LT6 Breakdown: The Z06’s 670-hp V-8 is a landmark achievement

America’s traditional performance path starts with a smoking heap of piston displacement under the hood. With the arrival of the 2020 Chevrolet Corvette, a.k.a. C8—a mid-engine first, after 67 years of front-motor Vettes—a radically different strategy emerged. To endow Chevy’s halo car with true supercar verve, the traditional combo of pushrods, long-stroke geometry, and cast-iron block was ditched to create the technologically advanced powerplant presented here.

Later this year, those wise enough to bribe their local dealer with an early deposit will take delivery of a Corvette Z06: 670 hp and a rousing, 8600-rpm redline. The LT6 V-8 makes it happen. Let’s dive in.

Gemini: The new small-block

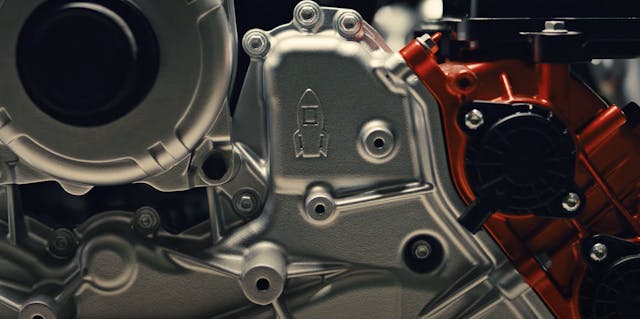

If you’re lucky enough to see a ’23 Z06 in person, ask to peek under the hood. The 54 rocket insignias GM engineers hid around engine represent the “Gemini” code name used during the project’s eight-year development. The symbol carries multiple meanings. Early Corvettes were admired and driven by the first NASA astronauts. Also, Gemini is Latin for “twins,” a nod to this engine’s double overhead cams and prominent pair of intake plenums.

Only one dimension—the 4.4-inch cylinder-bore spacing—made the leap from the five previous generations of Chevy small-blocks. While the LT6 shares no parts with its predecessors, that carryover spacing provides a historical link to engines that have powered Chevrolets since 1955. The 104.25-millimeter bore is one of the largest cylinder dimensions ever used in a Chevy small-block, while the 80-millimeter stroke is one of the shortest. The combination yields a modest 5.5-liter piston displacement, which also happens to be ideal for the Corvette C8.Rs that compete against Porsches and Ferraris at the 24 Hours of Le Mans. The LT6’s deck height (the distance from crankshaft center to cylinder-head sealing surface) is ten percent shorter than the deck height of the base C8’s 6.2-liter LT2 V-8. The new block’s mass is 16 percent lower. Dividing the Z06’s 670 hp by its 333 cubic-inch displacement delivers a nice round ratio of two horsepower for every cubic inch.

Flat-crank fashion

The LT6’s signature feature is a crankshaft with four throws located in a single plane. This leaves those throws 180 degrees apart—the layout is colloquially called “flat”—versus the usual 90 degrees of a traditional, “cross-plane” V-8. This arrangement is standard in racing and Italian supercar V-8s but rare in American engines. A century ago, Cadillac moved from 180-degree crankshafts to 90-degree units in order to reduce shaking forces, and most other V-8 makers quickly followed suit.

Flat cranks bring significant advantages, one of which is significantly less rotating inertia, especially when a short stroke is part of the deal. Perhaps the biggest benefit is that flat cranks enable spacing the four exhaust strokes in each of a V-8’s two cylinder banks 180 degrees apart. Thanks to LT6’s ultra-short stroke and light connecting rods, this crank’s counterweights are lighter and its rotating inertia is significantly reduced.

The loping sound commonly associated with American V-8s comes from how some of those exhaust strokes are staged at 90-degree intervals. Flat cranks increase that spacing to 180 degrees, maximizing scavenging—the effect where exhaust gas from one cylinder actually sucks spent gases out of an adjoining cylinder’s exhaust port, aiding flow and efficiency. The Z06’s tri-Y exhaust headers further exploit this effect. The evenly spaced combustion pulses also benefit intake air flow.

Flat-crank V-8s respond righteously to every jab of the throttle; their firing pulses, which alternate between banks, help give these engines a banshee wail at high rpm. To make the LT6’s crankshaft as light as possible, GM bores unnecessary metal out of the rod and main bearing areas. While flat-plane engines offer increased vibration, Chevrolet engineers claim this shortcoming has been minimized by securely attaching ancillary equipment such as the alternator, and by carefully tuning powertrain-to-chassis mounting systems.

During development, GM engineers discovered that vibration was causing the LT6’s oil filter to unscrew itself. That issue was remedied by locating the filter element inside a substantial aluminum canister, instead of the more common spin-on arrangement. The LT6’s eight-quart, molded-plastic oil-storage reservoir is also mounted to the block through rubber isolators, to protect it from vibration damage.

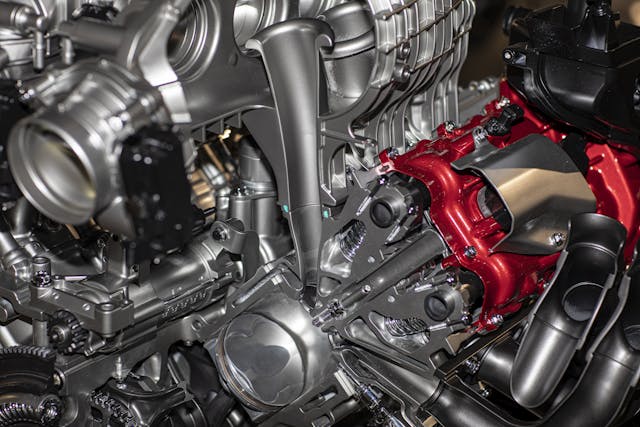

Doing the splits

The LT6’s 90-degree cylinder block is split horizontally, assembled from two separate castings that mate at the crankshaft centerline. The cylinder case and the oil sump are both made of A319 aluminum alloy, which is heat-treated after casting. A special talcum additive smoothes areas in touch with coolant and oil. Four vertical bolts secure each of the five main-bearing caps. The crank is forged steel, and the Austrian-sourced connecting rods are forged titanium. Super-short-skirt, forged-aluminum pistons are supplied by CP Carrillo, a highly respected racing-parts vendor. Piston rings and cam followers are coated with a friction-reducing material made of diamond-like carbon.

Shrunk-in-place cast-iron liners assure long-haul cylinder-bore durability. They’re arranged in a “Siamese” configuration—the outside of each adjoining liners touch—so there’s no lateral coolant flow except through small, drilled passages near the block-to-head interface.

The LT6 has a multi-purpose intermediate shaft rotating between the cylinder banks just above the crank. This shaft is driven off the crankshaft by short chain, and it, in turn, drives a secondary chain running to the cams in each cylinder head. Lobes on the shaft activate two 5000-psi fuel pumps located in the engine’s valley, or vee. Another chain from the nose of the crank drives the seven oil pumps. One of those pumps distributes lubrication to the main bearings, the four camshafts, and the cylinder-bore oil squirters. Others evacuate the four sealed crankcase bays and drain-down cavities located at the front and the rear of the block.

Scrapers cast into the block in close proximity to the four counterweights skim oil off the crankshaft. The partial vacuum created by scavenging the lower crankcase in such a manner reduces the windage losses created when a crank spins through oil mist. Only half a quart of oil is circulating around the engine at any given time, even at peak rpm.

The head of the matter

LT6 heads are cast in A356 aluminum and heat-treated. Intake and exhaust ports are fully CNC-machined, as are the 12.5:1 combustion chambers. Each of the four valves above each cylinder is operated by a short finger follower located between each valve stem and the corresponding cam lobe. Oil squirters there keep all contact points well-lubed. Intake valves are titanium to save weight, while the stainless-steel exhaust valves are sodium-filled to help evacuate heat. Cast-iron valve seats are fitted for longevity. Direct fuel injectors are located outboard of the exhaust valves to promote air-fuel mixing as air tumbles into the combustion chamber. Each injector features six spray holes, laser-drilled to optimize the fuel mist pattern.

Variable valve timing improves both around-town drivability and high-rpm output. The timing of the intake valves can be adjusted by up to 55 (crankshaft) degrees, while the exhaust valves can be retimed up to 24 degrees. Two coil springs per valve prevent float at ultra-high rpm.

GM uses a robotic system to measure the thickness of each lash shim for the engine’s 32 valves. The engine assembler at the Corvette’s manufacturing plant, in Bowling Green, Kentucky, installs a shim under each finger follower; thanks to fastidious lubrication and minimal wear, GM claims that this setting will last the life of the engine. If a lash adjustment becomes necessary for any reason, the work can be accomplished by removing the camshafts.

An exotic breather box

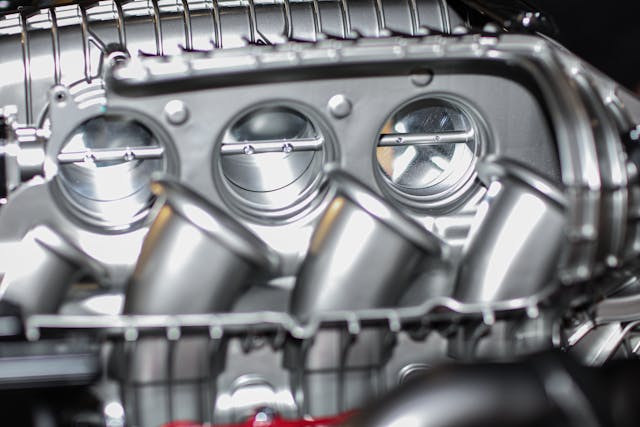

In order to produce its stupendous horsepower, the LT6 must inhale massive quantities of air. The two-piece intake manifold residing atop this V-8 brings to mind the black crown of an evil prince. Made of injection-molded, glass-reinforced nylon and stiffened with molded-in ribs, this manifold lives just above a pair of 87-millimeter throttle bodies. Each of the manifold’s two intake plenums has an internal volume of 5.5 liters, coincidentally identical to the LT6’s displacement. That huge size, crucial to power production, is enabled by the fact that mid-engine Corvettes carry their engines low, behind the driver; unlike on front-engine Vettes, C8 intake manifolds can be quite sizable without inhibiting driver visibility.

The good stuff is inside. Each plenum contains four molded intake-port extensions resembling small trumpets. Between the plenums live three servo-operated “communicator” valves; they take advantage of the pressure waves created inside the plenums every time an intake valve opens or closes, helping maximize engine output. Two of those valves share a common shaft, opening and closing in sync. The third one operates independently. One valve opens at around 2000 rpm. The others open on a schedule that varies with driving mode and rpm. All valves close shortly before the engine’s 8400-rpm power peak.

The net result: Four distinct communicator operating events inflate the LT6’s torque curve from 3500 rpm to 8600 rpm. The cylinders receive greater-than-atmospheric air pressure while running, with air volume exceeding piston displacement by 10 percent.

That constitutes 110-percent volumetric efficiency, virtually unheard of in naturally aspirated engines. This is essentially supercharging without the complexity of a crank- or exhaust-driven blower.

A landmark, for a landmark era

The LT6’s torque curve is essentially a flat line, with a subtle pip located at the engine’s 460 lb-ft, 6300-rpm peak. Combined with the astounding 670-hp at 8400 rpm, that stands as a new record for naturally aspirated V-8 engines, eclipsing the 622-hp achieved by Mercedes-Benz with its 6.2-liter, V-8-powered AMG Black Series coupes of 2013–2015. Energized by this new V-8, Z06 C8s are expected to click off the 0–60-mph run in just 2.6 seconds.

There’s more good news: The LT6’s son will be aimed at the upcoming Corvette ZR-1 and soon follow. That monster, logically labeled LT7, will offer twin turbos and at least 800 hp.

Given how the sun is setting on the internal-combustion era, it seems fitting to drag out the finest champagne and toast the arrival of these remarkable V-8s.

Oh great…now, I gotta build a flat-plane motor for #007. Seriously, I loved the article, Don.

It’s amazing how the acoustic tuning packs the cylinders 10% more…PASSIVELY. I thought it would have been dry sump, though…maybe the LT7???

Congratulations to Chevrolet for making America proud on the world stage of motorsports! Thank you.

The ZO6 engine is probably the last IC engine that will be developed by a US manufacturer. That is one reason why I am on a wait list for one to replace my 2021 C8. I don’t expect it until late 2024 or 2025. A long wait.

An engine cutaway illustration included within the article would have been nice… A chart showing hp and torque curves was necessary…

As for the sun setting on the internal- combustion engine is what a climate change subscriber mite say. We have yet to have a discussion on the toxic effects on the environment by EV batteries, recycle? disposal.

Renzo, I and all my friends are with you 100%.

I have a C6 Grandsport convertible and love it was all my heart! But while taking a walk near my home in Silicon Valley, less than 2 miles, I counted 36 Tesla’s in driveways or on the road! It appears they’re taking over, while battery and motor technologys are still developing. For about $100,000 you can buy Tesla’s most expensive, that claims 200 miles an hour and 0 to 60 in “1.999” seconds! (1/1000 of a second under 2 for brochure purposes!). Give the technology some time. I’m afraid silent, low maintenance, high torque from start is here to stay. But how about those electric bills?!