Back From The Depths

It was swallowed whole in a bizarre accident. Then GM’s “signature restoration” on the one-millionth Corvette brought it back to life.

The ground rumbled and then opened beneath the floor of the Skydome at the National Corvette Museum in Bowling Green, Kentucky, in the early morning hours of February 12, 2014. In this surreal scene captured on video, eight significant Corvettes tumbled 40 to 60 feet down into the rocky bottom of a sinkhole. It is the most bizarre incident ever to occur in the collector car world.

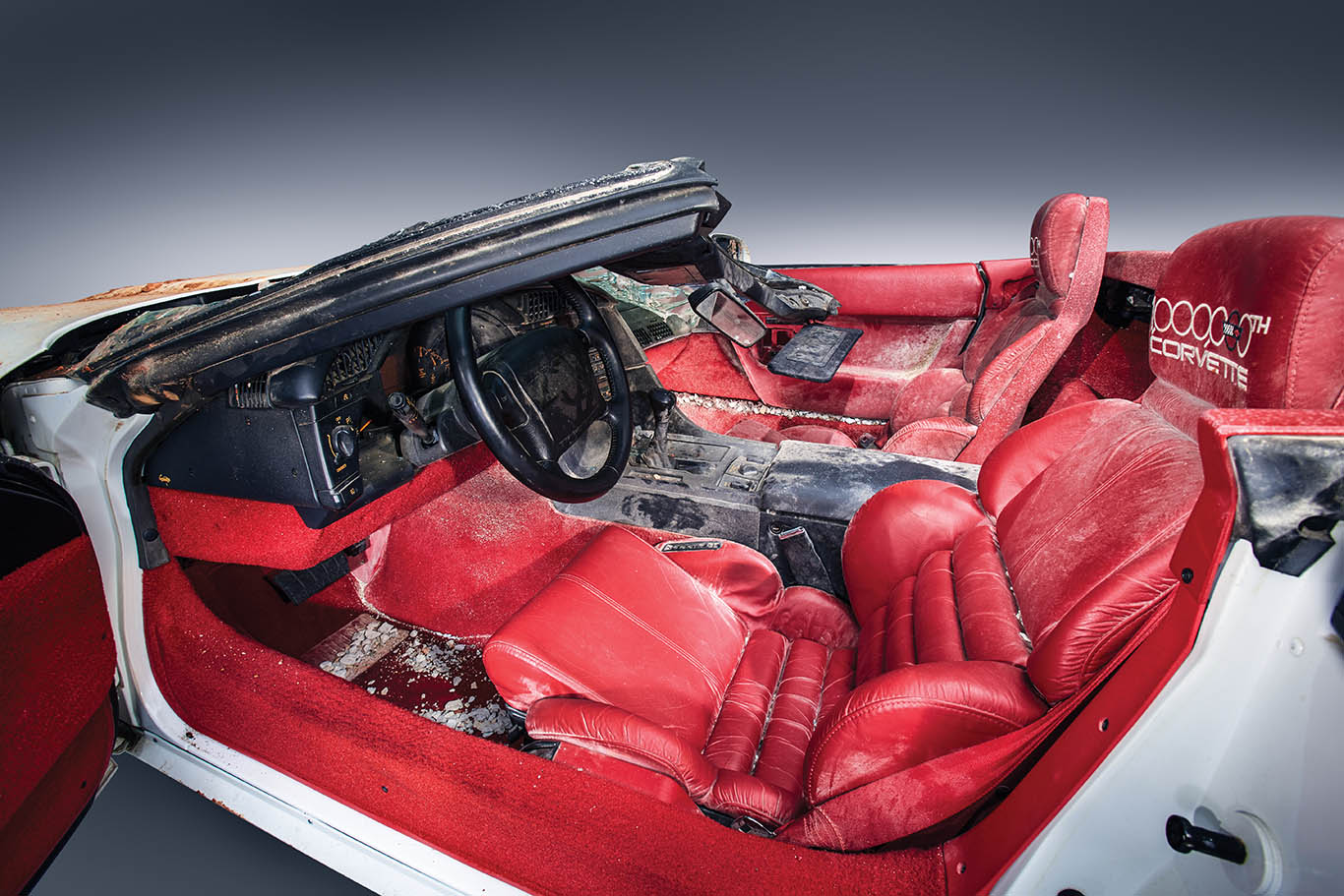

One of those casualties was the 1-millionth Corvette, a white 1992 convertible with a red interior and a special black top designed to match the original 1953 Corvette with that same color combination. The car had been much celebrated when it rolled off the Bowling Green assembly line on July 2, 1992, greeted by Corvette luminaries including former chief engineers Zora Arkus-Duntov and Dave McLellan, as well as a legion of automotive journalists and Corvette fans.

The majority of the eight Corvettes were too damaged to restore. The millionth Corvette came close. With its collapsed windshield, crushed bodywork, deep scratches and mudcaked surfaces, a typical insurance adjuster would have uttered the “T” word without hesitation. This milestone car was too important not to restore, however, so it was moved to the Design Center on GM’s Technical Center campus in Warren, Michigan, in an effort to bring the one-of-a-kind Corvette back to life. An undertaking too massive for a private restoration shop, this was definitely going to be an inside job.

“As the one and only 1-millionth Corvette, its preservation was important to us as the designers of the vehicle — and as Corvette enthusiasts,” says Ed Welburn, former vice president of GM Global Design, who retired in 2016. “The damage was significant in many ways; however, we have one of the most highly skilled specialty shops and teams of people in the industry, so they were fully prepared to take on the challenge.”

GM Design’s Mechanical Assembly and Fabrication Shops build concept vehicles and maintain GM’s historic vehicle collection. Approximately 30 craftspeople and technicians from Mechanical Assembly, along with GM Service Operations, were called into action.

Much of the capability of Mechanical Assembly — frame straightening, bodywork and paint — was applied to the restoration of No. 1 million. The team also had to deal with rock and gravel and dirt, and every time they took something apart, more debris would tumble out.

There was another obstacle, though. Every person who built the car back in the summer of 1992 had signed his or her name under the skin. Saving those autographs was difficult, because many parts that carried them were so damaged. It meant repairing rather than replacing, which also made the overall restoration more authentic. “We went to great lengths to preserve every autograph,” says David Bolognino, who directs GM Global Design Fabrication Operations.

The team had the autographs scanned, reproduced as transfers and placed on the replacement parts. Those replacements — hood, front fascia, lower panels between the front wheels and the doors, plus a number of ancillary supporting components under the hood — came from a Corvette of the same vintage and color, ensuring correctness of the parts and materials involved in the restoration.

One component was especially difficult to save. The right-side lower gill panel, with a single signature — from retired Bowling Green Assembly employee Angela Lamb — was too damaged to accurately scan. Lamb, now 57, worked on Corvettes for 30 years in both St. Louis and Bowling Green and was on the assembly line that day in 1992. She signed the part just before she installed it. “It was always an exciting day when a big car like that came through and we all got to sign it,” she says. “I had no idea it would be so significant.”

Chevrolet worked with the National Corvette Museum to secure a new signature from Lamb on the replacement part, so the 1-millionth Corvette is historically accurate down to the last signature.

The red seats with special one-off “1,000,000th Corvette” embroidery on the headrests were damaged but deemed irreplaceable, so they were restored, including a few replacement patches of carefully matched hide. Rather than replace the scuffed and scratched pad on the instrument panel, its soft cover was carefully removed and repaired to preserve the employee-signed structure beneath it.

The front sub-frame, too, was damaged in the fall into the sinkhole. It required time on a frame-straightening machine at the GM Tech Center Campus. Even the damaged wheels and Goodyear Eagle tires were reconditioned.