with better fuel economy than any previous Miata. Granted, it’s a much more complex system, but so far it’s proved to be pretty robust.

I forgot to mention that the ND2 is naturally aspirated… no forced induction.

Twin turbos, 4 Cam, V-6, works for me. 0-60 in 3.1 sec. NOBLE M-400.

In the old days our thought was…If you ain’t got the cubes, you gotta have the revs

If the single goal is to just go fast and nothing else then sure, go big and then bolt on more power and then select your tool of choice to get the fuel air mixture just right.

Reality, the family car of the 1970’s had a straight 6 or a V8 with 250 to 350 CID that put out at best 200 HP on its best day under perfect conditions. That car got maybe 16 MPG at best on the highway in perfect weather with no traffic at 55 MPH. Today a commuter economy box will sit one less person has a 1.4 to 1.8 liter max 4 banger that puts out about 190 HP all day every day while getting 35 MPG all around, and over 40 MPG on the highway at 65+ MPH. On brand new as supplied from the factory tires an average family car from today would eat an average family car from the 1970’s down the quarter and around a track. Safety and fuel economy rules got us here, not bigger engines.

Proof that the replacement for displacement is to turn fuel into forward motion, not heat.

In my 60 plus years of car nut stuff,

The engines that I remember and left an impression are: 327 – 350 hp, 427 “ side oilers” , 426 hemis, Repco Brabham V8, many Ferrari’s and other Italians, and several of the more recent small displacement engines.

The best was my 2JZ .. straight 6 twin cam converted to a single turbo.

At the end, it was dynoed at 768 hp and 726 lbft at 4600 rpm at 28 lbs of boost – max 8000 rpm. In the ‘94 Supra it was awesome.

Gary, what was the displacement of the engine that was dynoed at 768 HP?

The Toyota 2jz engine was a 3 liter straight 6 cyl. when leaving the factory.

My 64 Olds F85 2 dr post car at about 3100 lbs and is equipped with a 73 Olds 455 (8.5 to 1 CR), gets 17 – 18 mpg on the freeway. The build is a Reed Sod Buster cam, GA heads, Edelbrock Torquer intake, 442 exhaust manifolds, 850 cfm Q-jet and Scorpion roller rockers. The trans is a GM Newprocess 4 speed (4th gear is .71 OD) and a 3.08 rear gear yields 1700 rpm at 65 mph. The 1/4 mile is 14.2 seconds @ 98 mph.

They left out the most thermally efficient of all. ELECTRIC. They all have electric starters and batteries. Make the starter and battery a lot bigger and just forget all the rest of the commotion.

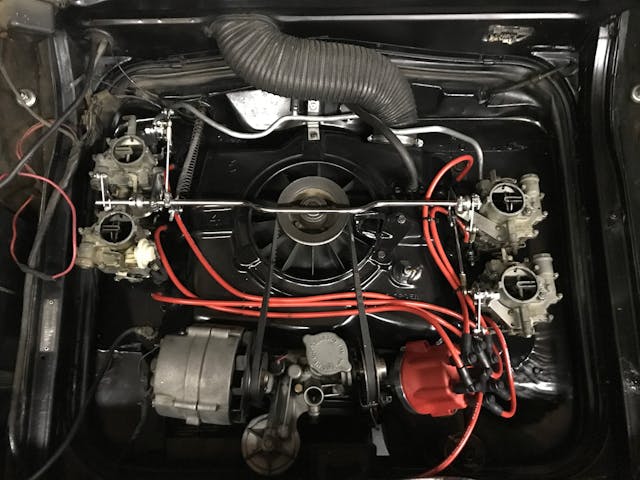

So a Twin Turbo LS swap in the Corvairs future? Just kidding!

Kyle,

This may not be the appropriate forum (I don’t know how else to reach you), but if you’re interested in giving your Corvair a “boost,” I have a 180 HP turbocharged Corvair engine located in central Kansas that I would be willing to part with. Please let me know if you are interested.

I have both. Keep the 140.

I love my 140 for driving on the street but have always been curious to build and run a turbo engine. Might not be ideal for the street, but would be fun to learn about first hand.

Hey Greg, thanks for reaching out. I’d at least be curious in hearing more. Can you email me at klsmith@hagerty.com and we can talk more? I’m headed for central Kansas in early May for the McPherson College CARS Show and could possibly make time for a detour.

Way back, I had a 1962 Corvair Monza Spyder ragtop with factory 150 HP turbo connected to a single side-draft Carter carb, chrome cross pipes to each side. It worked well, especially with the studded snows.

The main problem with smaller displacement engines is lack of torque. If you want to be fast with a smaller displacement engine ,you have to up the efficiency and horse power and lower the weight. I used to run a 1964 Nova with a 327 pumping out about 400 Hp and I routinely beat out the big blocks in roadable trim. The key was I was lighter I did not need all that torque that often broke things. I also got a lot of the power to the ground by tuning the suspension.

Robert, Small displacement turbo motors can be built to produce torque as easily as high RPM horsepower. The 2L turbo in my wife’s car makes 330 HP & 350 lb/ft, with 100% of that torque available at 1800 RPM; just slightly less than the 5.3 Chevy puts in the Silverado (355 HP & 383 lb/ft).

Anybody into nitrous?

Yes C Duster I’m an experienced nitrous oxide user. Docile street economy punctuated by phenomenal power boost at the press of a button. Comically simple installation, easily reversible.

I am sure its far more complex than the what is mentioned in this short article. OK, displacement and internal pressure, whether this is achieved by compression ratio or external means (Turbo charging or supercharging).

Bore to stroke ratio comes into the equation, which I suppose leads to the higher RPM scenario and therefore higher power. However, gas flow must be considered and therefore the efficient routing of fuel in and exhaust out becomes important.

Next – fuel. These days as we seek alternatives to straight petrol (OK – gas for those the other side of the pond) the use of ethanol is a reality. However, consider what fuels racers used pre war. Methanol, Alcohol and other hydrocarbons were all tried. Some mixtures gave much higher powers than straight gas. Also Nitrous, hit the NOX button and you get a serious boost in power.

So, in conclusion this is a far more complex subject than just engine size.

I can definitely tell you, we do LOTS more heavy engine repair and replacement at the dealership I work at now with the forced induction, direct injection engines now than the larger displacement engines of 20 years ago. Are they better? I’ll let you decide. But I know which engines I’ve seen with 300k plus on them. And I know how many I’ve seen blow with less than 100k…