Finally solving a hard-starting problem

A number of things have happened at Chez Hack recently. First and foremost, as I mentioned in passing a few weeks ago, I somehow wrenched my back on one of the RV trips. It wasn’t like the back injury I had 15 years ago, where I moved a 32-inch CRT television and installed a water heater in the same weekend, resulting in years of sciatica and low back pain that finally leveled out with time and physical therapy. This time I really have no idea what I did to anger the spinal gods. An X-ray showed nothing more than some normal age-related bone loss between L1 and L3, so the doctor is calling it a muscle strain. But it’s severely crimping my style.

I’ll do nothing for several days and it’ll get better, then something small like backing the Lotus into the garage and turning around to look when doing so will set it off. It’s not remotely on the level of other issues plaguing the world, but it’s severely interfering with my ability to, well, to be me. For example, I’ve sourced a replacement alternator for the Winnebago Rialta, but I’m hesitant to do the contortion necessary to crawl under the RV’s nose and install it right now. I’ll get there. Just don’t count on me for any engine swap or transmission removal tips anytime soon.

The second thing is that, after an eight-week wait, BringATrailer.com finally sent me a draft of the listing for my friend Chris’ 1972 BMW 2002tii, the second of the two “mitzvah” BMW 2002s that I’m helping to sell (her deceased husband was the original owner). I’ve written previously about the lengthy BaT process that requires you to fill out information about the car in text fields in an online form—condition, modifications, recent repairs, non-functional items, etc.—and then wait months for BaT to turn that into a description that’s so poorly written it’d cause any 8th grader to get a D on a middle school English assignment.

I, and many others, lampoon BaT for the cliché “house voice” phrases like “power is delivered to the rear wheels,” but having worked at Bentley Publishers and been part of a team that wrote repair manuals, I do understand the policy of using a bland voice that’s uniform across many writers. I also understand the legal necessity of using words and phrases such as “reportedly” and “according to the seller” to insulate BaT from liability. But the thing that drives me absolutely crazy is that BaT’s descriptions often intermingle specifics on the car that’s for sale with things that apply to all cars of this model, and often pick out elements that are trivial and elevate them inappropriately in importance, resulting in a word salad that, if you read it in an ad anywhere other than BaT, would make you think, “This seller doesn’t know anything about this car.”

For example, the draft description of the 2002tii had the following sentence in the second paragraph: “Features include a polished fuel-filler cap, bright window and beltline trim, chrome bumpers with overriders, round taillights, and pop-out rear side windows.” First, why would anyone selling a car highlight the fuel cap, polished or not? Second, the “bright window and beltline trim” was picked out of a lengthy description I’d supplied BaT on the condition of all of the brightwork on the car, but when it’s called out like this as a “feature,” it’s so out of context that it’s not even clear what’s being described. Third, all 1968–73 BMW 2002s have chrome bumpers and round taillights, and all 2002s have pop-out rear side windows. I pointed all this out to the auction writer, and the only modification he deigned to make was moving the polished fuel-filler cap to the end of the sentence. Another sentence reads, “The car is equipped with Bilstein shocks and struts, and braking is handled by front discs and rear drums.” This, again, shows the confusion between a modification (the Bilsteins) that are on this car versus the disc/drum configuration that all 2002s have. When I requested that these and other things be grouped into like paragraphs, the response was a terse quoting of BaT style and format guidelines. As I explained in a previous story, the best you can do is to write your own description and paste it in as the first comment (or comments; the comment length limit is about 850 words) when the auction goes live. By the time this piece runs, the auction will have closed, but you can see it here (the car sold for $35,752).

But I digress, as the main thing I want to talk about this week is finding a surprising cause of a hard-starting problem.

A few years ago, I wrote a detailed piece about troubleshooting a no-start condition on a carbureted car with a mechanical fuel pump. In fact, the patient was the same car—“Hampton,” my 49,000-mile 1973 BMW 2002. If there’s fuel in the float bowl, the ideal situation is that you start a carbureted car by mashing the gas pedal once or twice to have the accelerator pump squirt some raw fuel down the throat and to allow the choke to rotate closed and have the fast-idle screw settle on its place on the little cam that rotates along with the choke, then crank the engine, and vroom. Unfortunately, carbureted cars that have been sitting often have dry float bowls, and the mechanical fuel pump often has trouble priming the system and filling the bowl. In the story mentioned above, I talked about how the trinity of a dry float bowl, dry-rotted fuel lines, or a loose clamp causing the mechanical fuel pump to suck air rather than fuel, and the weakness of the diaphragm in a decades-old mechanical fuel pump are usually the cause of hard starting after sitting. Replacing the mechanical pump with an electric one eliminates the priming issue, but it also changes the look of a vintage engine compartment, something I didn’t want to do with such an original low-mileage car. I also talked about how, on Hampton, moving the fuel filter from before the fuel pump to after it made a huge difference. I thought I was done with the problem.

I was, of course, wrong.

Hampton had been in storage all summer in the warehouse in Monson, Massachusetts, on the Connecticut border where I rent space. Last week, I realized that I, who owns three BMW 2002s, had none of them here at my house to drive through this autumn (the “mitzvah” 2002tii had been occupying precious space in my garage instead), so I drove my BMW M Coupe (“the clownshoe”) out to Monson and swapped it for Hampton. Or I tried to—despite cranking it so much that I began to run the battery down, Hampton was maddeningly difficult to start. I thought this was just a float-bowl-priming issue, but surprisingly, it then repeated the hard-starting problem when stopped at a liquor store on the way home (I spent an hour chatting with a guy who admired the car), and it did so again the following morning. So, the primary cause obviously wasn’t a dry float bowl. Something else was clearly still amiss.

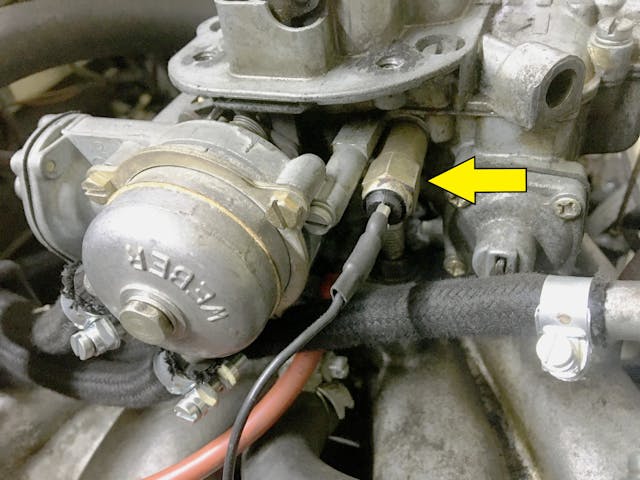

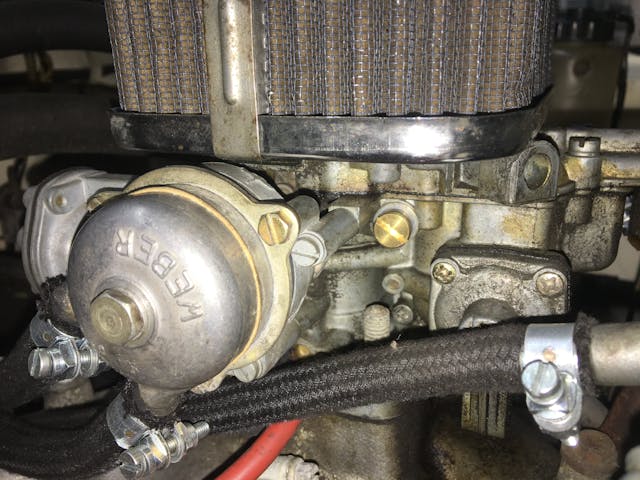

Every carburetor I’m aware of has an idle jet, and some carbureted cars have a little idle cut-off solenoid to stop the flow of fuel to the idle jet and help prevent run-on (dieseling) after the ignition is shut off. The solenoid is typically a housing about 1.5 inches long and about as thick as your pinkie that has a little plunger that retracts when the solenoid is fed 12 volts. When the ignition is shut off, voltage is cut to the solenoid, and the plunger returns to its rested extended position and prevents fuel from flowing through the idle jet. A few years ago, I was at the BMW “Vintage at Saratoga” in upstate New York and helped a guy troubleshoot a hard-start problem on a 2002. The car would start if you held the throttle partially open, but it would die immediately if you took your foot off the gas. I could hear its idle cut-off solenoid click when I connected and disconnected the wire, so it appeared to be working. I also pulled the solenoid out and inspected the idle jet to make sure it wasn’t plugged. All appeared fine, but symptomatically the solenoid still seemed to be the most likely suspect. The fellow reported that after he got home, he replaced the solenoid with a new part and the problem went away.

So, with that in mind, I looked at Hampton’s idle cut-off solenoid. As I did with the fellow’s car in Saratoga, I turned on the ignition and disconnected and reconnected the wire to the solenoid and verified that I heard it click. I then unscrewed the solenoid from the carb, reconnected the wire, touched the casing of the solenoid to the body of the car to ground it, and verified that the plunger extended. Lastly, I pulled out the idle jet and verified that it wasn’t clogged. I put it all back together. It made no difference; the engine was still very difficult to coax into ignition.

Like many cars of this era, Hampton has a partially de-smogged engine, with a Weber carburetor and some (but not all) of the myriad of vacuum-control solenoids and deceleration dashpots disabled. The idle cutoff solenoid was wired directly to the hot side of the ignition coil by a previous mechanic. This is a common way to get ignition-on power to engine compartment components such as this, but it’s generally not a good idea, as you’d hate for the wiring of an accessory to interfere in any way with the coil voltage. So, rather than replace the cut-off solenoid with another one, I ordered an idle jet holder that eliminates the solenoid entirely.

When it arrived, I pulled the idle jet from the solenoid, slid it into the end of the holder, screwed it into the carb, and made sure the connector that had been powering the solenoid wasn’t grounding anywhere. I got into the car, pumped the gas pedal once, and turned the key.

The car started instantly. I checked it again the next three mornings and got the same result.

Well then!

I can’t really say whether the problem was with the solenoid itself, with its electrical connection, or with the connection somehow interfering with the coil, but sometimes you just need to take the win.

So, if your car has an idle cut-off solenoid, and if it experiences hard-starting problems, put it on your list of things to check. Check twice if you’re in Saratoga. Or Monson. Or in my garage. Or in the parking lot of the liquor store.

***

Rob Siegel’s latest book, The Best of the Hack MechanicTM: 35 years of hacks, kluges, and assorted automotive mayhem, is available on Amazon. His other seven books are available here, or you can order personally inscribed copies through his website, www.robsiegel.com.

Congratulations on the sale. One down a dozen to go?

My electrical engineering knowledge is rusty but I feel like the voltage source of the solenoid is a contributor to the problem. Basically you have two loads in parallel from the same voltage source and the resulting current draw on each leg. Then solenoids have in rush current to activate and coils back feed the positive side when they fire. That back feed is what is used by current sensing tachometers used in the 60s and 70s. Back feed is the wrong word but if you use a scope, there is a specific wave pattern seen on that wire when the coil fires. It just seems like a recipe for issues with both loads. Not sure if the car has electronic ignition or points but ballast resistance to the coil needs to be considered and can cause a different response between cranking and running. There are a lot more options these days to get high quality weather sealed small relay/fuse boxes to provided switched power sources underhood. A relay needs so little trigger current that the coil positive can still be used with the added benefit that the relay shields both loads from each other through the feeds back to the battery. The battery is a giant capacitor and helps to absorb all of the noise and spikes in current draw. Think of it like flushing 3 toilets and water stops coming out of the shower. The battery acting as a capacitor provides reserve so the shower stays running when all of the toilets are flushed. It is a fascinating problem to resolve and understand the science behind what is really going on. A relay is just an idea to rule out a possibility but seems directionally correct. I enjoy reading the comments to gather other ideas and experiences.

“Every carburetor I’m aware of has an idle jet” – then you’re not aware of SUs and Strombergs? Who needs a separate idle jet – just one more thing to go wrong, as is well proven in your piece.