American Speed Company’s Speed33 kit is hot rod heaven

The hot rod business is one of America’s best kept secrets. We drool on cue when the Ridler Award is presented at the Detroit Autorama and hold our collective breath when informed that CadMad, the 2019 winner, involved 15 years of effort, required some 4000 hours of craftsmanship, and consumed $2.3 million of the owner’s net worth. But CadMad is, literally, a once-per-fortunate-lifetime experience.

Contrast that with the thriving horde of coupes and roadsters still saluting ’30s-era design. Ford stopped making them ages ago. Virtually every shred of original factory metal has either dissolved to rust, been crushed and land-filled, or was long ago exhumed for rejuvenation. Yet fresh hot rods show up every cruise night and at the major custom shows around the country.

To explain a few hows and whys while delving into this semi-sub rosa business, we visited Phil Davie at the American Speed Company (ASC), located in Plymouth, Michigan, only 16 miles from Hagerty’s Ann Arbor editorial office. Inside this 10,000-square-foot shop, the American hot rod business is prospering.

Mark Trostle, a 40-year design veteran with stints at the Ford Motor Company, American Sunroof, and (currently) Roush Industries, founded ASC in 2007 to indulge his passion for hot rodding and to return a favor to the industry that had enriched his life with assignments ranging from Buick’s mighty GNX to Porsche’s 944 cabriolet. Trostle’s gambit was to use what he calls the “steel canvas” approach to construct brand new hot rod bodies. Instead of hand-crafting metal or molding fiberglass, ASC builds bodies using the newest and best techniques that exist in the Motor City and at every other major car manufacturer around the world.

It begins with two-dimensional thematic sketches drawn, in this case, by Trostle. After the design evolves into the best and final example of the artist’s dreams, the magic happens. Accurate front, side, and rear illustrations are converted to two-dimensional “blueprint” drawings. Then, with computer-aided-design (CAD) software tools such as Alias, CATIA, and Unigraphics, the design is scanned from paper to the computer screen. The final three-dimensional digital data is then used to guide water jets and/or milling machines to replicate the creation in full-size foam blocks for refinement if necessary. Once every detail is finalized, the digital data can be used to mill full-scale kirksite (a zinc-aluminum-alloy) dies for pressing flat sheets of steel into hot rod body panels. Detroit-area stamping shops employ the dies to make the panels under contract and they’re joined together by ASC using precise assembly fixtures.

ASC’s Speed33 is a brand new 1933 Ford Roadster updated here and there to suit contemporary hot rod needs and tastes. Metal gauges are heavier than original to insure high-quality fits, perfect surface finish, and indelible structural integrity. The original Ford wood body framing has been replaced by tubular steel internal reinforcements. Both the doors and the cab are longer to provide easy entry and room for today’s well fed owners. The dash panel is removable for customization and service. The stainless-steel windshield frame is chopped slightly, formed into U-channel shape, and canted back a bit for a racier appearance. The top is two-inches lower in height for convenient folding under a hinged cover panel. The beautifully polished windshield pillars begin as solid stainless-steel castings. The curved door glass is raised and lowered via electric motors and full molded-rubber weather sealing is included in the Speed33 kit.

The price of a bare body is $22,000. That rises to $29,750 with a folding top, fully functional doors (including side glass), and windshield assembly. While that price of entry is a bargain compared to recycling salvage yard metal, a finished hot rod can burn up $1 million if the goal is a top show car. Davie advises that even a nice ’32 Ford rendered in fiberglass can cost $100,000–$300,000 after the dust settles. To date, ASC has sold an amazing 154 Speed33 bodies, one of which ran 235 mph at Bonneville in 2009, another of which was a Great 8 (top contender) finalist at Detroit’s 2012 Autorama.

Davie is both ASC’s owner (since 2018), and the one and only craftsman in the building. On the day of our visit, he was hard at work on a project for Floridian John Wise and his son Scott. The goal is a car for cruising only—with full creature comforts but no major show expectations—with completion targeted by the end of this year. Gathering the parts and pieces began last summer. After paint and upholstery work, the project will be shipped south for the Wises to wrap up remaining details.

Davie acknowledges that this is a $200,000 (or so) project, half of which is attributable to parts, including the Speed33 body, and more than 1000 hours of his labor. (The shop rate, which is negotiable for repeat customers and special projects, is a reasonable $75/hour.) Here’s a list of a few suppliers for this particular Speed33:

- Chassis by Precision Hot Rods, including a Ford Mustang II front suspension, Kugel Komponents independent rear suspension, Wilwood disc brakes

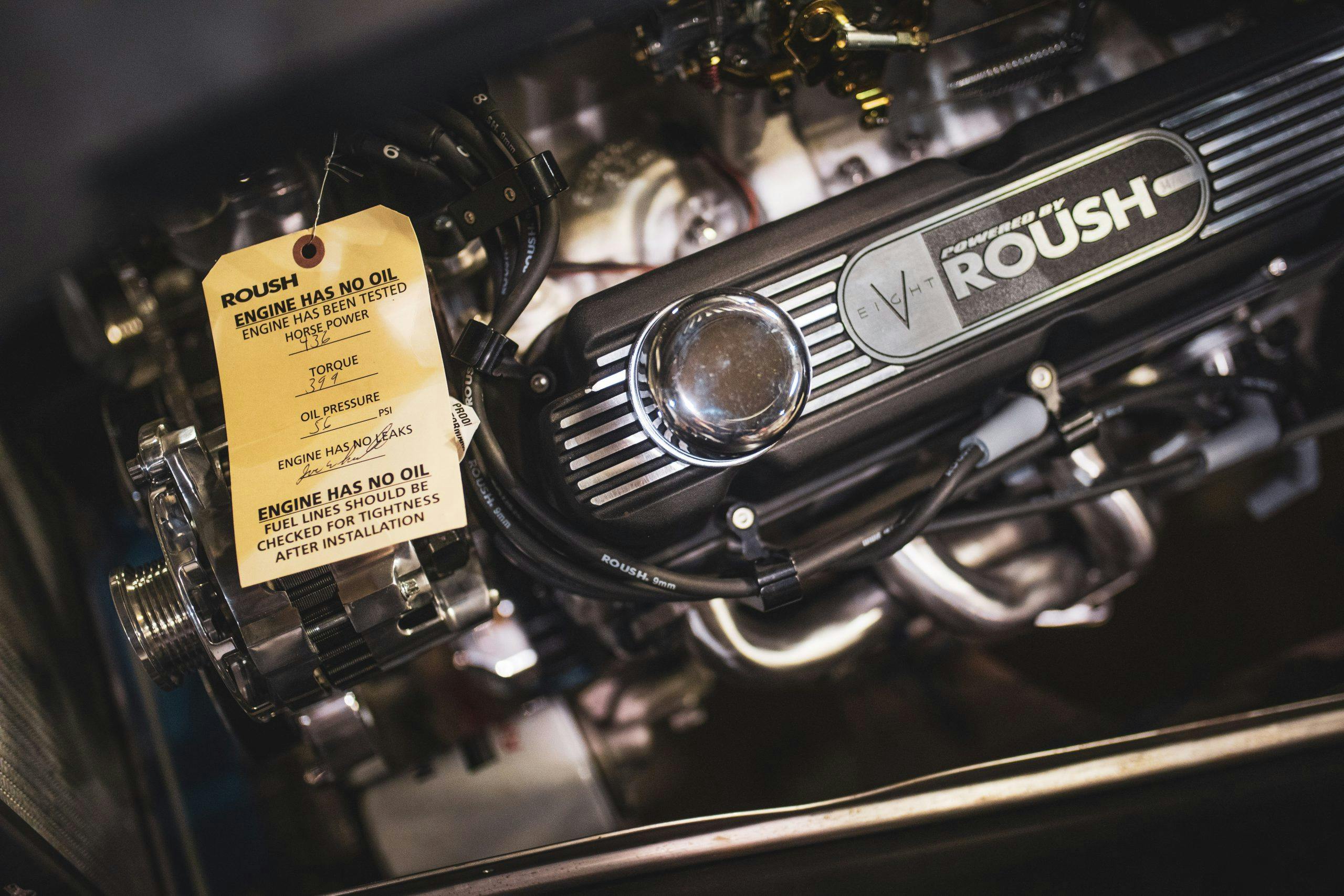

- Roush Performance 347-cu-in (stroked 302) Ford small-block V-8 engine delivering 436 hp and 399 lb-ft of torque, fed by a Holley four-barrel carburetor

- Sanderson Block Hugger exhaust headers

- Performance Rod and Custom aluminum radiator

- Rootleib hood

- ASC grille

- Wheelsmith 16-inch chrome-plated steel-laced wheels

- Coker American Classic radials, P185/70R-16 front, P235/70R-16 rear

- United Pacific Industries fenders and fuel tank cover panel

- Ididit steering column with Limeworks 16-inch banjo style wheel

- Classic Instruments gauges fitted to a modified 1933 Packard bezel

- Wiseguy bucket seats with six-way power adjustment

- Relicate butter rum top grain leather upholstery

- German-sourced black square-weave carpeting.

After the Wises wrap up this Speed33’s construction, we’ll check back in and hopefully be able to reveal exactly how their hot rod revival turned out.

Hagerty insures our classic cars. We began a speed 33 build with Phil Davie in Aug 2022, and the completion was 3 weeks ago on 3/3/23. We have paid him the full amount of $41,000 and car was to ship on 3/6 and have not received our car! As of 3/6/23 he stopped returning calls, texts or emails. We are reaching out to anyone that can help us put eyes on American Speed and our car.

We are having the same issue. We live in Maine and we are about to drive out there for some answer.

you suck at communication. i will not stop running you down till i get what we payee for. our registered letters and continues phone calls are going to continue till you contact us…this has been the worst purchase I’ve ever made…

did you ever get your car? i drove up and got my body but he did not have the parts. wondering how you fared out…

American Speed is awful, we ordered a car and have been months without answer. I email and call every day, is this company a scam?