What’s the most loved/hated carburetor induction system?

While I have concerns that I may draw your ire by sucking you into another question for our According to You series, such is my job. I rarely choke when it comes time to go full throttle for the Hagerty Community, so let me ask this question and offer some suggestions to spur discussion in the comments:

What’s the most loved (or hated?) carburetor induction system?

I hope the slideshow above provides some inspiration. But if you need to hear a new set of suggestions, ones that are rarely given the oxygen of publicity?

Get jetted up for these two or perhaps adjust your idle speed, because these embody the love and hate that only a lover of Lincoln and Mercury vehicles could embrace.

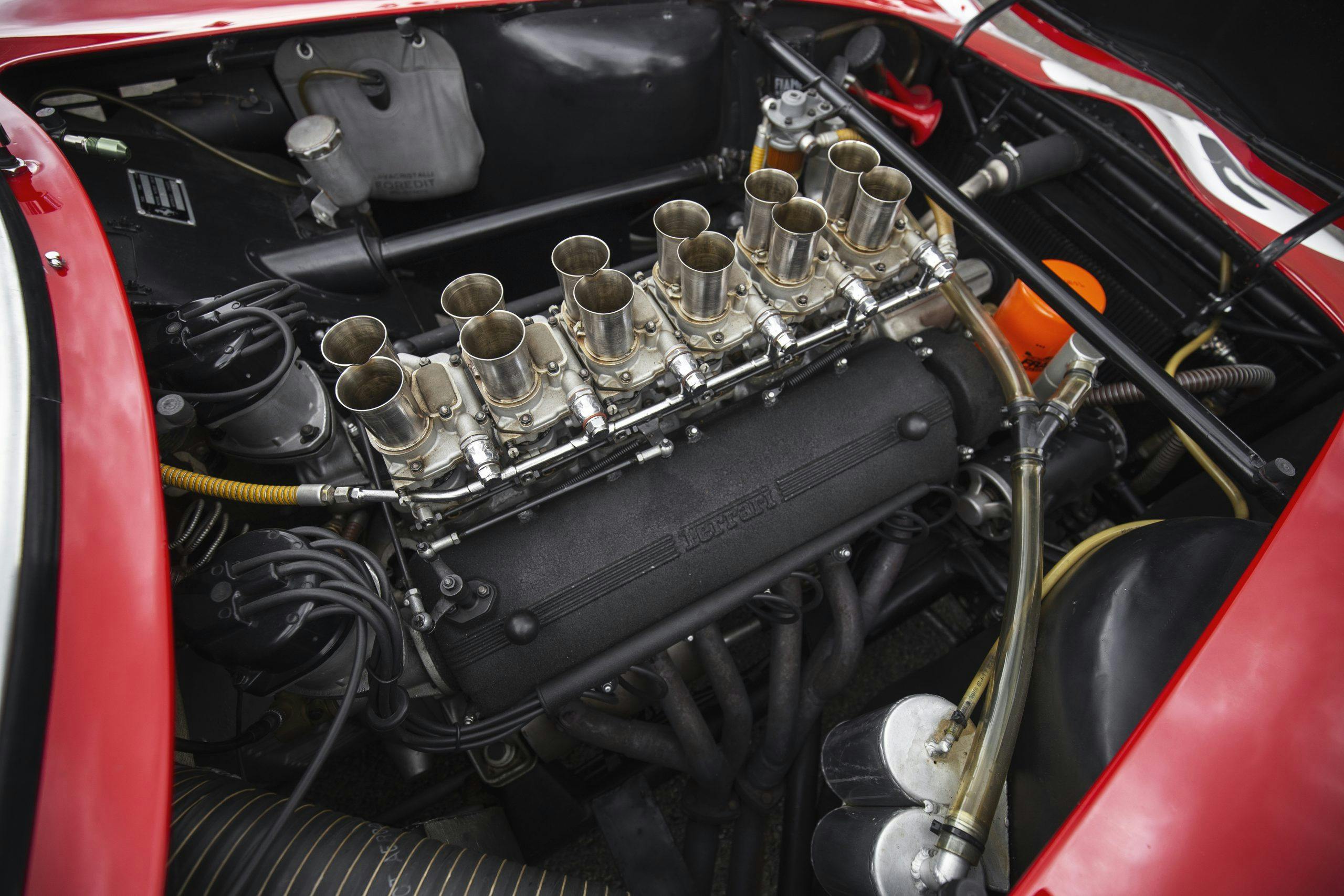

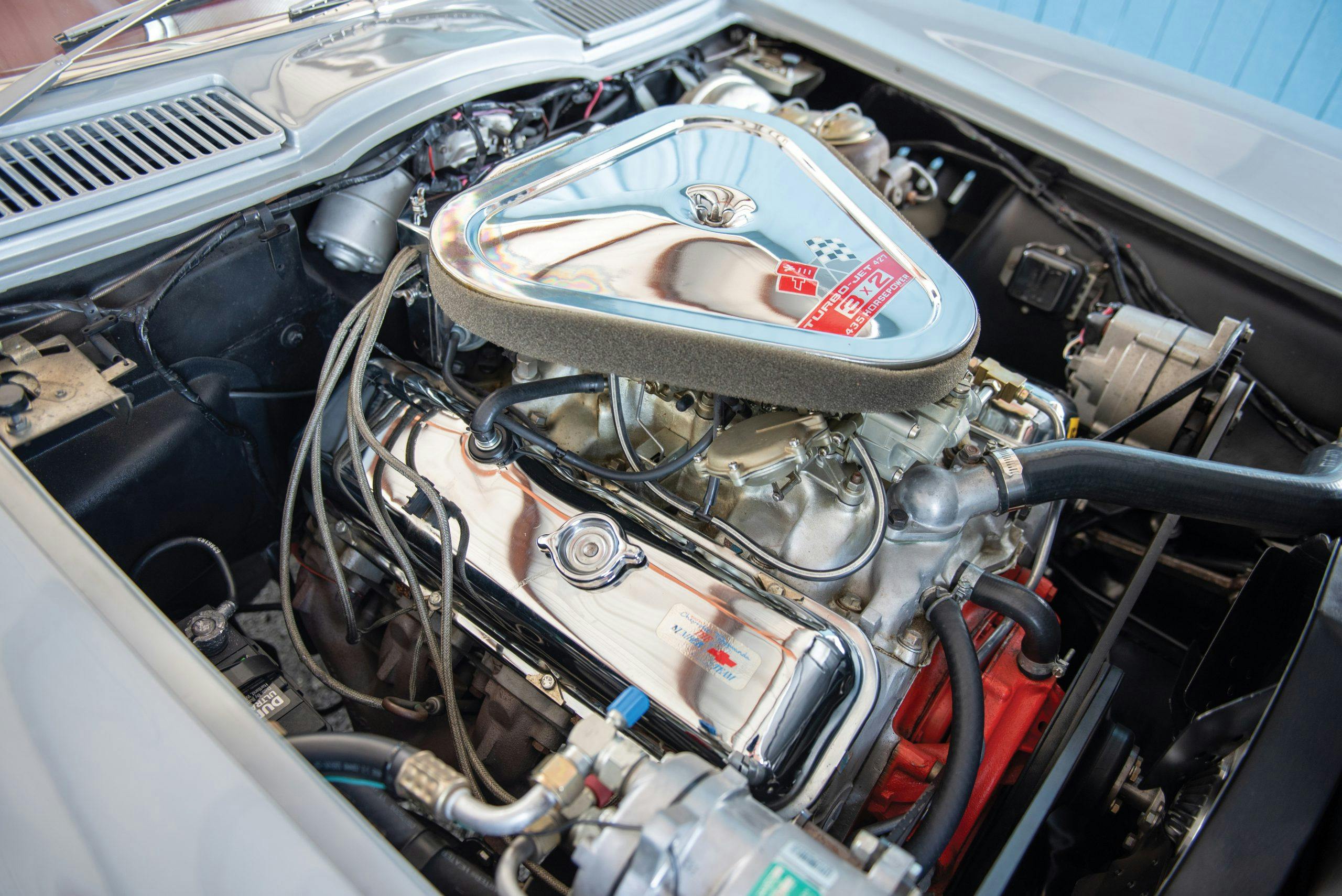

The one I love: Super Marauder

How can you not love the first engine to make 400 horsepower? On the 1958 Super Marauder engine, the triple carburetor setup was hidden under a finned aluminum cover, boldly proclaiming the mill’s advertised output in the process. Beyond cool. 430 cubic inches making that much horsepower likely broke a few hearts at your local stop-light grand prix in the late 1950s. What a shame this particular configuration was only available for one year!

But I am here to break the Super Marauder’s heart once again, as this Lincoln-Mercury fanboi grew up in a different era and saw other forms of induction as a budding automotive enthusiast.

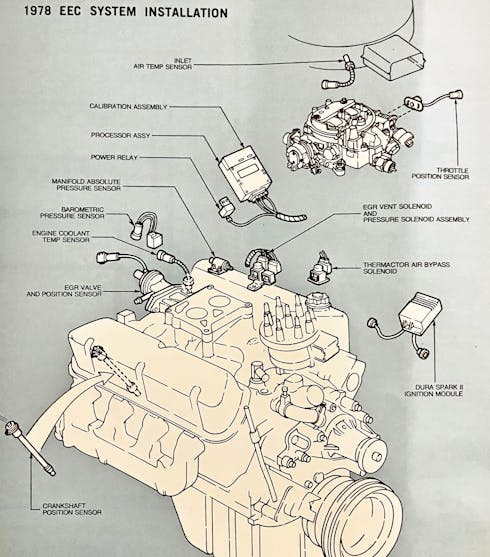

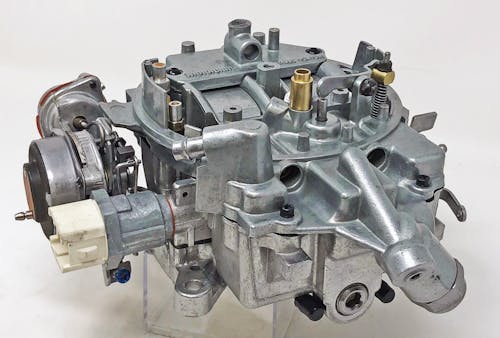

My secret crush: EEC I + Variable Venturi Carburation

Sometimes it is not easy being Gen X; I grew up with slow cars that got faster as the Malaise Era turned into the modern era. There were a few systems that started that path to 717-hp Hellcats, 650-hp Camaro ZL1s, and 700-hp F-150 Raptor R trucks. Chrysler had Lean Burn, General Motors had E4M Quadrajets with Computer Command Control (CCC), and Ford had Variable Venturi carburetors with Electronic Engine Control (EEC).

No matter the automaker, these systems all lived short yet inspirational lives for future vehicles with fuel injection. But only Ford kept the naming convention: through the first EEC-I carburetor in the mid-1970s to today’s EEC-VII for modern vehicle needs and concerns. I love and hate the history of EEC: I love to enjoy it from a historical perspective, but hate to fix it when the technology fails over time and/or usage.

Then again, that notion got spun on its head when I learned that the failed idle circuit on my fuel-injected, EEC-III-powered, 1983 Lincoln Continental was easily, quickly, and affordably addressed with parts from EEC-I and its Variable Venturi–carbureted forefathers.

I mean, you coulda knocked me over with a feather. One new vacuum diaphragm (I got two because they were $5 each!) in the EEC-III induction system and the Continental ran like new again! Like new, but not like a new car, of course: The EEC-III setup is slow, clumsy, and nothing more than a fun throwback to the bad old days of my childhood.

But I’ve gone way off-topic, possibly with little benefit to the Hagerty Community. So again, I implore you: What’s the most loved (or hated?) carburetor induction system?

***

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

in 1966 i was working at an Olds dealer doing new car service. The factory didn’t finish the cars then, we had to check the cars over and install the carpets. The Toro had the Qjet and it soon developed issues. Cars came in with rough idle and dying issues. they were flooding due to a little diaphragm that was used instead the needle and seat to maintain fuel level. it would tear causing flooding. Soon replaced with needle and seat to correct design. My favorite issue (not all of the Toro’s) the large swedged in metal plug on the carb front could fall out. When starting or attempted restarting, the fuel flowing toward the rear of the engine would be ignited as the vapors flowed past the distributer. The now flaming gas ran down the rear of the block across the starter. The melted insulation shorted out and started the engine cranking, thereby insuring a continuous fuel supply for the fire. All of the cars I saw were totaled from either fire or smoke damage.