From 2D design to 3D clay: Our industry insider peels back the studio curtain

Hello there! My name is Adrian Clarke. I am a professional car designer, earning a degree in automotive design from Coventry University and a Masters in Vehicle Design from the Royal College of Art in London. While I was there, one of my tutors was J Mays. (He used to bring in doughnuts.) I worked for several years at a major European OEM before the pandemic knocked the world into a cocked hat. In a previous life, in the Nineties, I daily drove a 1979 Ford Thunderbird while living in London.

In any area of industrial design, once the initial sketches are done, there’s always the step of building models and mock-ups from scratch. Car design is no different. Full-size models are necessary for understanding the 3D form, solving problems, and selling the design (especially to non-design literate management types). For example, we did a ridiculous, almost cartoon hard model of one of our cars with a cut-down windshield: A manager asked me if I thought the header rail (the top of the windshield) would be in my sightline (I am, as the late lamented Russell Bulgin would say, professionally tall at 6’2”). The only way to find out was to jump into the driver’s seat of the thing. You can’t do everything digitally!

Around 1910, aged 16 and on a family holiday in the Tehachapi mountains, north of his family home in LA, Harley Earl came across a canyon that had been flooded after torrential rainfall. Finding a small hollow that had become full of clay due to the rising water, Earl made some small tools out of wood and began using them to sculpt small model cars.

Earl was likely not the first person to use clay models in the design process; early coach builders had been using small-scale wood and clays to show their clients for a few years. But Earl was almost certainly on the vanguard when he mocked up four full-size clay models to demonstrate his ideas when hired as a consultant by GM to design the 1927 LaSalle for Cadillac. Nearly 100 years later, clay modeling is still a fundamental part the design process.

Bear in mind, modern automotive modeling clay is not really clay at all. It’s a kind of industrial plasticine—hard at room temperature and soft when warmed up. It gets everywhere (don’t wear your black suede Chelsea boots into the studio, ask me how I know) and due to the sulfur content, it stinks. The exact ingredients are closely guarded proprietary secrets, but a large manufacturer will go through a lot. Ford uses 200,000 pounds in a year, recycling as much material as possible.

Why use a physical material like clay at all? We now have the ability to sketch in 3D, so why not just build a model digitally, hand everyone a VR headset, and conduct reviews without even going to the studio? Surely this will be faster and more efficient?

Aside from the logistical difficulties of this strategy, not to mention the sheer computing horsepower required, any digital representation of a car is just that: a representation that’s filtered through a virtual camera lens and monitor. That’s simply not the same as the ol’ Mk1 human eyeball. Designers need time to reflect, think, and digest (usually over coffee) which is much easier when a physical object sits a few feet away from your desk. You can’t wheel a digital model outside to see how it looks in natural light (or pouring rain).

Car bodywork is sculpture. It needs to be touched and felt. The human hand is extremely sensitive to surface variation; you can’t judge the quality of a radius or a panel shut line by squinting at a screen. You need to run your fingers along it and feel the surfaces. Lamborghini famously doesn’t use clays and I’d argue it shows—its cars are either very rigid looking or a complete riot of clashing lines and angles with awkward transitions between surfaces. But not using clays saves them time and means it can churn out those multi-million dollar limited-run specials very quickly.

A clay model starts off as an armature (usually an aluminum frame), hard foam blocks making up the basic underlying volumes of the car, and plastic wheel arch openings. Modelers then spend a couple of days liberally coating this contraption with clay by hand, known as “laying up.” What emerges is a very rough, brown-colored car shape like something a toddler would make out of Play-Doh. When ready, it’s wheeled onto one of several “clay plates” that take up the majority of space in the studio.

A calibrated metal floor with an accompanying 5 axis milling arm (not strictly 5 axis, but that’s what they’re known as), a studio will have a number of these arranged in a line under longitudinal fluorescent lighting tubes hanging from the ceiling. Over the course of a few days and nights, the milling machine will make several passes over the model, starting off rough and getting more accurate with each pass. It’s then finished off by hand, smoothing off the main surfaces and correcting any small mistakes. And it can be milled to a high resolution; you can mill in things like windows seals and roof guttering and clay will hold its edge fidelity.

The real advantage of clay is in its versatility. Clays are working models, constantly updated as details and surfaces change over time. If large changes are required, they can be re-milled from updated surface data. Clay modelers use a heat gun (think an industrial-grade hair dryer) to soften an area and add more material or subtract it, or to rework an edge to the tape line. Designers use Rinrei tape, (made in various widths from Japanese rice paper, that doesn’t leave a residue) to tape lines on the models, to work out shut lines, feature lines and block out graphics like lights and vents. And yes, designers really do that arm-outstretched-holding-a-tape-on-a-model pose that you’ve seen before. This is to look along the line of tape to make sure it’s correct.

To resemble painted sheet metal, clay models can be covered in a film called Di-Noc, made by 3M. Thicker than the usual vinyl wrap used by customizers, it’s applied wet and can be stretched and heated to adhere perfectly to the clay surface. This allows designers to judge the quality of the highlights across the body work.

Wheels can initially be simple print-outs on paper taped to a black foam tire, then as the design evolves there are secondary wheels used that can have different designs attached to them, so that variations can be reviewed in situ. The width is also adjustable so designers can pull the wheels out as far as legislation allows and to check things like sidewall profile to help minimize curb damage. When one of our new cars was launched the Chief Designer took delivery of his (before the customers naturally) and promptly sent it away. The next day it came back fitted with spacers to shove the wheels out further.

Lights, mirrors, door handles, trim pieces and wipers can be added as hard parts later. Milled out of high density foam or 3D printed, then painted, they contribute to making the model look as real as possible. These parts go through many iterative updates—the aero team might tell you your mirror design is directing rain water over the side glass so it needs to change shape. So it’s simple to knock out a new part and simply swap it over on the clay model.

As the design nears completion, the clay may be painted, using the exact shades that will be used on the real cars. This gives the Color, Materials, and Finish team the chance to view the color palette and make sure it works on a car, not just as a swatch on a mood board.

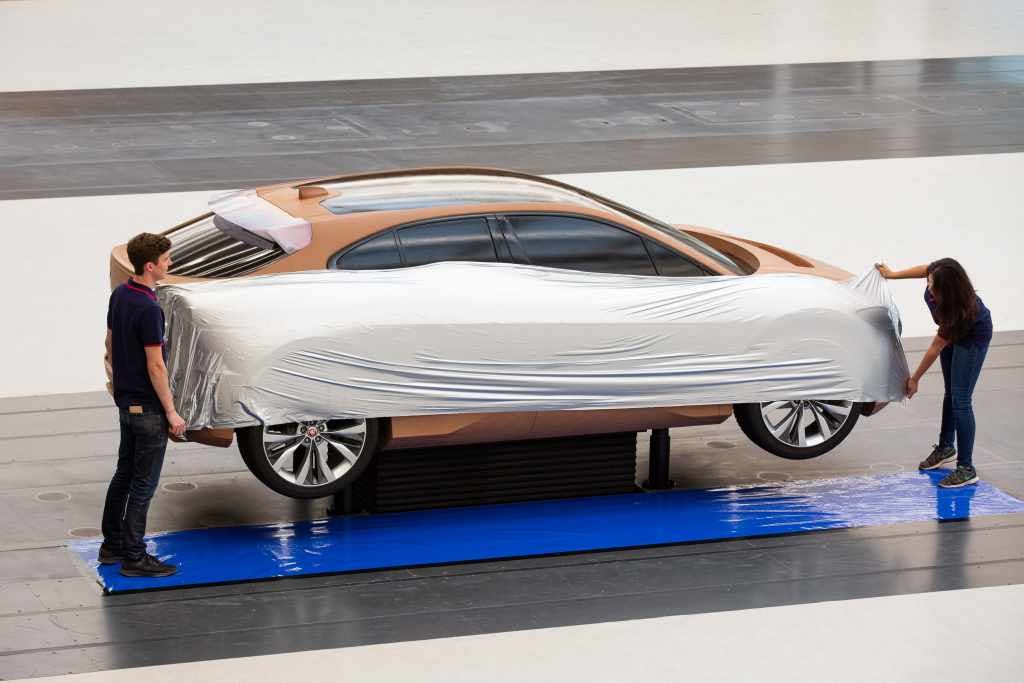

The ultimate in design studio deception is the full-size hard model. These are extremely time consuming and costly to make, so they are used at very specific points—normally when the design vision is frozen (the master recording), or if the studio has come up with an idea on its own and wants approval to proceed.

Made out of resin and GRP, with Plexiglas windows and machined metal details where appropriate, they are painted to the same standard as production cars, mounted on real wheels and tires and used to wow the higher-ups—this is what we are going to make. One car I worked on had three variations of roofline and door count. Although ultimately only one went forward to production, it showed what could be possible in the future. Larger studios will have the capacity to make hard models themselves, but smaller satellite studios might not: Nissan Design Europe (in London’s Paddington Basin) for example, doesn’t. There are companies that can do it for you from your data, but expect a bill of seven figures depending on complexity. These “vision” models only have a rudimentary interior—what is known as a half board—only what is visible above the door frames will be represented, the rest covered by you’ve guessed it, a board over the interior tub. (The interior team will have their own clay and hard models.)

Reference models, made at the end of the realization process when all the engineering and production feasibility work is finished, are indistinguishable from the real car. They’ll be shown to dealers, journalists, and VIPs as part of the launch build up. They have working lights, opening doors and tail gates, a full interior, instrumentation and may have electric motors or be built on an existing chassis with an ICE to allow slow speed trundling around. Their hand-finished nature means they need constant checking to make sure everything matches production data. Trudging to the workshop and paint booths meant I got a lot of walking in (and regularly covered in paint and filler dust) supervising the building of two of these types of reference model.

If you’re thinking that these processes sound a lot like a how concept cars are made, you’re right. Concept cars are done in exactly the same way, because they too are expensive hand built one offs. Only that concepts don’t have to adhere to annoying details like production feasibility, business cases, or legislation compliance, which is why if they get turned into production models their appearance changes to take these things into account.

In the next article we’ll look at how the design vision is turned into production reality and what goes into getting it on the road. We’ll also explain why even at the last minute before production starts the designer still plays an important role.