Homegrown: Scaled-down Cobra has both bark and bite

Welcome to Homegrown—a new limited series about homebuilt cars and the ingenuity of their visionary creators. Know a car and builder that might fit the bill? Send us an email at tips@hagerty.com with the subject line HOMEGROWN. Read about more Homegrown creations here. —Ed.

Like every car enthusiast, Troy Jensen, of Caldwell, Idaho, harbors fantasies of a Shelby Cobra coiled in his parking spot. What distinguishes this 54-year-old mechanical engineer from most dreamers, however, is that he successfully converted 14 years of spare time into the running, driving homegrown snake you see here. (Use your imagination to see what this sports car will look like once its fiberglass skin is finally finished.)

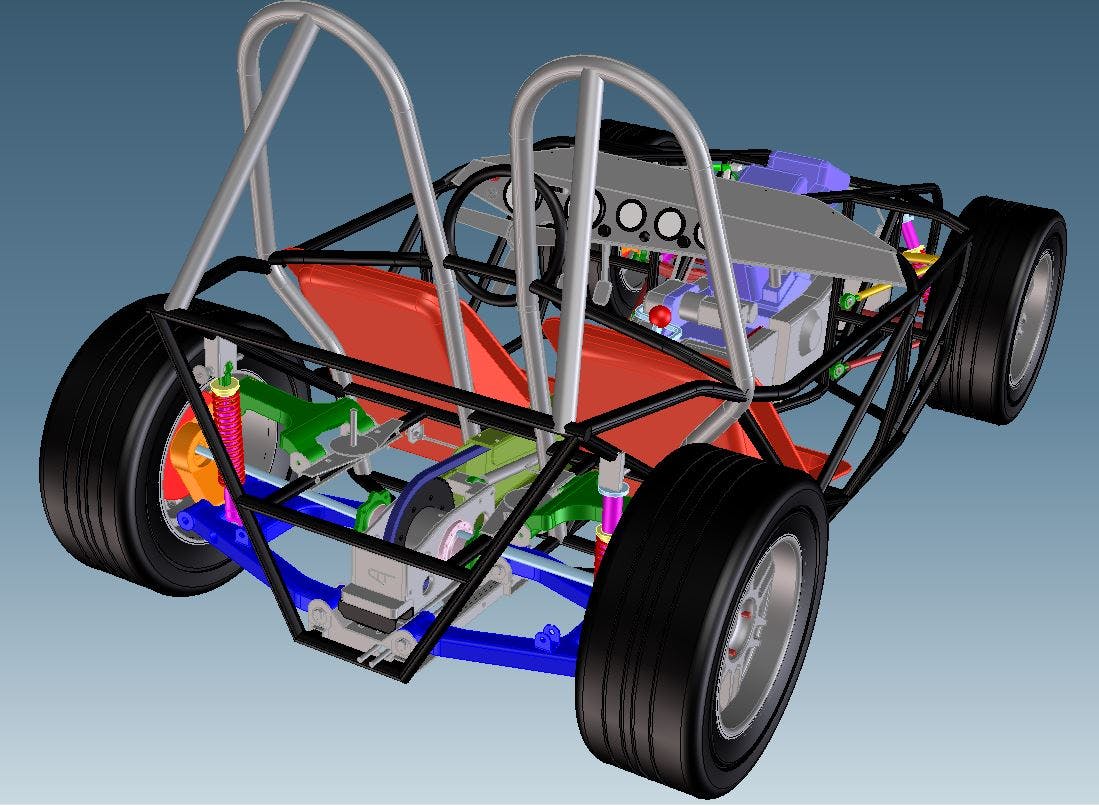

“From the start,” Jensen explained, “it was clear that purchasing an actual Cobra or even a Factory Five kit was beyond my means. The exhilarating growl of a big-block Ford V-8 was also out of reach. The good news is that my CAD [computer-aided design] skills allowed me to follow cost-conscious alternative paths to my goal line.

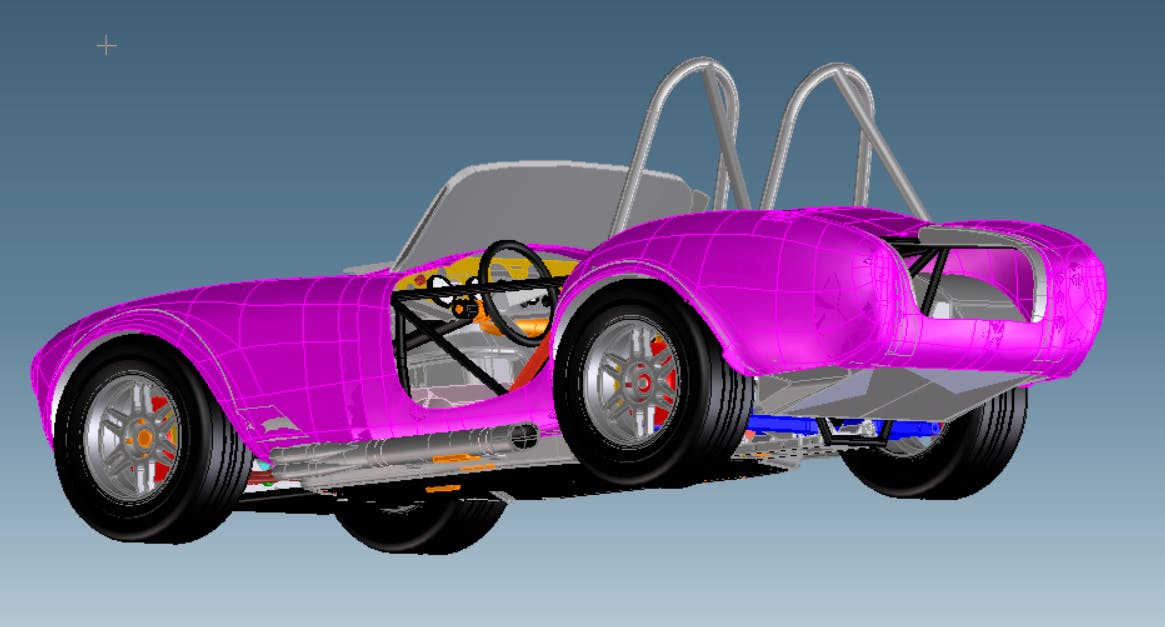

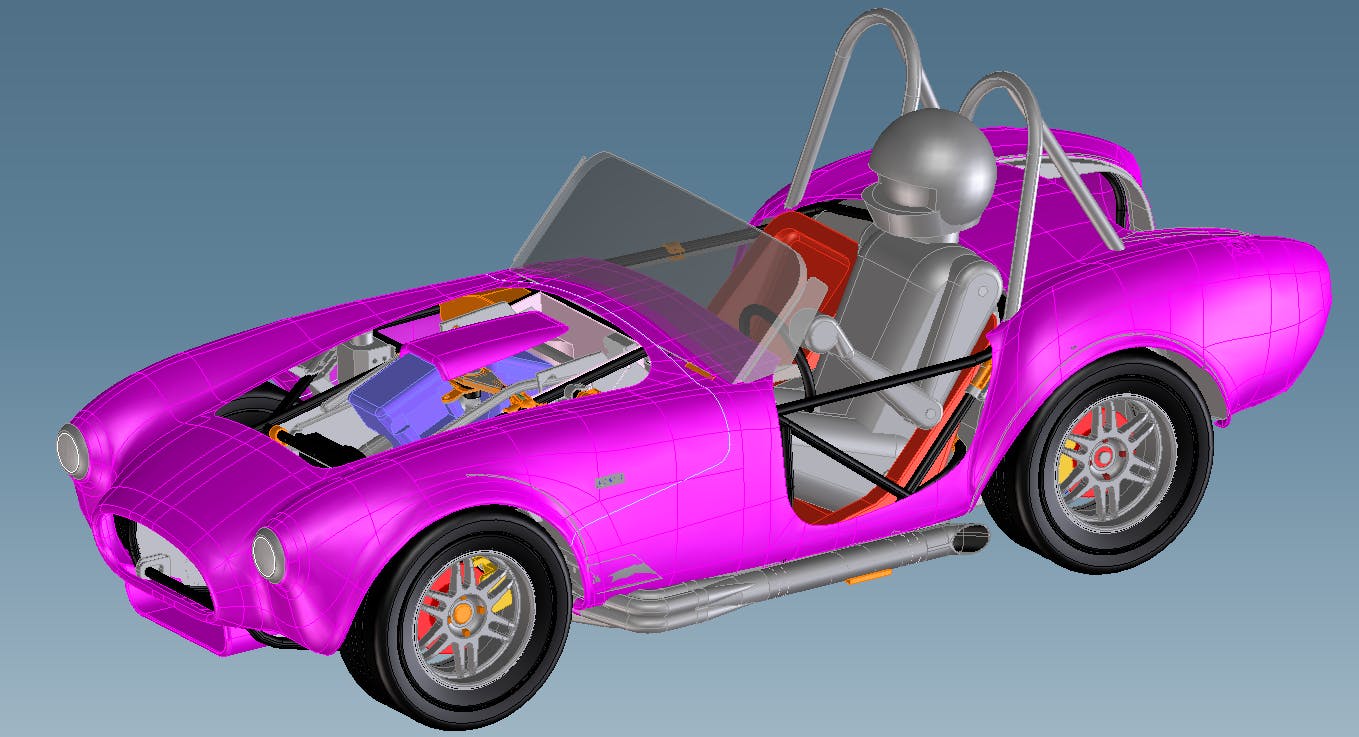

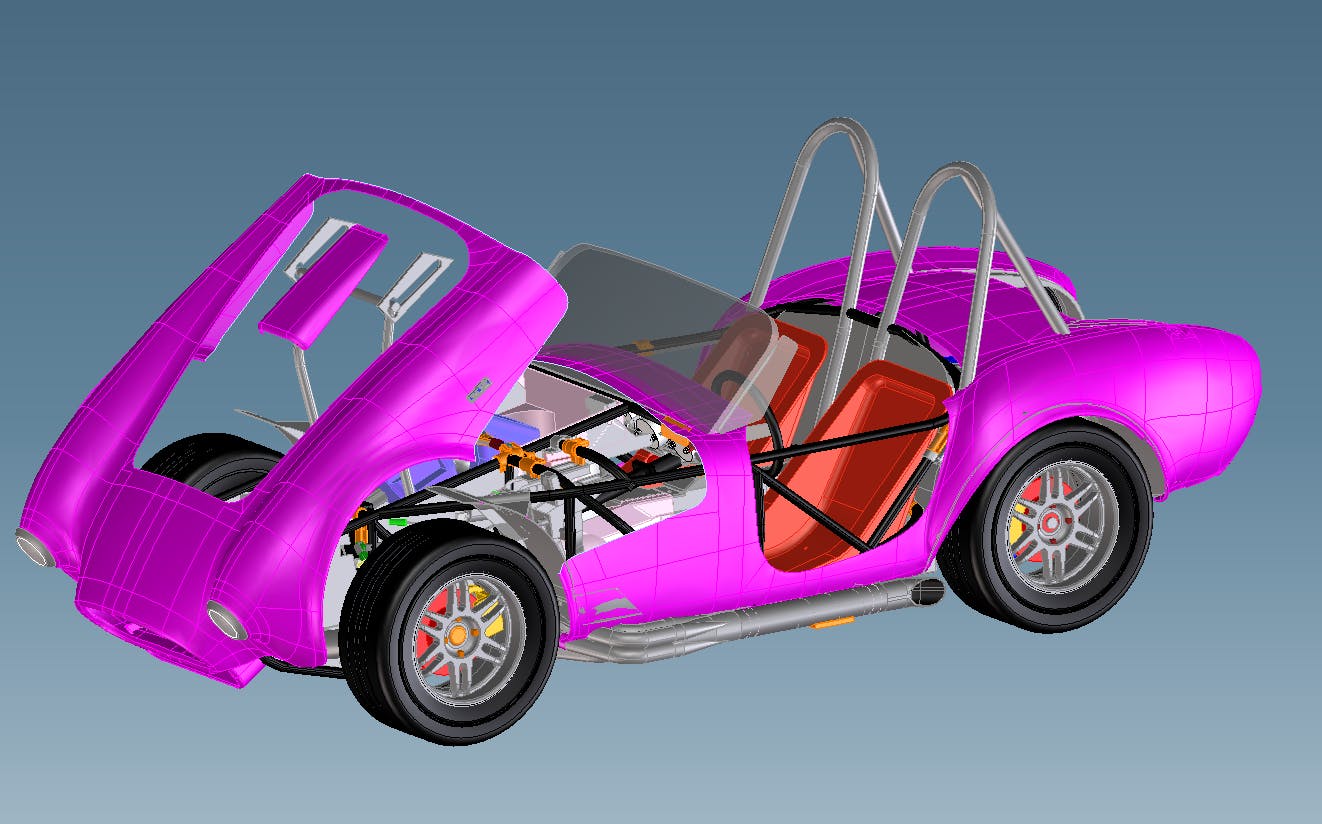

“To approach the performance of the third-generation Mazda RX-7 I’ve owned for years, I decided that simply scaling down a real Cobra made the most sense. When a 3/4th-scale design failed to accommodate my 5-foot, 11-inch build, I upped the ante to 8/10th-scale. That approach yielded a tidy 72-inch wheelbase, a length barely over 10 feet, and a 55-inch maximum width. At this juncture, my car is successful in autocross events without a hint of bodywork. Given the fact this is a lifetime project that may never reach what naysayers consider ‘finished’ status, I’m happy to enjoy my pet’s current acceleration, braking, and agility prowess.

“When a friend challenged the ‘go-kart’ descriptor I used to explain this car, I coined the more evocative ‘Rattlesnake’ name. I’m happy to add that friends and family members have supported this fantasy from its start.”

We asked Jensen to describe how he downsized a Ford V-8 to suit his 8/10th-scale predator. He responded: “The syncopated thump of a Harley-Davidson V-twin has always been music in my ears. Then, out of the blue, my close friend Jason’s Buell Cyclone, powered by an air-cooled 91-horsepower, 1203cc V-twin, was wiped out by an errant Saturn. Fortunately, he walked away from the accident with minimal injuries; after the dust settled, he bestowed his bike engine to my cause.”

That begged the question: Is this Rattlesnake a four-wheeled motorcycle? “That’s actually not a bad way to describe it,” Jensen said. “I built the spaceframe out of light, stiff 4130 chromoly tubing. Nearly all the steering, suspension, brake, and half-shaft parts are from a first-generation [NA] Mazda Miata. There’s an unholy mix of other components from Legends-series dirt-track race cars and from snowmobiles, as well as several 3D-printed parts. You wouldn’t be wrong calling my Rattlesnake a junkyard dog.

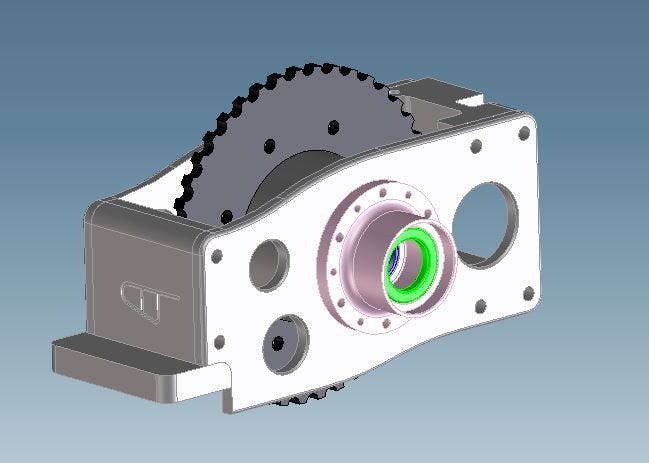

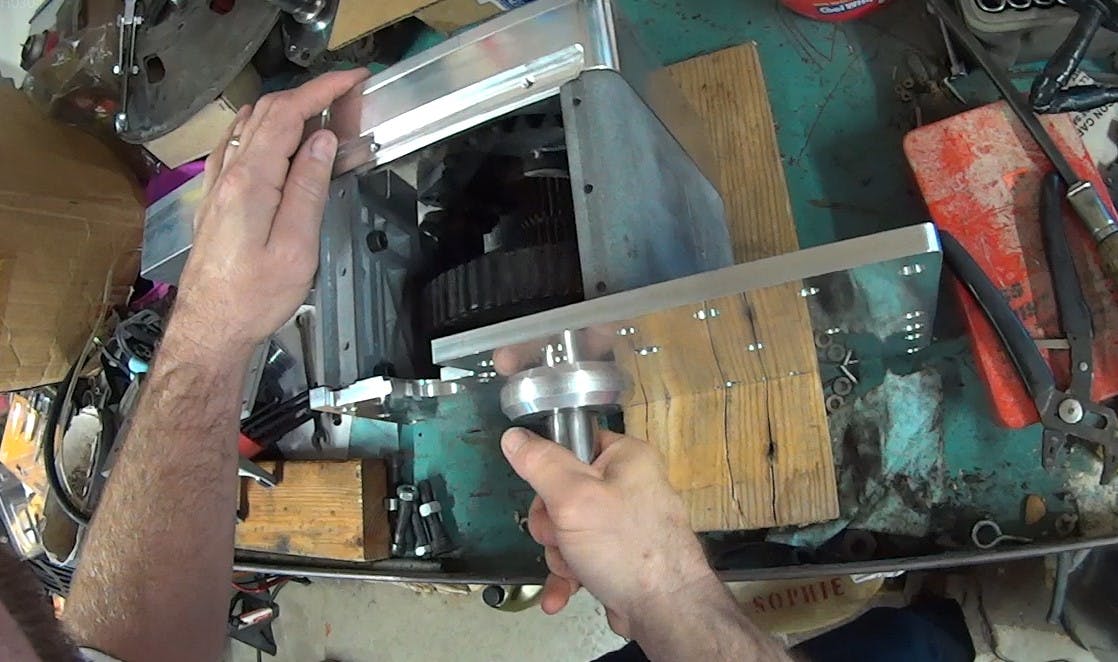

“One major challenge was adapting the Buell’s integral five-speed, no-reverse transmission. To accommodate my two-seat cockpit, I ran the Buell’s right-side power output back to the car’s centerline via chain into a transfer case providing a reverse gear. A second chain runs from that box to a Miata differential reconfigured for chain drive. Miata half shafts are shortened to provide a 44-inch rear track dimension versus 43 inches up front.

“Shopping for Cobra-esque wheels at Tire Rack, the ones I preferred were of course the most expensive. They’re 7-inch-wide, 12-spoke Enkei RPF1s fitted with Toyo R888R racing radials sized 185/60R14 in front and 225/50R14 at the rear. I found a nice tight pair of bucket seats in the Speedway Motors catalog. A friend donated a Bugeye Sprite’s windshield that I hope to use after it’s been narrowed to fit my cowl.”

One Rattlesnake oddity is what appears to be no fewer than four header pipes collected into one large exhaust pipe running down each side of the car. “I was going for the true Cobra flavor here, even though each side pipe is fed by only one cylinder,” Jensen said. “The other three pipes merging into each collector are capped off. It turns out that this arrangement causes internal reverberation, magnifying the rumble, especially at idle.”

Jensen plans to continue his scaled-down Cobra theme in the bodywork. “I have begun making the smaller inner panels out of 3D-printed parts,” he said. “The outer shell will consist of four molded-fiberglass pieces: a hinged nose section with a forward opening for engine-cooling air, a panel running down each side, and a fixed trunk compartment cover. To avoid the complexity and weight of hinged doors, the driver and passenger will simply step aboard over the side panels. While my current fuel tank holds only two gallons, I intend to install a larger capacity tank in the trunk upon completion of the fiberglass panels.”

Like other home builders, Jensen has avoided keeping detailed estimates of the time and money he’s invested. “I’d guess my parts outlay is around $7000 thus far,” he revealed. “For every hour spent actually cutting, welding, and fabricating, I probably spent 10 hours on the computer designing that aspect of the car. Hands-on construction consumed roughly 2000 hours spread over 14 years. And while I haven’t yet rolled Rattlesnake across any scales, I’d estimate it weighs only 800 pounds, without a driver, which is why its maneuverability is so exhilarating.”

Adding plates to legalize Rattlesnake for road use is another thought-provoking concern. “Thus far I’ve fine-tuned my car during quick jaunts around the neighborhood, using a trailer to attend autocross events,” he said. “I have fond hopes of visiting a road course, drag strip, and possibly the Bonneville Salt Flats to document performance.

“While there are off-road and utility-vehicle categories available for obtaining Idaho license plates once I’ve passed a safety inspection, long trips on major highways are not part of my game plan. The reason is because of the ugly squishing sounds that would result from any confrontation between my ultralight roadster and some hulking semi-tractor trailer rig.”

***

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

Way to go, Troy – fellow Idaho boy! I’m digging the Rattlesnake build so far, and hope I get to see it completed.

Very cool project! As a long-time Buell rider, I’m a big fan of his propulsion choice. 🙂 Best wishes and I hope to see progress updates.

Those detailed plans could be a big seller ! Maybe a turbo Mazda rotary engine would fit in there. Awsome article !

I love it! What would I love more? Some way to see more detail on the build and follow the progress. Is there a build page we could find and follow? I would also really love to hear that thumper in action!

Looks very cool. Its a go-kart I bet in handling.

With accurate computer-generated drawings, the possibility of a plan set for another builder shouldn’t be overlooked.

I’m sure that it would be a saleable set of plans as there are many who just can’t spring for a Factory-5 or other full kit, but just might be able to swing a home built of this type.

And a lot of people could do the 3-D printed panels given the program, again, it should be possible to sell these.

I’ll say the same thing i would have said when i was 18 in ’69. This is so cool!!!

Hopefully the Buell donor was powered by 140+ hp Rotax not 60+ HD engine!

Have been a fan of bike-engined specials for the last 30 years….you don’t need an LS to shove 800 lbs around at a decent clip.

Nice write up, has been fun to see your progress over the years… and my sons still talk about the time to took them for ride in it!