Piston Slap: When Every Musician Plays The Same Instrument?

DF writes:

Can we have a discussion on how or why different automakers/brands do the same thing? Take for example:

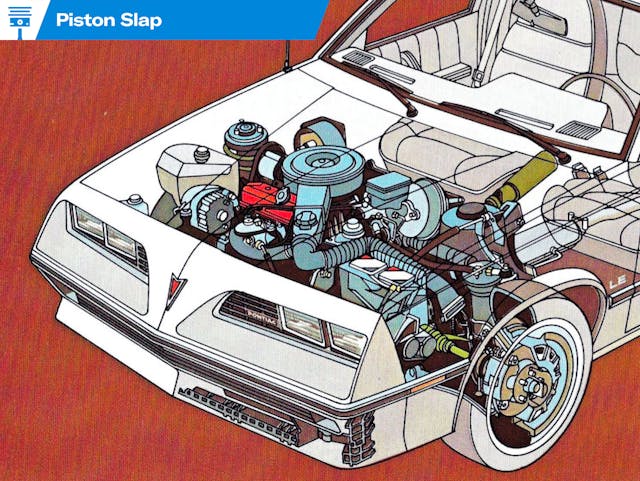

- The GM Iron Duke engine and the vehicles it has powered.

- The fuel injection systems of the 1980s cars to meet EPA regulations.

- The laggy turbos of that same time period.

- Or consider how cars like the Mustang II and ’80s Monte Carlos had front clips that were used in racing and kit cars.

Sajeev answers:

Oh, yes! There’s nothing that gets my blood flowing like a big picture discussion of the automotive industry, especially when put into historical context. It’s fascinating how individual vehicles, brands, manufacturers, or entire countries leverage the same resource to create their finished products, even if we only figure it out with archeology via part numbers, sales brochures, etc.

Take modern-day China, for example, as there has to be a “Briggs & Stratton”-like reason why so many of its gasoline-powered vehicles use a 1.5-liter turbocharged four-cylinder engine mated to a 7- or 9-speed automatic. I reckon this is a tale of partnership as old as Capitalism itself, or at least for as long as the Dodge Brothers supplied parts to other automakers.

Companies must leverage the work of others to maximize profitability and improve the long-term serviceability, durability, and enduring appeal of their brand. Unless you can summon up investors like Elon Musk does, of course. (While some Teslas used Mercedes switchgear, the company is famous for doing as much as possible in house, including seats.)

Your fuel injection example is a case study in leveraging the work of one vendor and spreading it across the board for better performance, lower emissions, and compliance with the federal government. The history of fuel injection goes back farther than our discussion of EFI (electronic fuel injection) in the 1980s, but many automakers leveraged the efforts of those who dedicated their careers to modern fuel injection. Bosch and Bendix sold a lot of EFI systems for automobiles during the Malaise Era, but not everyone was jumping on their bandwagon.

Ford (1980 Continental) and Chrysler (1981 Imperial) made EFI systems from scratch, if using hardware from established vendors. (I know that Ford systems of the era had Toshiba guts.) Neither were terribly innovative, just the right idea at the right time. Historically savvy members of the Hagerty Community will recall that Chrysler’s EFI scared off a lot of folks, and that applies directly to my comment about the “enduring appeal” of a brand.

While both Ford and Chrysler forged their own path, their EFI systems were leveraged within their respective brands. For example, a variation of the 1980 Continental’s throttle body fuel injection was standard fare in the cheapest Ford Escort just seven years later. Perhaps a parallel to Tesla’s battery technology is more apt, but this analogy is quickly going off the rails.

Your reference to the GM Iron Duke engine works on the same principle as EFI systems. The big difference is that its widespread use pertains to lowering costs and maximizing profitability, not cleaning up our smoggy air. As the old racing proverb goes, you gotta “run what you brung.”

Making the Iron Duke fit sideways and work with a front-wheel drive transaxle is easier than building a new sideways engine from scratch. But this isn’t a slam on GM, as Ford shrunk down the old Thriftpower inline-six to work in the Ford Tempo. And Chrysler looked to VW and Peugeot to power the all-new Omni.

Some automakers will die if they can’t share parts. Look at the Honda Prologue’s platform sharing with the Chevy Blazer EV. Both use GM’s Ultium architecture, but Honda didn’t even bother changing the shape of the roof pillars to give its EV a significantly different look than the Chevy. Why should they?

How many people cross shop Chevy and Honda dealerships these days, much less for an electric vehicle? All 621 of you can snicker when you walk into the showroom, but Honda’s officially entering the EV space with ease. It ensures it doesn’t go the way of Saturn during the SUV boom of the 1990s, and its technology won’t be a dead end because of its not-GM sized budget for new platforms. (Apparently, Saturn salespeople turned away many a loyal customer back then, and that was a hard pill to swallow for both parties.)

The same level of tweaking happens in garages and race shops around the world. It can be as simple as grabbing front disc brakes from a junked Ford Granada to OEM+ your 1960s Mustang, or as radical as Heidts’ re-engineering of the Mustang II’s front clip for use in a seemingly endless number of applications.

Be it a shadetree hot rodder or a corporation slapping Honda sheetmetal to a Chevrolet EV, this episode of Piston Slap can be distilled into one truth: Your final product is cheaper to design, more profitable to make, and more durable over the long haul when you leverage the work of someone else.

Have a question you’d like answered on Piston Slap? Send your queries to pistonslap@hagerty.com—give us as much detail as possible so we can help! Keep in mind this is a weekly column, so if you need an expedited answer, please tell me in your email.

***

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

The only time I “leveraged the work of someone else”, I got a failing grade and a note in my transcript telling all who would care to know that I’d been found guilty of Plagiarism.

Patent infringments happen to companies too. Like interval wipers, Ford, and the movie “Flash of Genius” that did a good job telling the whole story.

I was told Ford stole the Intermittent Wiper idea from Joseph Lucas

My Dad worked at GM, on the assembly line at Plant 9 in Pontiac, and submitted the idea for intermittent wipers around 1965. Union workers could submit ideas then, and if they were used, they would get paid. GM’s answer was that it would be too expensive and no one wanted it.

It is called scale.

All automakers do it yo save money. I have an Audi sitting here that has a VW version, Audi, and Porsche version. The trick is to offer these in different price ranges and different enough changes to get you to spend more money.

Some of this well some not do.

The Honda and GM deal was mostly to speed up Honda having a EV to offer and GM to gain more income. The cost of the EV programs are staggering and few will be able to go it alone. GM, VW and Toyota can afford it but even for them it is costly.

The Mustang II was pretty much bolted in much like a Corvair or even a Fiero. They are self contained. Street rod guys used the stock ones from junk yards and most most street rod companies offer their own versions test have better geometry.

The The Monte Carlo introduced the Rear Steer suspension. GM A and G bodies has these. Banjo Matthew’s took this snd applied to the NASCAR chassis. The platform already had a floor pan based on a 60’s Ford. The rear suspension long control arms they used are called truck arms as they came from a GM coil spring truck suspensions. All of these were made more for racing and made the cars turn better. They had to be based off stock parts but they were made full race.

Rear steer on the Monte means the steering linkage is behind the front axle line. Before that put the linkage in front of the axle line.

Early FI was pretty basic as it was expensive. Throttle body then to port now direct. It hot more and more expensive. But today things are not as much the same as to get better emissions they had get more specific per engine.

Same with Turbos. Today systems to work better and be more durable it is all specific.

If you look today most automakers have a volume division and a luxury, dome times a performance line. So you may see two or three variations of the same model. This is why GM off loaded Olds, Pontiac and Saturn as it cost more yo make and market these brands than they made. Only Vhina kept Buick alive and GMC supports most of these dealers.

Now why is there GMC? They make tons of money. The Denali line is like printing money. The average transaction price is nearly as much as Cadillac but on what is mostly just Chevy models.

A friend was walking out of a restaurant just as a guy was parking his nice new Cadillac Cimarron. Friend first said ‘nice car’, and the said “Cavalier, right?” This was of course before everybody had a camera in their phone – too bad

I don’t think fuel injection was needed in the 1980s to meet emissions. The trusty Quadrajet made it to 1990. I think it was more that the handwriting was on the wall, and they wanted to get these fuel injection systems into the field. As far as the Iron Duke, the industry goes where the customers lead them, and more people wanted (relative) economy over horses. GM made a lot of them. I saw one in RWD trim in a Firebird once, and wondered how much shame that driver felt every time the light turned green. The turbo is a tricky beast, and I don’t really think folks really figured them out until they started actually putting them in the field, much like EFI. The interesting thing about GM in the 80s is that if your car had a carburetor, it was most likely a feedback carburetor controlled by the computer. I am no expert, but other than some minor tweaks, the computer and electronics around that feedback carb were virtually identical to the EFI systems – so GM made some provisions for going either way depending on where the industry went

Correct, the feedback carburetor’s controls turned into the first EFI systems. But they weren’t nearly as emissions friendly as setups from 5-ish years later with two oxygen sensors, sequential fuel injectors, etc. not to mention the bump in fuel economy and torque curve improvements with Multi-Port injection.

The old LG4 305 qjet system wasn’t very sophisticated and quite tunable. The biggest handicap was it only added 18 degrees of ignition timing. So if you had 4 initial, it was a dog. Crank 14 initial into it and it drove quite well. TBI systems had a little more timing, but the same principle applies. More ignition timing made them run significantly better. Better fuel economy too.

I am a GM guy but I will be honest the Iron Duke was used for two reasons. One it was the highest mass produced 4 cylinder they made. Also it was the cheapest.

The OHC 4 was mostly used overseas and only Pontiac got to use them much. The turbos of this era even a Porsche had issues as we just did not have the oils to deal with heat and many were not water cooled early in the 80’s do bearing failures were common. Around 1985 and on the water cooling saved bearings and also Mobil One.

In the late 70’s plans were crazy as many companies were scrambling for economy and MPG. GM went to the all FWD plan accept for the Corvette. Even the Camaro and Firebird were set to go FWD.

The Corvette team was worried about loosing the V8 and looked at options like the Falconer V12 that was a 12 Cylinder Chevy an outsider company made. They also tested two 2.8 V6 engines in a Citation one in front and one in back to make a 12 cylinder AWD car. This car is in private hands today and it is quick as both V6 were modified.

As time went on emission and MPG was needed and we were losing power. So the first move was to the computer controlled Carbs. There was little you could do. They were not really fuel injection as there was never an injector. Just the adjustments were made by the computer.

These were not cheap so the next step was throttle body Injection that improved power and control. But by 1985 They decided the best move was to port injection, The cost was worth it. This brought a bit more power and much better MPG and quality of how it ran.

With Port injection came Mass Air systems that adapted to changes. It kept the system running better over the life of the car. The closed loop system was ok but there was no adaptability. The after market ate up the Mass air as this let them offer modifications and no reprograming.

The 80’s was a decade of change that was a fight between what worked best and costs. It took over 10 years but they finally adopted what they should have from the start. This was a auto market wide deal.

People were not so much wanting Economy over power it was just the price you paid in 1980. They fixed this by 1990 and later.

Keep in mind while these early 80’s systems are abysmal today they were improvement over much of what we had in the 70’s. The Thermoquad and Lean Burn systems were train wrecks. Also the other makers had their faults too.

Some of the fastest cars were a Trans Am that really had little power and a Dodge Little Red Express. That is where all this started.

Just look at the 84 Vette with the Cross Injection. Not good in fact twice as bad. But 85 Port injection. 8 times better.

The development of fuel injection wasn’t entirely linear – Cadillac had multi point electronic fuel injection in the mid 70s, but less than 1% of folks took that option. Throttle body and feedback carbs ran pretty much neck and neck in the early 80s with multipoint reappearing on more performance oriented applications. Both TBI and carbs hung on into the early 90s and probably have usage spans that are fairly overlapping.

I have always avoided the 84 Vette, but always wondered if Crossfire was bad, or just no one knew how to work on it

There was nothing wrong with Crossfire injection, people just hated it because it wasn’t what it replaced nor was it as good as what replaced it.

The iron Duke is nowhere near as good as the Iron Maiden. :^)

Did anyone catch the number of that beast? 👍

Hyper, You have a great automotive background but you really need to spell check your work so you don’t come off as illiterate.

My thoughts on the subject (not in any particular order} Using the iron duke, (also called tech 4 when fuel injected). That was a great old (1/2 of a pontiac v8) which hails from the 60’s! They also had a super duty program with high performance parts.

Pontiac was always a thorn in chevrolet’s side and one of the reasons they were canned. They had a lot of tech that didn’t make it to the public (60’s ohc engines) and remember their 2 seater prototype that scared the pants off of chevy?

Fuel injection won out because of better metering and less parts. The quadrajet alone has 170 parts. And they and thermoquads got a bad rap because people didn’t know how to work on them. Tuned properly, they could give great performance and decent economy. When the quadrajet was computerized, only the front barrels were affected.

Turbochargers were used in the 60’s in Corvairs and Olds Jetfires, Both very potent but just like early Corvette and Pontiac (50’s) fuel injection, they were misunderstood and taken off for a four barrel.

Many companies supplied turbochargers in the 60’s and made them work, Ak Miller, Turbonique, Accel, etc.

Buick continued developing turbos and when technology gave us better computers, distributorless ignitions and sequential fuel injection, we received a 1984 Buick Regal that outran a Vette in the quarter mile and continued to do so thru 1987! (Remember “We Brake For Vettes”) and by the way none of the buick’s turbos were water cooled. Yes the oils did get better but the key to keeping them running was not to rev them up and shut them down and also to let them run for a few minutes to cool the turbo off. An easy thing to do but most people would rather blame the turbo.

The turbocharged Pontiac Hyper mentioned was the J2000 series (sunbird, skyhawk, starfire). In the mid ’80s, they received a 1.8 brazilian motor (opel?!) and it was not a good turbo platform.

The crossfire injection was used on the ’82 Camaro and the Vette. Short coming of them was typical GM. Bean counters ruin everything performance. They also could be made to run very well if you knew what you were doing, just not the way the factory was putting them out. Yes the tuned port was easier to tune.

The best one about mixing parts and getting it right, The 1989 Turbo Trans Am used the Buick turbo 6, One of the few times GM did something right. Performance and Economy.

One of the most technology and parts user/borrowers was AMC. 25 years ago I had a 84 Jeep Grand Wagoneer, back when AMC owned Jeep. The full size SUV one with woodgrain sides. While it had an AMC 360 V8 and AMC model 20 rear axle, it had Motorcraft ignition, alternator and carburetor, Saginaw steering column and box, Dana 44 front axle, Chrysler 727 automatic trans, Delco booster, master cylinder and brakes, and more I can’t recall right now. It was truly “American” motors as they utilized parts from all over the US auto manufacturing sources.