Getting rid of rumbles, vibrations, and whines

There are good car noises and bad car noises. Earlier this year, I wrote a two-part series about de-rattling and de-clunking your car. This time around, I’d like to augment that by talking about de-rumbling a car.

What’s the difference? Rattles and clunks are caused by things that are loose and are being bounced or shaken into motion. Rumbles, vibrations, and whines occur as a direct result of a component rotating—usually one in the drivetrain.

There’s another important distinction: With rattles and clunks, there is a nearly endless list of potential culprits, whereas there are only a few components in the drivetrain that rotate. Plus, you have the advantage that the pitch or volume of rumbles are almost always proportional to speed and/or engine RPM, making them, in theory, easier to find than rattles and clunks, which tend to be more road-surface related. However, rumbles can be maddeningly difficult to isolate, as sounds and vibrations tend to telegraph through a car body.

Let’s talk about speed-related vibrations first. The root causes of these are usually a wheel, rotor, or driveshaft. If a vibration gets substantially worse while braking, it’s probably an out-of-true brake rotor. This is commonly referred to as a “warped rotor,” although recent opinion has tilted toward the cause as being micro-deposits on or micro-imperfections in the rotor. If that vibration couples into the steering wheel during braking, it is almost certainly a bad front rotor. But it could also be a bent wheel. Simply jacking up the car, spinning the wheels, and checking the inner and outer lips for straightness is a remarkably effective method of identifying bent wheels.

If the wheels are straight, and you still feel a speed-related vibration through your seat bottom, you’re going to need to know if the problem is out-of-balance wheels and tires. Swapping the back and front wheels, or borrowing another set of wheels from someone, is easier and less expensive than any other vibration-related solution, so try that first. If the problem moves with the wheels, have the wheels and tires balanced.

But if you’ve ruled out wheels and tires, and you have a rear-wheel-drive car, the next likely source of vibration is the driveshaft. Many rear-wheel-drive cars have a familiar time-tested layout with a longitudinally-mounted engine and transmission, a differential at the rear of the car, and a driveshaft connecting them. There’s an output flange at the back of the transmission. The driveshaft may be directly attached to the transmission output flange, or may have a rubber flex disc interposed. The driveshaft usually has two universal joints, one at the output shaft of the transmission and the other at the pinion for the rear differential.

If the problem is less of a vibration and more of a dull rubbery thudding that reaches a crescendo at a certain speed, it’s likely that the rubber flex disc has cracked and is hitting something as it rotates faster and flies apart. Visual inspection is usually conclusive. If, instead, the sound is more of a metallic knocking, the bolts holding the front of the driveshaft to the flex disc, or the rear of the driveshaft to the differential, may have loosened up.

But if the problem is a vibration, and you’ve ruled out the wheels, it could be due to an out-of-balance driveshaft. Driveshafts, like wheels, need to be balanced. Thin curved weights are usually spot-welded in place during manufacture. Unlike wheel balancing, driveshaft balancing was thought to be a once-in-a-lifetime thing. However, 30, 40, 50, or 60 years after manufacture, it certainly is possible for a weight to fly off. In addition, with two-piece driveshafts, it is possible that, when separating the driveshaft halves to change a center support bearing, the two halves were not reconnected in their original orientation. Both of these things can throw a shaft out of balance and cause vibration.

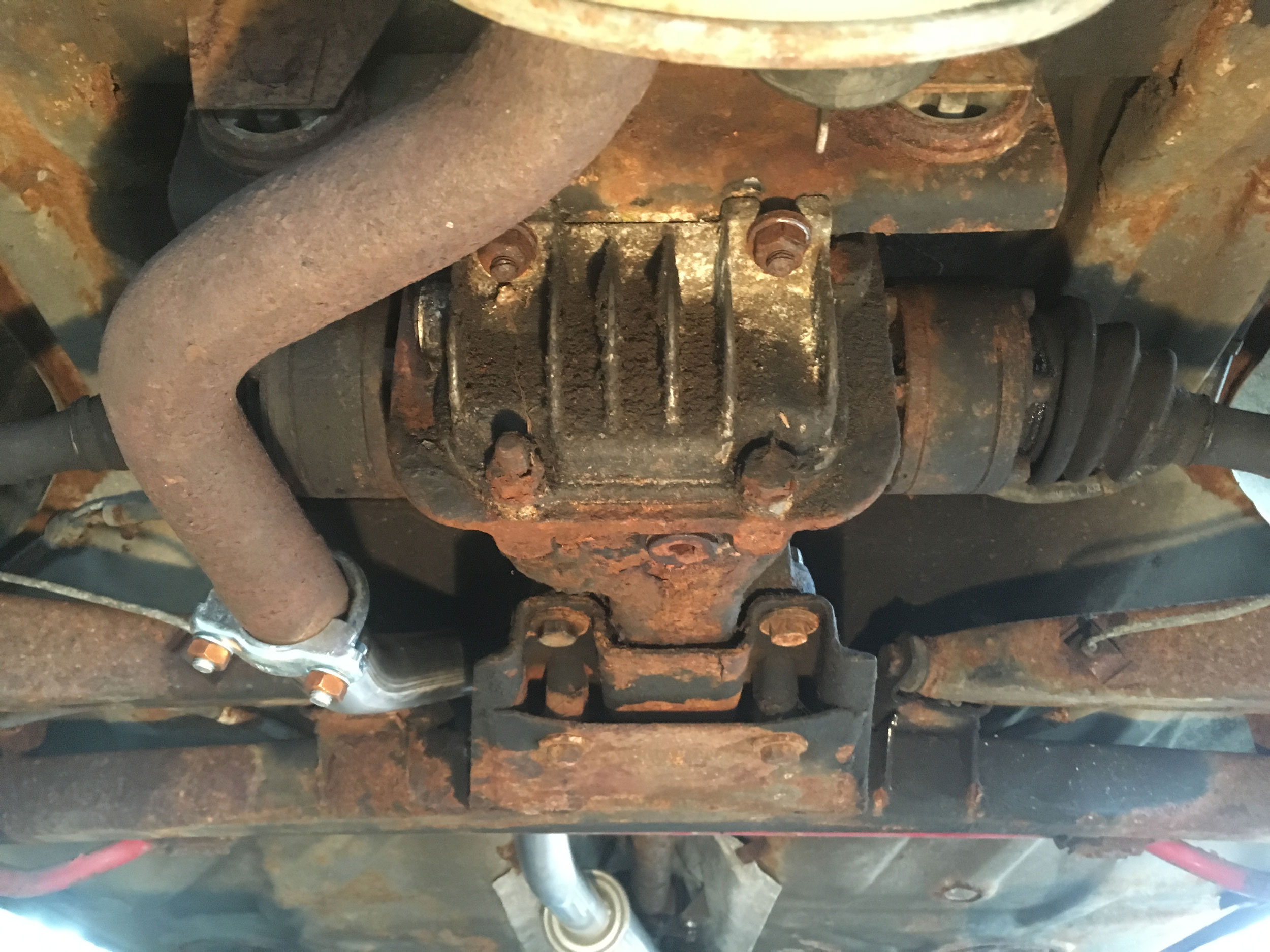

First, inspect the rubber mounts of the engine, transmission, and differential. If one of these has broken, it will cause that component to sit differently than designed, which likely will cock the driveshaft at an odd angle, which in turn can induce both vibration and noise.

Next, visually inspect the driveshaft to see if there are any light-colored rectangular patches indicating that a weight has fallen off. A driveshaft shop should be able to check the balance of your driveshaft and rebalance it if necessary. Be aware, though, that more and more the trend is for driveshaft shops to exchange your driveshaft for a reconditioned unit that is both rebalanced and has had the universal joints rebuilt. On the one hand, if you have to pull a driveshaft out, it’s a good idea to deal with any of its potential issues, but with rebuilt-exchanges in the $250–$350 range, it’s a stiff price to pay if you’re not certain that’s the problem.

The driveshaft is a natural point at which to segue from vibration issues to rumbling issues, as it is the drivetrain component that can exhibit both. Rumbling can come from the bearings in the transmission, driveshaft universal joints, differential bearings, and wheel bearings. Rumbling is notorious for telegraphing through the body of the vehicle, making it difficult to pinpoint its origin.

The best tools for nailing down the origin of a rumble is a lift and a mechanic’s stethoscope. If it is safe for you to do so, secure the car on the lift, following all of the manufacturer’s instructions to the letter. Connect a vent hose to the tailpipe of the car and exhaust it to the outside. Be certain that the space is extremely well ventilated to expel any exhaust that isn’t captured by the hose. Raise the lift, then start the car and put it in a low gear to spin the rear wheels. Secure your hair and any loose clothing, and go beneath the car, being extremely careful not to touch any rotating surfaces. If you don’t feel comfortable doing this, don’t do it.

Once under the running car, you may be able to isolate the source of the rumble with just your ears, or with a hose or a funnel to your ear concentrating the sound, but it’s often necessary to use the mechanic’s stethoscope and touch it to the rear trailing arms that house the rear wheel bearings, the body of the differential, and the back of the transmission. Hopefully one of these will be clearly and obviously noisy in the stethoscope.

I’m a firm believer in doing the easiest things first. If stethoscopic examination seems to implicate the driveshaft, pull it out. Then you can directly spin the center support bearing and feel the universal joints, checking them for quiet, smooth, play-free motion.

Of course, you can still get it wrong. I’ve had cars with just a little rumble and vibe that seemed to be in the driveshaft. I’ve pulled the driveshaft, didn’t see any missing weights or feel any bad U-joints, replaced the center support bearing, re-installed the driveshaft, and it made no difference; I still had noise and vibration. I later bit the bullet and ordered a rebuild-exchange shaft, and had the problem go away. Having to do this twice makes one more likely to get the rebuilt unit next time.

If there is indication that rumbling or whining is coming from the transmission or differential, before you go to the work to yank either of them out, do yourself a favor and check their fluid levels. In most cars, the transmission and differential both have a fill port and a drain plug. Be certain to loosen the fill plug first, because if you can’t get it out, you can’t fill it, in which case you shouldn’t drain it. You may find that the tranny or diff simply is low on fluid, and when filled, the rumbling or whining may go away. However, be aware that fluid does not simply evaporate from a closed gearbox, so if it’s low or empty, odds are that the fluid leaked out, and once you fill it, it may do so again. But at least you’ll likely see the source of the leak.

If fluids don’t solve the problem, and if you can’t pinpoint the source, you may need to begin unbolting components. Cars with independent rear suspension have the advantage that the half-axles can be unbolted easily from the wheel hubs. That way, the rear wheels can be spun by hand while you listen and feel if the rear wheel bearings rumble. If you suspect the noise is coming from the rear CV joints, it’s possible to unbolt the half axles from the differential and run the car to see if the noise goes away. Be aware, though, that noisy differentials can quiet down when there’s not an output load on them from the axles and wheels, so this isn’t a definitive test.

If the car has a whine rather than a rumble, it’s likely a gear whine, meaning it’s almost certainly coming from either the transmission or the differential. Whines that are specific to certain gears or pairs of gears essentially nail the source to the transmission, but whines from all gears may be either transmission or differential-related; search on an enthusiast forum for your car to learn the specifics.

As I keep saying, rumbles and whines can be maddeningly difficult to isolate. They can essentially throw their voices like a ventriloquist. It’s easier and quicker to replace a differential than a transmission, so if you’ve ruled out the driveshaft, CV joints, and wheel bearings, and have any doubt where the source of the noise is, start with the differential.

I recently had a vibration, rumble, and whine in a long-dormant BMW 2002. I swore that the whine and rumble were coming from the transmission; the whine was when on the gas, the rumble was when off it. The only thing that implicated the differential was a light rumble when coasting in neutral. I was unable to remove the differential’s fill plug, and I had a spare diff in the backyard, so I pulled it and swapped diffs. To my surprise and delight, all the rumbling and whining went away. None of it was coming from the transmission after all.

May you be as lucky as me in eradicating your rumbles and whines. And, to paraphrase The Beach Boys, may you only pick up good vibrations.

***

Rob Siegel has been writing the column The Hack Mechanic™ for BMW CCA Roundel magazine for 30 years. His new book, Just Needs a Recharge: The Hack Mechanic™ Guide to Vintage Air Conditioning, is now available on Amazon. You can also order a personally inscribed copy here.