GT Whisperer: The Michigan shop keeping Ford’s supercars on the boil

We’d all be lost without a congenial mechanic to keep our lawn mowers and garden tillers in tip-top shape. Rich Brooks, a kindred spirit at the opposite end of the mechanical spectrum, specializes in American supercars. If your 2005–06 or 2017–20 Ford GT needs anything beyond a lube job, Brooks’s GT Garage in rural southeast Michigan is your go-to destination.

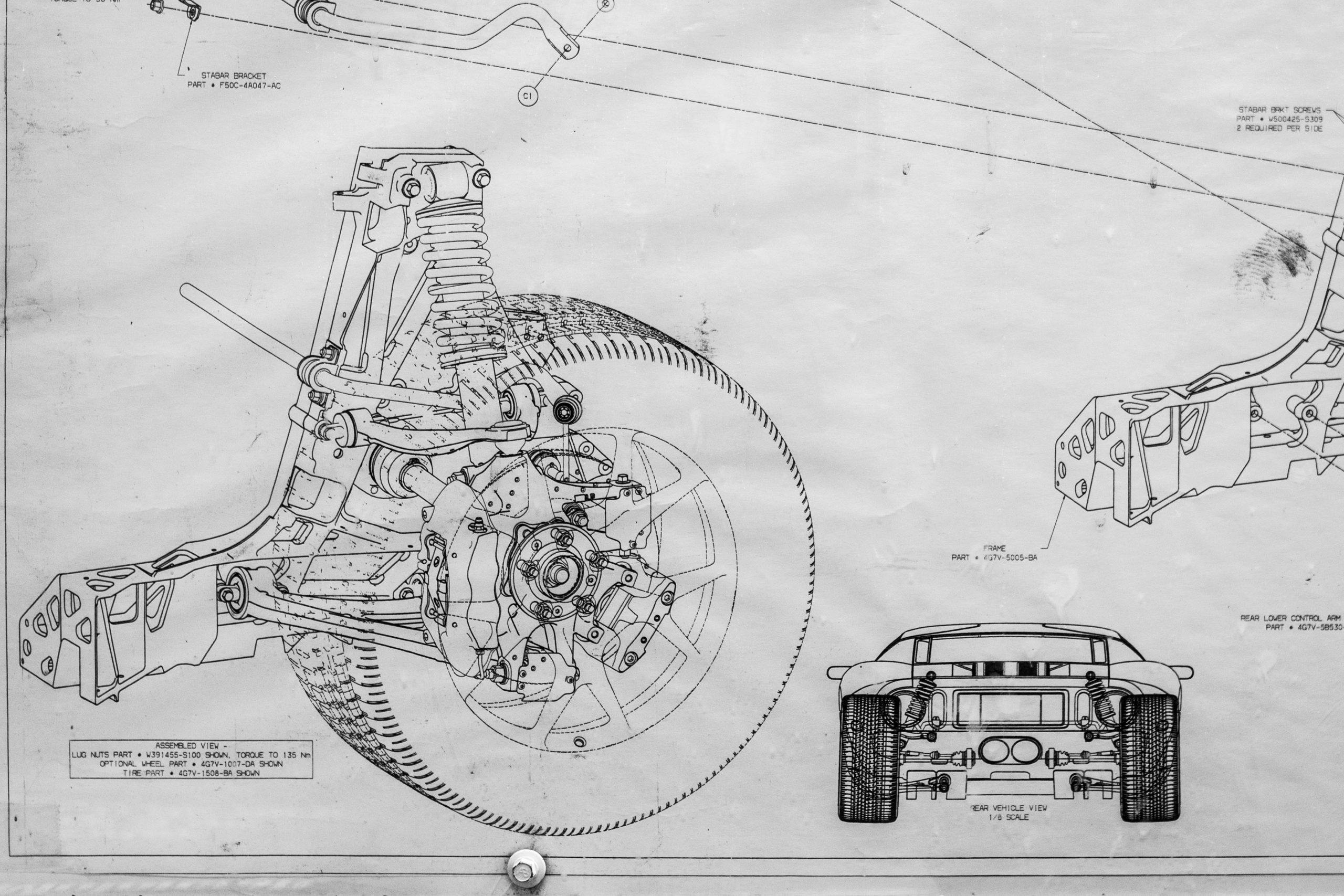

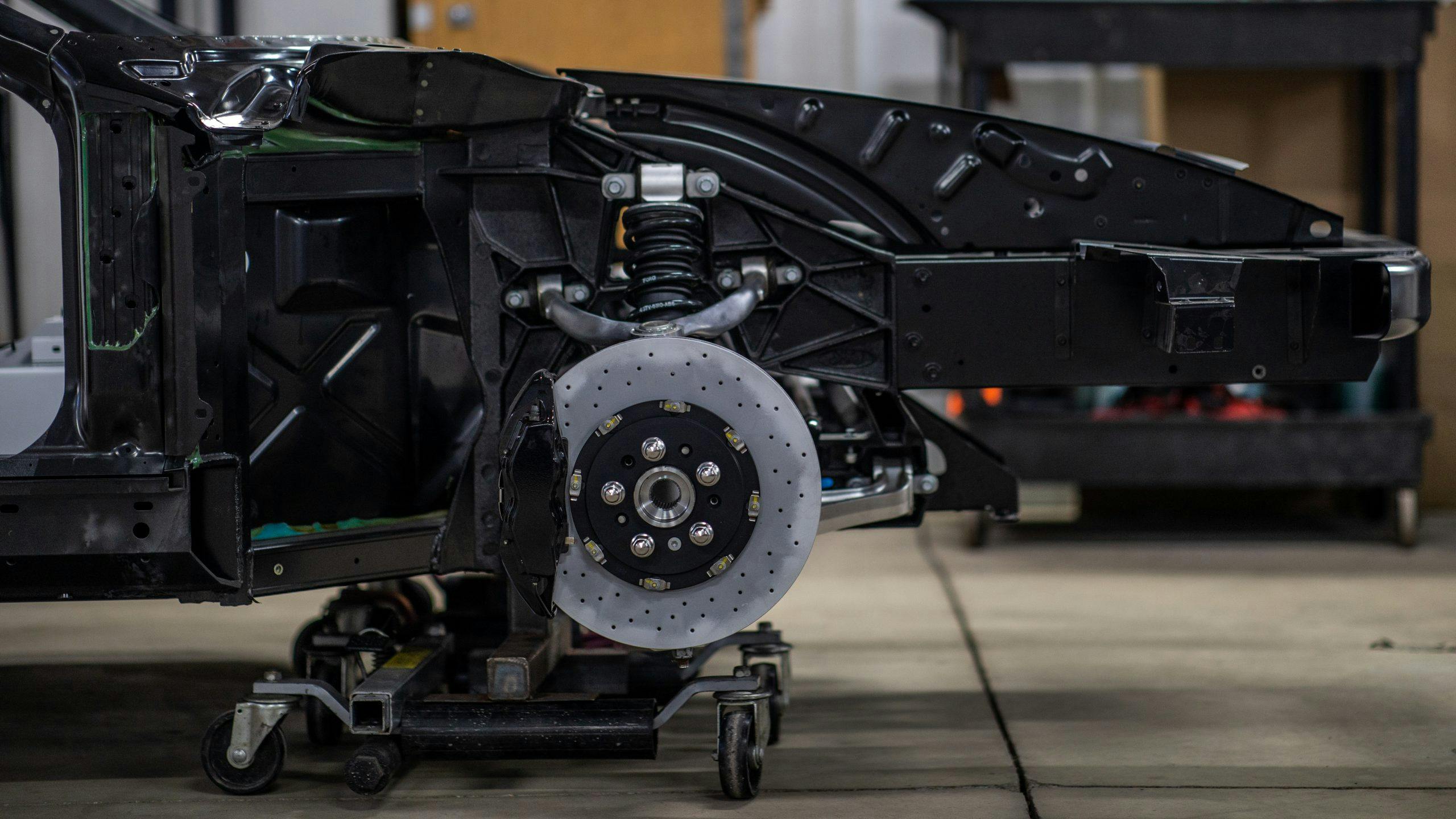

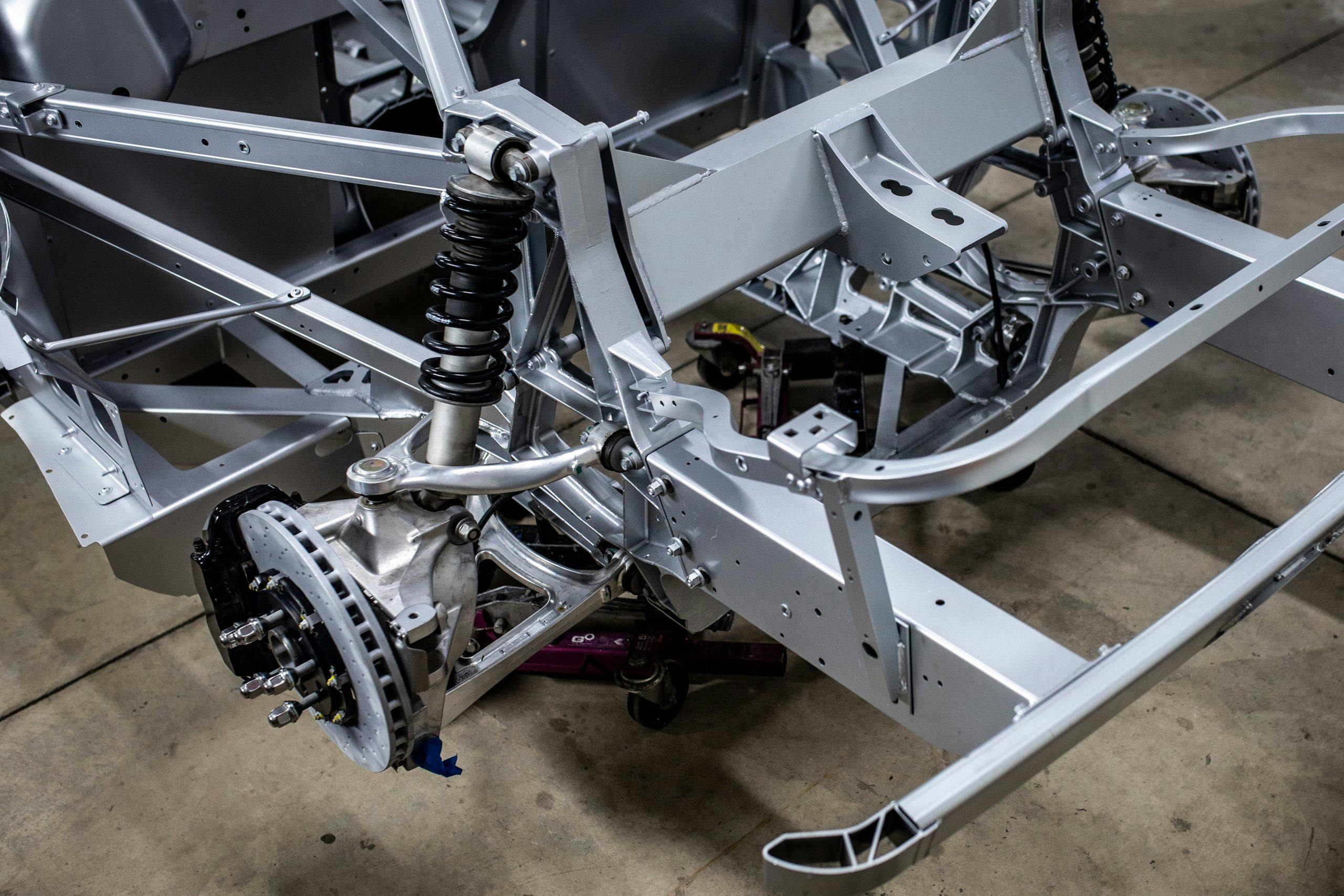

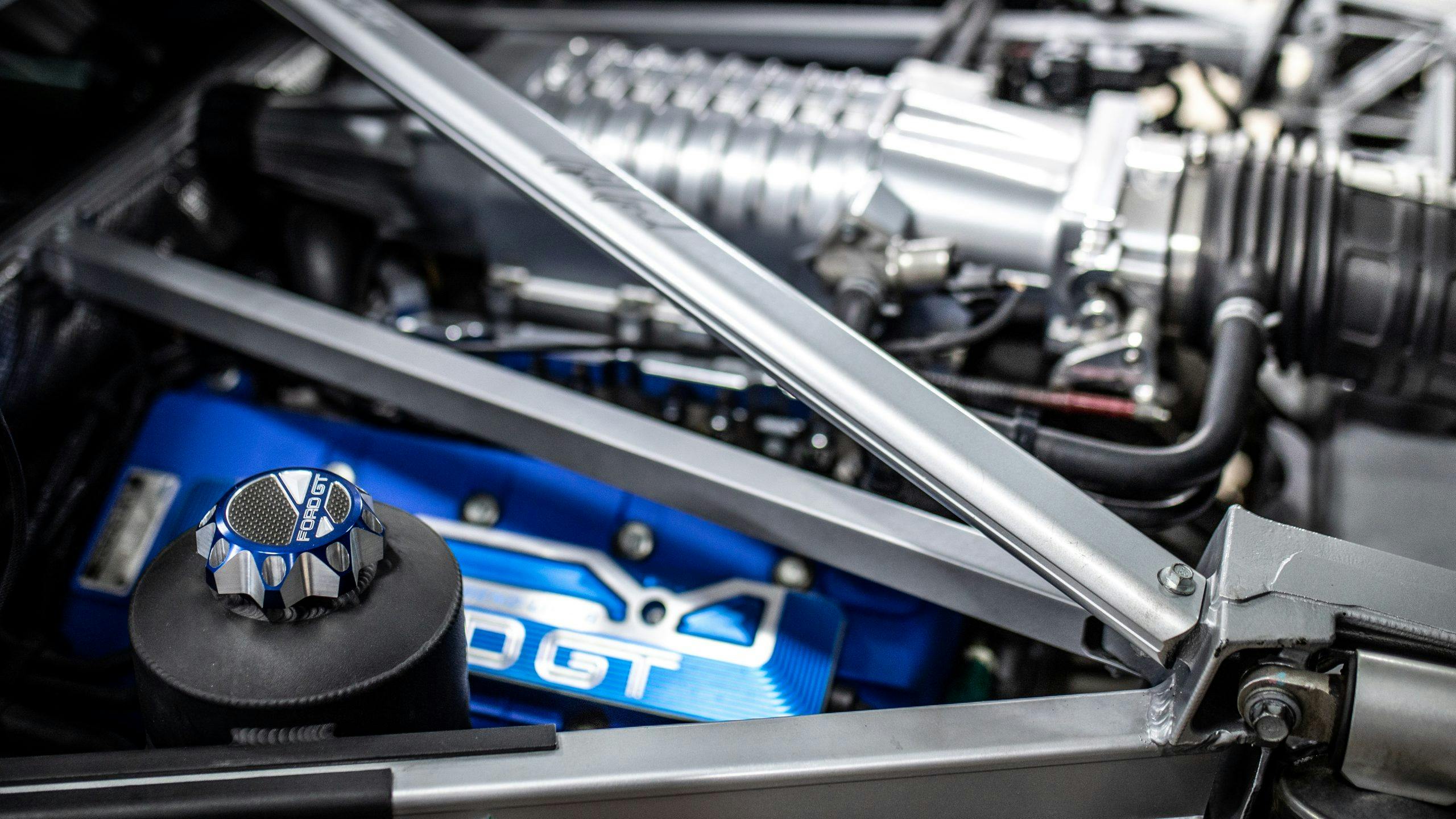

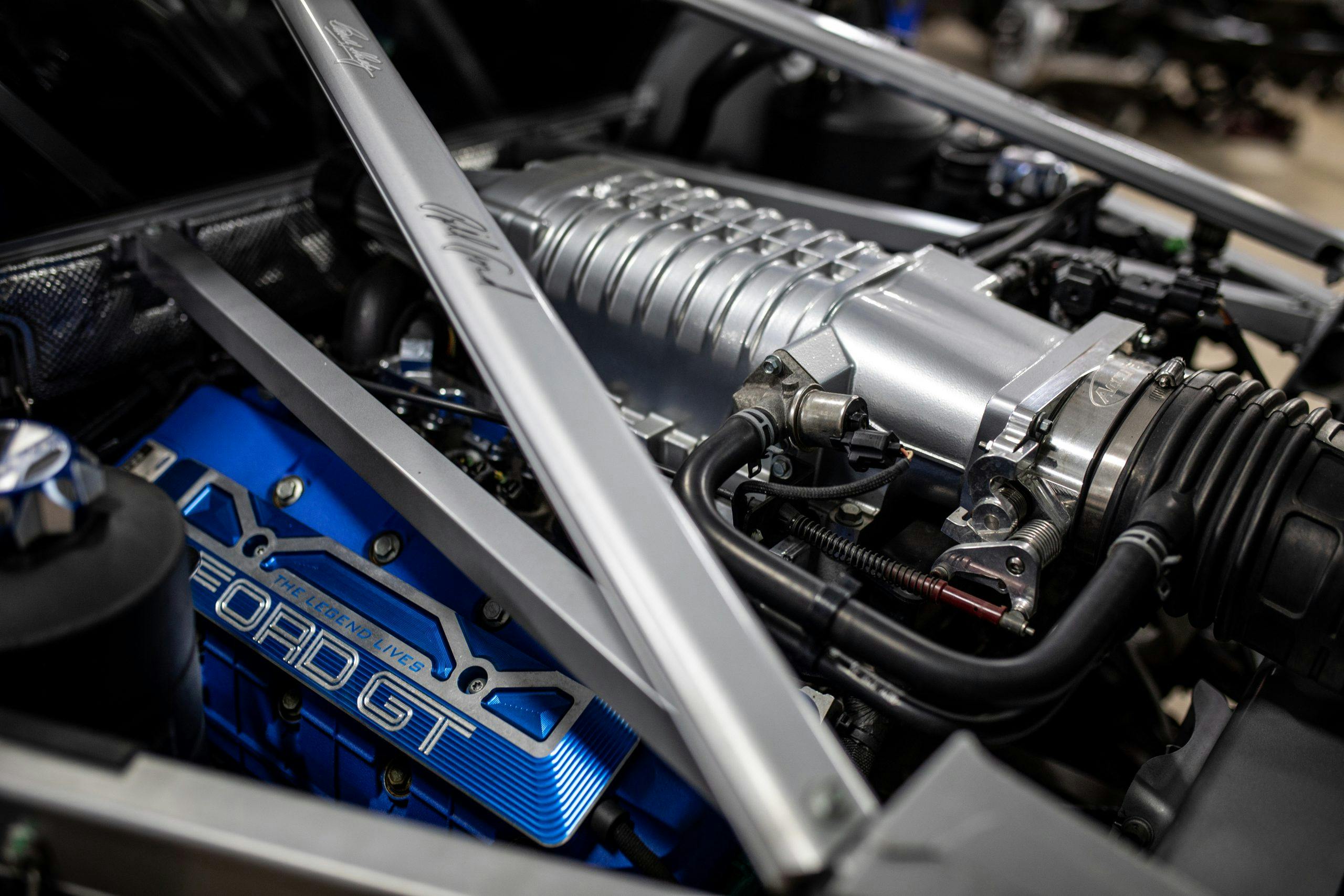

Ford’s revival of the Le Mans–conquering GT40s from the 1960s are the most exotic and expensive sports cars ever conceived in America. Powered by a supercharged 5.4-liter, 550-hp DOHC V-8, the 2005 edition started at $139,995. Just over 4000 first-gen GTs were built by Mayflower Vehicle Systems and Saleen Special Vehicles under the auspices of Ford’s Special Vehicle Team (SVT). The mid-engine layout, Ricardo six-speed transmission, low-drag bodywork, and aluminum-cum-magnesium chassis provided the ideal platform for analog performance.

The second-generation GT is a more ambitious blend of molded carbon fiber, structural aluminum, and Gorilla Glass. This time, Ford opted for an EcoBoost V-6, initially rated at 647 horsepower, bolted to a Getrag seven-speed dual-clutch automatic transaxle. Upholding their lineage, a pair of these GTs in LM GTE-Pro trim finished first and third in class at the 2016 24 Hours of Le Mans. Since 2017, about 1000 of these GTs have been sold, for roughly $500,000 apiece.

Brooks established his garage complex less than 10 miles from his birthplace. “My dad began coaching my mechanical inclinations at the bicycle stage,” the bright-eyed 40-something wrench explains. After earning an associate’s degree at Henry Ford College in Dearborn, Brooks began his career at Roush Industries as a technician-mechanic in 1995. That was an especially rewarding time, because John Coletti ran Ford’s SVT department full-throttle, and Roush was contracted to execute many of its projects. Brooks personally stuffed a Contour V-6 into a Ford Focus for Coletti. He helped develop the 2003 Mustang SVT Cobra and the second-generation F-150 Lightning pickup. His luckiest stroke was being present in 2003 for the creation of the first Ford GTs under Coletti.

After a dozen or so years at Roush, Brooks felt the urge to steer the skills and knowledge he’d acquired in a fresh direction. In 2008, he began a double-shift routine—clocking in at Roush by day and getting his fledgling GT Garage up and running during evening and weekend hours. By 2010, his GT customer base had grown sufficiently to enable snipping the Roush apron strings altogether.

What resembles a classic red barn on the outside houses nearly 5000 square feet of space for repairs and storage. A dozen or so free-range chickens help the complex blend into the farming-oriented neighborhood.

Brooks’s shop is clean enough for surgical procedures thanks to work habits inspired by his Army veteran father, whom he describes as a clean freak. “Frequent cleaning is essential in my work,” Brooks says. “I sweep work areas every time a car leaves and power-wash the floors once or twice a year.” White-finished metal walls ricochet illumination provided by more than a dozen fluorescent light fixtures. The concrete floor is as smooth as a sheet of plate glass, interrupted only by the well-worn paths of GoJak wheel dollies.

Since Brooks’s home is only a short hike from his shop complex, there are no bathroom facilities, though creature comforts include Wi-Fi, a wall-mounted TV, Bose satellite radio typically wailing ’80s and ’90s rock, and a stocked fridge.

Acknowledging that there are only so many tunes a one-man band can play, Brooks subcontracts paint jobs to focus on mechanical work. He also relies on a web of collaborators for heavy collision repairs, machining, and full engine overhauls; GT transaxles are so intricate that they’re generally replaced rather than rebuilt when they suffer major internal wounds. Alongside an array of hand tools, Brooks has a Miller TIG welder, drill press, hydraulic press, band saw, tire changer, and four-wheel alignment system. A new tire balancer tops his wish list.

A pair of two-post lifts reside in the main work area, and three four-post lifts stash inventory in the storage room. The standby list there includes Brooks’s high school ride (a 1987 Ford Ranger stuffed with a 302-cubic-inch V-8), his wife’s 2003 Thunderbird, his 2014 Shelby GT500, a 2014 F-150 SVT Raptor pickup, one of only four remaining GT workhorse prototypes, and a dozen-plus customer cars. Brand-new body shells bought from Ford at attractive prices are on hand to resurrect first-gen cars seriously damaged in crashes.

Because the second-generation GTs are still under-warranty newbies, Brooks focuses on 2005–06 cars. “With over 2000 owners on my client list, I’ve worked on at least half of the production run,” he notes. Supplementing his base of wealthy car enthusiasts, Brooks services GTs owned by Ford royalty: Edsel Ford II; Henry Ford III; the company’s current CEO, Jim Farley; and Multimatic’s president and CEO, Raj Nair.

Instead of using an hourly shop rate, Brooks quotes projects on a fixed-cost basis. For example, removing and replacing a GT’s front fascia runs $600. “After customers submit a list of what they want done, I respond with a total cost analysis to avoid surprises,” Brooks says. Additionally, he has flown all over the country to assess for-sale GTs for prospective buyers.

One of his most fruitful relationships is with ex-Ford designer Camilo Pardo, who operates studios in Detroit and Southern California. Working with customers, Brooks and Pardo have built a dozen Signature Series Ford GTs—including Brooks’s personal car—with performance upgrades and stunning exterior treatment. Paint jobs mimicking the most memorable Le Mans racers are the preferred schemes to date.

If there’s one thing Brooks doesn’t put much effort into, it’s selling himself. Instead, he simply attends annual gatherings for members of the Ford GT Forum in order to stay in touch with current clients and to meet new ones. Framed posters from these family reunions adorn the walls of the shop.

Customer satisfaction is another reason why Brooks spends little time marketing his skills. “Ninety-eight percent of my customers are happy with the service I provide,” he says. “While pleasing everyone may be impossible, I haven’t stopped trying to win over the remaining 2 percent.”

I live in Mexico City and I have a 1997 Ford GT which just had a crash damaging the engine cover at the right quarter panel area, as well as the right hand rocker panel, do you also repair body parts, it is possible to get body parts, can you help me so I can repair my Ford GT. Thanks in advance