Homegrown: The GDT Speedster is the ultimate retirement special

Welcome to Homegrown—a new limited series about homebuilt cars and the ingenuity of their visionary creators. Know a car and builder that might fit the bill? Send us an email at tips@hagerty.com with the subject line HOMEGROWN. Read about more Homegrown creations here. —Ed.

Retirement usually means moving to some southern clime and ceremoniously pitching the alarm clock out the window. Gene Dickirson, 80, who resides in Plymouth, Michigan, only a few miles north of Hagerty’s editorial offices, turned a cold shoulder to those traditions in order to indulge his childhood fantasy—constructing a sports car from scratch.

This ambitious endeavor began in 2000 following Dickirson’s 36-year engineering career at Ford. And instead of consuming decades, his effort produced a running car in less than six years. That’s because step one was to create a miniature Ford Motor Company—minus the bureaucracy—comprised of five retirees, four colleagues still holding down day jobs, and one patient, understanding wife. “Barbara’s most notable contribution,” Dickirson notes, “was the project’s name: Gene Dickirson Team Speedster.

“Before the hands-on work started, we debated ideas during lunch-hour and evening meetings, voting on hundreds of details to achieve a consensus as to what the final design should be. My three-car garage served nicely as our base of operations. We agreed from the beginning that when our creation was finally sold, every participant would share in any profit realized.

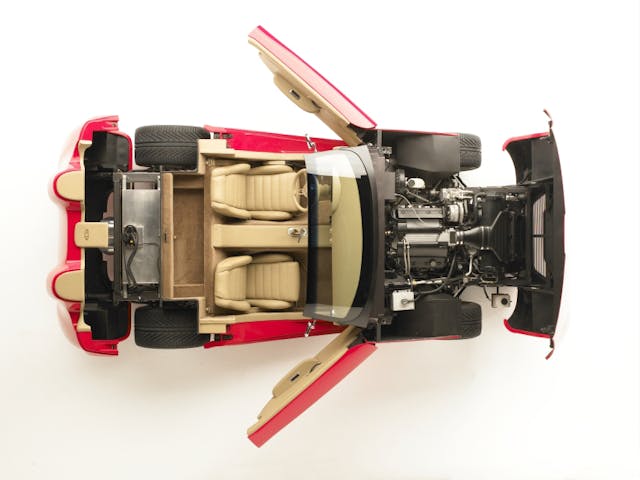

“We selected a two-seat roadster body style to achieve an enjoyable summertime ride while avoiding the complexity of top construction. Following standard industry practice, we wrote down key product features and defined our hard points. Ford designers Larry Ronzi and Craig Sandvig sculpted our 1/8-scale clay model. Visteon engineer Keith Rogalski used non-contact scanning to digitize the dimensions before Larry Conger converted those figures to full scale using ICEM Surf industrial design software. A full-size body we made out of foam also came in quite handy.

“Dave Maran fabricated wood models and constructed our welding fixtures. Throughout this endeavor, Chuck Carlson ably served as assistant chief engineer. Once we had finalized door, hood, and deck cutlines, we transmitted our CAD data to Method Industries in Palmetto, Florida, where first molds and then body panels were made using fiberglass and Kevlar doused with vinyl-ester resin.

“Upon receipt of the exterior panels, we designed and developed door, hood, and deck hinges and latching hardware. Other projects included designing the dash, steering wheel, door trim, and an aluminum grille. Visteon engineer James Wilber guided the wiring, A/C register design, and instrumentation effort. Musa Azzouz made sure the occupant-restraint anchors had sufficient strength. Cerullo Performance in California stitched leather upholstery onto our sport seats. The leather-wrapped Lecarra steering wheel came from Lokar.

“A totaled 1994 Corvette served nicely as our organ donor. This $5682 wreck rolled into my garage in running condition but stripped of most of its body and interior parts. The 300-horse Chevy V-8 and Hydramatic 4L60E four-speed automatic ran well, requiring little more than a thorough cleaning before returning to the road.

“Instead of using the Corvette’s twisted frame, we designed and constructed our own perimeter chassis out of 1/8-inch-wall rectangular tubing. Although we farmed out the steel cutting and welding to nearby fab shops, a dozen visits were required to supervise that work. We paid a local Chevy dealer to check the final dimensions to ensure they met factory tolerances.

“Our 96.2-inch wheelbase is shared with the Corvette, along with key body-to-chassis mounting points and suspension hardware. While our Speedster is more than a foot shorter than the Corvette, it’s 3.6 inches wider. Curb weight is more than a hundred pounds lighter. By angling the windshield only 19 degrees up from horizontal, our stance is more than four inches lower than the Corvette’s. Our cut-down 2001 Jeep Cherokee windshield is supported by one-inch steel tubing running about halfway up its sides, while the upper periphery is finished with epoxy resin.

“We made our own 16-gallon fuel tank out of welded sheet aluminum. It sits just behind a luggage compartment accessible by lifting the hinged tail section. Our 18-inch Fikse aluminum wheels wear Michelin Pilot Sport performance radials.”

The team’s final tally listed approximately 2000 components, some 13,000 hours of effort, and $66,364 spent on parts and outside services. The first drive around the block occurred in 2005. “That was a thrill I’ll never forget,” Dickirson recalls. “Our car ran straight and true at highway speeds and felt as agile as any Corvette on winding roads.” Using the donor car’s VIN expedited the licensing process.

While beauty is in the eye of the beholder, the GDT Speedster has earned its share of appreciation. Car and Driver blessed this effort with an Editor’s Choice trophy at the 2006 Rolling Sculpture gathering held in Ann Arbor.

Less than 1000 miles were logged before the GDT Speedster was dispatched to auction, the game plan from the beginning. Hopes were high that a buyer willing to spend $200,000 might be found. While that fantasy wasn’t realized, the late Texas attorney John O’Quinn did add the GDT Speedster to his enormous collection in early 2007 for a gavel price of $60,000.

Dickirson believes the GDT Speedster is now in the hands of an Arkoma, Oklahoma, owner. Without further ado, he and his team promptly began designing another homebuilt two-seater, this time a coupe. Watch this space to see how that effort turns out.

***

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

As soon as I saw the top down look I saw the Corvette here.

I am shocked more don’t rebody C5 Vettes as the body panels are just bolted on like a Fiero. They offer wide body kits to make it look like the race car.

I am just shocked they did not lose much weight. The panels must be heavy.

I like the car over all but it needs more detail to the nose and rear as it just has no real feel or personality.

The headlamps and grill make it look a little like a odd weird smile.

I think with a little more time styling the nose it would have helped the car garner a larger price. It really is a nice car with a good personality.

I always envisioned my C5 with no rear trunk and a speedster windshield. This gives some idea of that.

I’m with ya, definitely still a fine effort. I imagine it’s a blast to drive!

It sort of looks like, “Lightning McQueen” from the Disney movie series “Cars”. Same front face and the same smooth curves. It’s even the same palette of red. If this was their objective, they could have greatly reduced development time by simply scaling up a die-cast toy version of “Lightning McQueen”.

It’s interesting but I’d rather have a C4 ZR-1 myself.

The financials sound about right: spend $X (not including labour) on a build and sell it for $X minus 10%… Been there, done that. Still great fun!

That straight on front shot looks like a truly smiling car, with the headrests through the windscreen providing a true “eyes” effect. I like it!

The gas tank location???

“Barbara’s most notable contribution,” Dickirson notes, “was the project’s name: Gene Dickirson Team Speedster.”

Oh I think her most notable contribution was not serving the divorce papers…

Excellent effort, styling is always the hardest thing to get right. Kudos for getting it to the auction block